Low pressure Casting of Pump Components

| Min. Order: | 500 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 2000 tons/per year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Custom Gravity Casting Connection, Aluminum Alloy Auto Parts, Aluminium Alloy Hardware Parts, Aluminium Alloy Assembly Parts, Alloy Aluminium Sand Casting Parts |

Product Detail

| Model No.: | Aluminium Pump Valve Components |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Tolerance: | H8,+0.033mm |

| Materia: | Aluminium Alloy |

| Brand of Material: | ZL104 |

| Surface Treatment: | Sand blasting |

| Weight: | 10-15Kg |

| OEM service: | Available |

| Casting Process: | Aluminium Low pressure Casting |

| Casting Core: | Multiple Cores |

| Cylinder: | Tricylinder |

| Heat Treatment: | T6 |

| Production Capacity: | 2000 tons/per year |

| Packing: | as requirments |

| Delivery Date: | 45-50days |

Product Description

Product Name: Low pressure Casting of Pump Components

Payment Terms: Tooling charge pay 50% in advance ,and samples will delivery within 50days, after confirmed the samples pay the balance 50%. Payment for goods pay 30% in advance ,after deliver the goods ,see B/L copy pay the balance 70%.

The company covers an area of more than 10 thousand square meters and owning more than 60 sets of varied equipment.

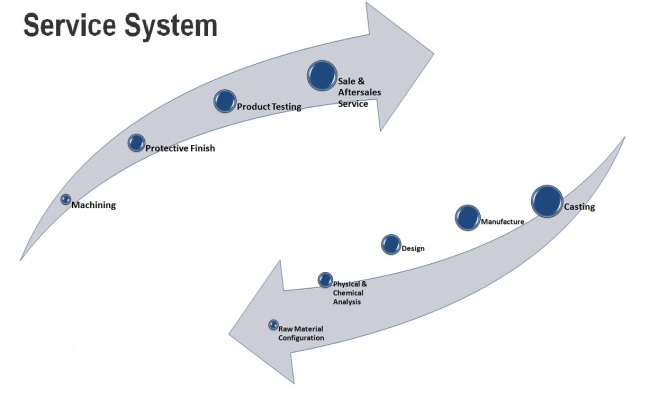

Service System:

Strict quality contral for evert batch. Each part has been got 30% test and final has 100% inspection.

High quality with low price, timely delivery.

Established in 1991, Backed by China Weapon Reserch Institute Ningbo Branch.More than 20 years.

Aluminiun Alloy List:

CHINA

GB/T 1173

INTERNATIONAL ATANDARD

ISO 3522

GERMANY

DIN 1725.2

ENGLAND

BS 1490

FRANCE

NF A57-105

JAPAN

JIS H5202

AMERICA

ASTM B179

ZAlSi7Mg(ZL101)

Al-SiMg(Fe)

G-AlSi7Mg

LM25

A-S7G

AC4C

356

ZAlSi7MgA(ZL101A)

Al-SiMg

G-AlSi7Mg

LM25

A-S7G

AC4C

356A

ZAlSi12(ZL102)

Al-Si12

G-AlSi12

LM20

A-S13

AC3A

413.2

ZAlSi9Mg(ZL104)

Al-Si10Mg

G-AlSi9Mg

__

A-S9G

AC4A

359

ZAlSi5Cu1Mg (ZL105)

Al-SiCu1Mg

G- AlSi5Cu

LM16

__

AC4D

355

ZAlSi5Cu1MgA(ZL105A)

Al-Si5Cu1Mg

G- AlSi5Cu

LM16

__

AC4D

355.2

ZAlSi8Cu1Mg (ZL106)

Al-SiMg(Fe)

__

LM24

A-S7G

AC4B

328.1

ZAlSi7Cu4(ZL107)

Al-Si6Cu4

G- AlSi6Cu4

LM21

__

AC2B

319.2

ZAlSi12Cu2Mg1 (ZL108)

Al-Si12Cu

G-Al Si12(Cu)

LM13

A-S13

AC3A

383.2

ZAlSi12Cu1Mg1Ni1(ZL109)

Al-Si12Cu

G-Al Si12(Cu)

LM13

A-S13

AC3A

A413

ZAlSi5Cu6Mg (ZL110)

Al-Si16Cu4

G- AlSi6Cu4

LM21

__

__

308

ZAlSi9Cu2Mg (ZL111)

Al-Si10Mg

G- AlSi8Cu3

LM2

A-S9G

AC4B

354

ZAlSi7Mg1A(ZL114A)

Al-Si7Mg(Fe)

G-AlSi7Mg

LM25

A-S7G-03

AC4C

357

Casting Process:

Welcome your inquiry! We believe that we will be your ideal partner!