Sand Casting of Hardware Accessory

| Min. Order: | 500 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10000 Piece/Pieces per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Custom Gravity Casting Connection, Aluminum Alloy Auto Parts, Aluminium Alloy Hardware Parts, Aluminium Alloy Assembly Parts, Alloy Aluminium Sand Casting Parts |

Product Detail

| Model No.: | Machinery Accessory |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Price: | 400RMB-700RMB |

| Maching: | As requirements |

| Weight: | 10-15 Kg |

| Surface Treatment: | Short Blasting |

| Color: | metallic/Silver |

| Material: | Aluminium Alloy |

| Place of Origin: | Zhejiang, China (Mainland) |

| Usage: | Agricultural Fittings |

| Brand of Material: | ZL101A |

| Heat Treatment: | T6 |

| Production Capacity: | 10000 Piece/Pieces per Month |

| Packing: | as customers' requirments |

| Delivery Date: | 45-50days |

Product Description

Product Name: Sand Casting of Hardware Accessory.

Certificate: ISO9001:2008.

Precision Machined, tolerance: H8,+0.033mm.

Cooperate with Germany Cooper Company, American Dover Group, Australia SFA Company, Germany Siemens Company, Austrial Rosenbauer Company, Philips Company ect.

Weight: 10-15 Kg.

Ningbi is closed to Zhoushan Islands and Hangzhou Bay, it has convenient communications via ocean. Also there are various National Airlines, at the same time, it is next to Shanghai.

Achieved a good reputation at domestic and overseas with competitive price and goog quality, high quality and on-time delivery.

Aluminiun Alloy List

CHINA

GB/T 1173

INTERNATIONAL ATANDARD

ISO 3522

GERMANY

DIN 1725.2

ENGLAND

BS 1490

FRANCE

NF A57-105

JAPAN

JIS H5202

AMERICA

ASTM B179

ZAlSi7Mg(ZL101)

Al-SiMg(Fe)

G-AlSi7Mg

LM25

A-S7G

AC4C

356

ZAlSi7MgA(ZL101A)

Al-SiMg

G-AlSi7Mg

LM25

A-S7G

AC4C

356A

ZAlSi12(ZL102)

Al-Si12

G-AlSi12

LM20

A-S13

AC3A

413.2

ZAlSi9Mg(ZL104)

Al-Si10Mg

G-AlSi9Mg

__

A-S9G

AC4A

359

ZAlSi5Cu1Mg (ZL105)

Al-SiCu1Mg

G- AlSi5Cu

LM16

__

AC4D

355

ZAlSi5Cu1MgA(ZL105A)

Al-Si5Cu1Mg

G- AlSi5Cu

LM16

__

AC4D

355.2

ZAlSi8Cu1Mg (ZL106)

Al-SiMg(Fe)

__

LM24

A-S7G

AC4B

328.1

ZAlSi7Cu4(ZL107)

Al-Si6Cu4

G- AlSi6Cu4

LM21

__

AC2B

319.2

ZAlSi12Cu2Mg1 (ZL108)

Al-Si12Cu

G-Al Si12(Cu)

LM13

A-S13

AC3A

383.2

ZAlSi12Cu1Mg1Ni1(ZL109)

Al-Si12Cu

G-Al Si12(Cu)

LM13

A-S13

AC3A

A413

ZAlSi5Cu6Mg (ZL110)

Al-Si16Cu4

G- AlSi6Cu4

LM21

__

__

308

ZAlSi9Cu2Mg (ZL111)

Al-Si10Mg

G- AlSi8Cu3

LM2

A-S9G

AC4B

354

ZAlSi7Mg1A(ZL114A)

Al-Si7Mg(Fe)

G-AlSi7Mg

LM25

A-S7G-03

AC4C

357

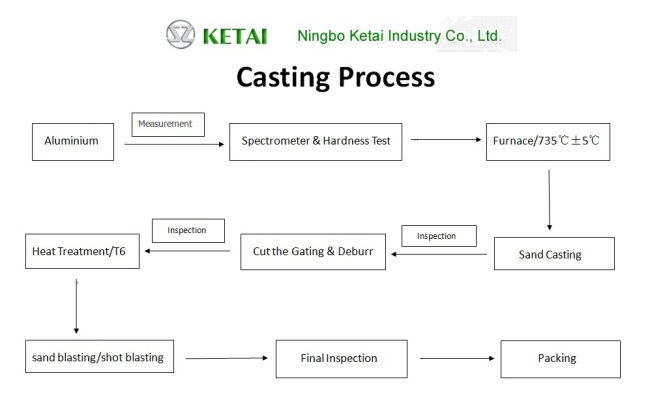

Casting Process:

Ningbo Ketai Industry Co., Ltd. is worth your attention.