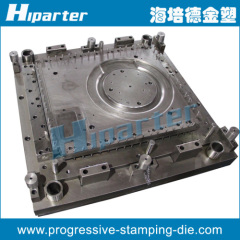

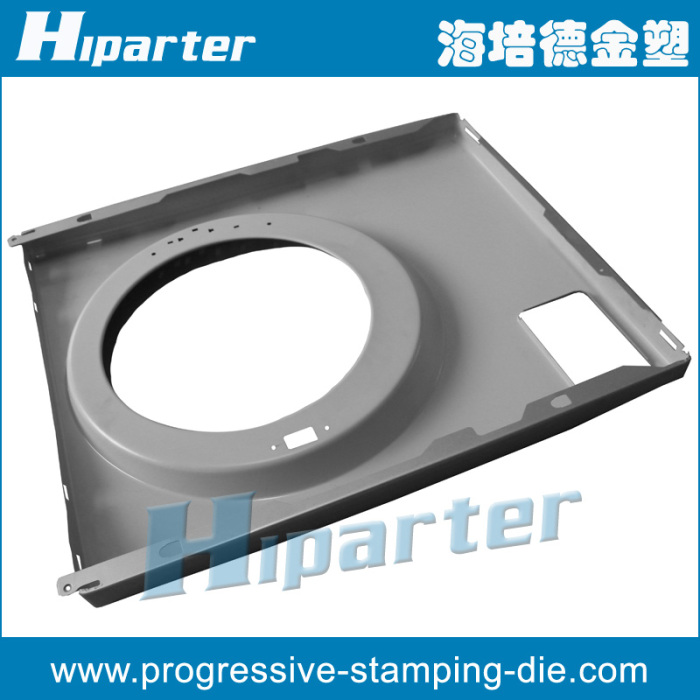

Stamping mold and stamping mould for washing machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 sets per month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Stamping Die |

Product Detail

| Model No.: | HPDJZ0036 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Product: | Household Appliance |

| Product Material: | Metal |

| Shaping Mode: | Punching Mold |

| Brand Name: | Hiparter |

| Spare part: | MISUMI standard |

| Mold life: | 1 million shots |

| Mold tolerance: | 0.02mm |

| Die procedure: | Single stage mold |

| Mould material: | DC53 |

| Part material: | PCM,SUS430 |

| Experience: | Over 13 years |

| Equipment: | EDM,Wire Cutting,CNC |

| Certification: | ISO9001:2008 |

| Press machine: | 200Ton |

| Production Capacity: | 50 sets per month |

| Packing: | Plywooden case |

| Delivery Date: | 50 days after die structure confiemed |

Product Description

Detailed introduction to stamping mold and stamping mould for washing machine:

Qingdao Hiparter Metal&Plastic; Products Co,.Ltd, a famous stamping die manufacturer in Qingdao, north of China. We are professional in home appliance products stamping mold, especially stamping mold and stamping mould for washing machine, such as washing machine metal front door, washing machine top panel, washing machine metal flange, washing machine bottom wheel......

Product material:SUS430 for washing macchine flange and bottom wheel,PCM for washing machine front door

Thickness:0.5mm

Mold material:Alloy copper and DC53 for the punch and inserts to ensure the mold life

Die life: More than 1 million shots

Total procedure: Total 5 steps

Press machine: 200T for stamping mold

Rich expereice in making stamping mold and stamping mould for washing machine

ISO9001:2008 certificated by SGS

High quality one-stop service

Supply die detail structure drawing to customer

Signed confidentiality agreements to protect customer property

Our advantages:

In-time response on letters, telephone calls or fax

In-time supply the quotation and mould designs

In-time communication on the technical points

In-time sending pictures for the mould machining progress and mould finishing schedule

In-time mold test and sample delivery

In-time mold delivery

Tool trial press machine capacity: 45T~400T, including one 315Ton Hydraulic machine,we can do the all trial works in our own factory

Contact Details:

Get more information about stamping mold and stamping mould for washing machine metal part, please visiti Qingdao Hiparter Metal&Plastic; Products Co.,Ltd, and please contact Project Manager Jack Zhao.

.jpg)