China microwave oven metal part stamping die maker

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 sets/month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Stamping Die |

Product Detail

| Model No.: | HPDZ4452 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Product: | Household Appliance |

| Product Material: | Metal |

| Shaping Mode: | Punching Mold |

| Brand Name: | Hiparter |

| Die procedure: | Progressive stamping die |

| Mold life: | More than 500,000 shots |

| Die material: | SKH51,Cr12Mov |

| Part material: | Galvanized sheet |

| Tolerance: | 0.02mm |

| Spare part: | MISUMI standard |

| Die base: | Homemade by steel plate |

| Cavity: | Single cavity |

| Surface treatment: | Polishing |

| Experience: | Over 12 years |

| Production Capacity: | 50 sets/month |

| Packing: | Plywooden case |

| Delivery Date: | 35 workdays after die structure drawing confirmed |

Product Description

China microwave oven metal part stamping die maker

Company Information:

Building time: built in 2003, over 12 years rich experience for die making

Location: we are located in Chengyang District, Qingdao, China, Which is very near from the Qingdao Liuting International Airport, only 15 minutes for driving. So, it is very convenient for your visiting our factory.

Area: 20,000 square meters

Employees: about 300 staffs, with a professional working team

Certification: ISO9001:2008 by SGS

Main equipment: about 55 sets, including CNC, WEDM-LS, Bending machine, Milling Machine, Press Machines and so on

Plants: 5 workshops, including die making, stamping parts fabrication, parts assembling and so on.

Inspection: CMM, vision projector, depth guage, altimeter, durometer

Die design: 2D/3D Software (Pro-E, UG, SolidWork, AutoCAD, CAE etc.)

Design: We have our own tooling design department. There are 23 design engineers. 10 engineers for stamping dies, 13 engineers for plastic moulds.

Capability: stamping dies including stage stamping die, progressive die, transfer die are all acceptable

Export Markets: North America, South America, Europe, Asia, Africa, Brazil, Japan, Korea, Egypt, etc

One stop service----product design, die design, die manufacture, production of products. Plating, painting, and so on.

Production: about 40 sets dies monthly

Technology support: Free. English, Korean, German can be acceptable

Customer: KIA, TOYOTA,SUZUKI, GM, Haier, Hisense, Sanyo, Siemens etc.

Exporting: 70% , Our dies exported over 30 countries, from USA, Mexico, Japan, Iran to Germany, UK, Egypt, South Africa, to India, Russia, Brasil, Argentina etc.

Products Description:

Parts | Automotive parts, home appliance, electrical, mobile phone, metal construction parts, communication parts and so on |

Thickness | 0.16-10mm |

Type | Sheet or coil |

Hardness | Soft, half hardness, full hard 280HRC … |

Procedure | Bending, flanging, piercing, blanking, riveting, trimming, drawing… |

Tolerance | +/- 0.01mm |

Max.part length | over 2m |

Part drawing | 2D,3D |

Die type | Stage die, progressive die, transfer die, casting forming |

Material type | Cold sheet steel, stainless steel, zinc plated, color metal, tin plate, 65Mn, non metal, fiber… |

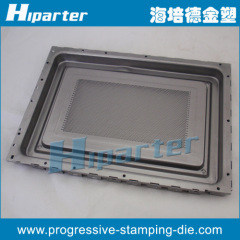

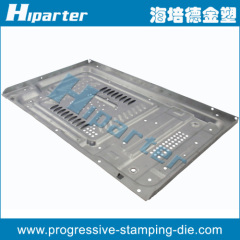

Microwave oven door panel stamping die

Microwave oven top panel metal stamping die

Microwave oven progressive stamping die for metal part

Contact us:

If you want to get more information about microwave oven stamping die and our company,please feel free to contact us by email or a phone,we will feedback any questions within 24 hours.Welcom to visit us.