Aluminium Alloy Crewed Flange

| Min. Order: | 500 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 10000 Piece/Pieces per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Custom Gravity Casting Connection, Aluminum Alloy Auto Parts, Aluminium Alloy Hardware Parts, Aluminium Alloy Assembly Parts, Alloy Aluminium Sand Casting Parts |

Product Detail

| Model No.: | Ketai |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Weight: | 5-10 Kg |

| Applicaion: | Auto Parts |

| Place of Origin: | Zhejiang, China (Mainland) |

| Material: | Aluminium Alloy(Al-Si) |

| Surface Treatment: | Sand blasting |

| Processing: | Low Pressure Casting |

| Brand of Material: | A356 |

| Heat Treatment: | T6 |

| Tolerance: | H8,+0.033mm. |

| Color: | metallic/Silver |

| Production Capacity: | 10000 Piece/Pieces per Month |

| Packing: | Standard exporting packing or as per customer's requests |

| Delivery Date: | 45-50days |

Product Description

Product Name: Aluminium Alloy Crewed Flange.

The largest DIA: 500mm.

What is Low Pressure Casting?

Low-pressure Casting is named by methods for filling the mold cavity. Low-pressure Casting uses 5 to 15 psig (35 to 100 kPag) of air pressure to force liquid metal up a feed tube into the mold cavity. This eliminates turbulence found in gravity casting and increases density, repeatability, tolerances, and grain uniformity. After the casting has solidified the pressure is released and any remaining liquid returns to the crucible, which increases yield.

Equipment: There are 3 low pressure casting production lines.

J452 Low Presssure Machine

J452 Low Presssure Machine

J453 Low Presssure Machine J458 Low Presssure Machine

Payment Terms:

1. Payment for tooling: pay 50% in advance ,and samples will delivery within 50days, after confirmed the samples pay the balance 50%

2. Payment for goods: Pay 30% in advance ,after deliver the goods ,see B/L copy pay the balance 70%.

CNC:

Ningbo Ketai Industry Co., Ltd has CNC and Technicians. Machined as customers' requirements.

Ningbo Ketai Industry Co., Ltd has CNC and Technicians. Machined as customers' requirements.Aluminiun Alloy List:

CHINA

GB/T 1173

INTERNATIONAL ATANDARD

ISO 3522

GERMANY

DIN 1725.2

ENGLAND

BS 1490

FRANCE

NF A57-105

JAPAN

JIS H5202

AMERICA

ASTM B179

ZAlSi7Mg(ZL101)

Al-SiMg(Fe)

G-AlSi7Mg

LM25

A-S7G

AC4C

356

ZAlSi7MgA(ZL101A)

Al-SiMg

G-AlSi7Mg

LM25

A-S7G

AC4C

356A

ZAlSi12(ZL102)

Al-Si12

G-AlSi12

LM20

A-S13

AC3A

413.2

ZAlSi9Mg(ZL104)

Al-Si10Mg

G-AlSi9Mg

__

A-S9G

AC4A

359

ZAlSi5Cu1Mg (ZL105)

Al-SiCu1Mg

G- AlSi5Cu

LM16

__

AC4D

355

ZAlSi5Cu1MgA(ZL105A)

Al-Si5Cu1Mg

G- AlSi5Cu

LM16

__

AC4D

355.2

ZAlSi8Cu1Mg (ZL106)

Al-SiMg(Fe)

__

LM24

A-S7G

AC4B

328.1

ZAlSi7Cu4(ZL107)

Al-Si6Cu4

G- AlSi6Cu4

LM21

__

AC2B

319.2

ZAlSi12Cu2Mg1 (ZL108)

Al-Si12Cu

G-Al Si12(Cu)

LM13

A-S13

AC3A

383.2

ZAlSi12Cu1Mg1Ni1(ZL109)

Al-Si12Cu

G-Al Si12(Cu)

LM13

A-S13

AC3A

A413

ZAlSi5Cu6Mg (ZL110)

Al-Si16Cu4

G- AlSi6Cu4

LM21

__

__

308

ZAlSi9Cu2Mg (ZL111)

Al-Si10Mg

G- AlSi8Cu3

LM2

A-S9G

AC4B

354

ZAlSi7Mg1A(ZL114A)

Al-Si7Mg(Fe)

G-AlSi7Mg

LM25

A-S7G-03

AC4C

357

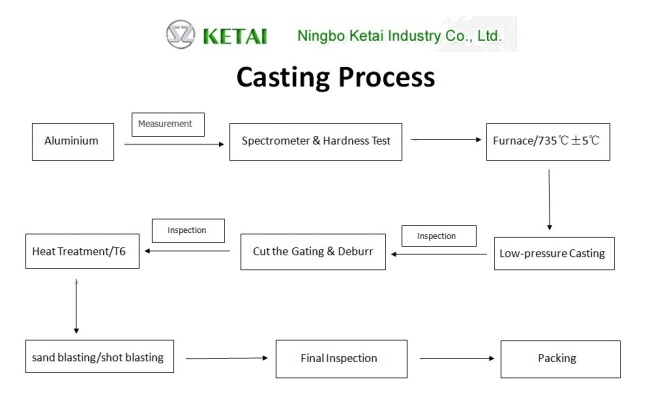

Casting Process:

Casting Method: low pressure casting.

Welcome to vist our factory!