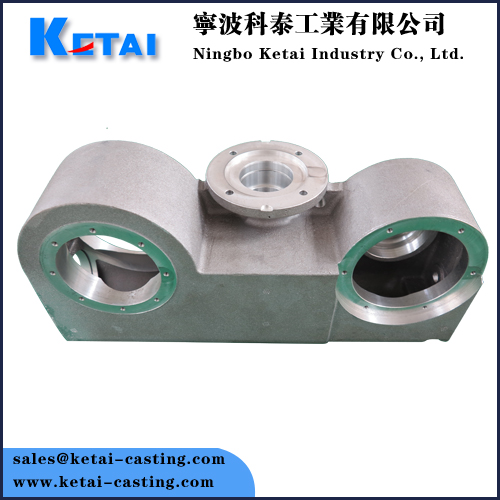

double cylinder of sand casting

| Min. Order: | 200 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 10000 Piece/Pieces per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Custom Gravity Casting Connection, Aluminum Alloy Auto Parts, Aluminium Alloy Hardware Parts, Aluminium Alloy Assembly Parts, Alloy Aluminium Sand Casting Parts |

Product Detail

| Model No.: | Auto Parts |

|---|---|

| Means of Transport: | Land |

| Brand Name: | Ketai |

| Weight: | 10-20Kg |

| Maching: | As requirements |

| cylinder: | double cylinder |

| Casting Core: | multiple cores |

| Casting Method: | Sand Casting |

| Material: | Aluminium Alloy |

| Usage: | Machinery Fittings |

| Brand of Material: | 356 |

| Heat Treatment: | T6 |

| Surface Treatment: | Sand blasting |

| Production Capacity: | 10000 Piece/Pieces per Month |

| Packing: | as customers' requirment |

| Delivery Date: | 45-50days |

Product Description

Product Name: double cylinder of sand casting.

Show:

Casting Method : Sand Casting

Quality Principle: Quality First, Customer Above All. Company Idea: Deal with the concrete matters relating to work, explore. high efficiency and keep Promise.

Property:

Weight

10-20kg

T6

Machined

As requirements

Material

Aluminium Alloy

Usage

Agricultural Fittings

Material

356

cylinder

double cylinder

Surface Treatment

Short Blasting

Aluminiun Alloy List with Brand of different countries.

CHINA

GB/T 1173

INTERNATIONAL ATANDARD

ISO 3522

GERMANY

DIN 1725.2

ENGLAND

BS 1490

FRANCE

NF A57-105

JAPAN

JIS H5202

AMERICA

ASTM B179

ZAlSi7Mg(ZL101)

Al-SiMg(Fe)

G-AlSi7Mg

LM25

A-S7G

AC4C

356

ZAlSi7MgA(ZL101A)

Al-SiMg

G-AlSi7Mg

LM25

A-S7G

AC4C

356A

ZAlSi12(ZL102)

Al-Si12

G-AlSi12

LM20

A-S13

AC3A

413.2

ZAlSi9Mg(ZL104)

Al-Si10Mg

G-AlSi9Mg

__

A-S9G

AC4A

359

ZAlSi5Cu1Mg (ZL105)

Al-SiCu1Mg

G- AlSi5Cu

LM16

__

AC4D

355

ZAlSi5Cu1MgA(ZL105A)

Al-Si5Cu1Mg

G- AlSi5Cu

LM16

__

AC4D

355.2

ZAlSi8Cu1Mg (ZL106)

Al-SiMg(Fe)

__

LM24

A-S7G

AC4B

328.1

ZAlSi7Cu4(ZL107)

Al-Si6Cu4

G- AlSi6Cu4

LM21

__

AC2B

319.2

ZAlSi12Cu2Mg1 (ZL108)

Al-Si12Cu

G-Al Si12(Cu)

LM13

A-S13

AC3A

383.2

ZAlSi12Cu1Mg1Ni1(ZL109)

Al-Si12Cu

G-Al Si12(Cu)

LM13

A-S13

AC3A

A413

ZAlSi5Cu6Mg (ZL110)

Al-Si16Cu4

G- AlSi6Cu4

LM21

__

__

308

ZAlSi9Cu2Mg (ZL111)

Al-Si10Mg

G- AlSi8Cu3

LM2

A-S9G

AC4B

354

ZAlSi7Mg1A(ZL114A)

Al-Si7Mg(Fe)

G-AlSi7Mg

LM25

A-S7G-03

AC4C

357

Param of 356 used in this product.

Aluminium Alloy

Si

Cu

Mg

Mn

Ti

Fe (S)

Cu

Zn

Tensile Srength

(σb/MPa)

Elongation

(δ5/%)

HBS

356/Al-SiM(Fe)

6.5-7.5

__

0.25-0.45

≤0.35

__

≤0.5

≤0.2

≤0.3

≥225

≥1

≥70

Casting Process:

Machining

9. Sample Room

10. Welcome to view & scan our website and build business relationship with us. Your feedback will be highly appreciated.