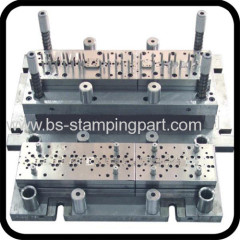

Metal clamp ring progressive stamping die

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 20 |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Stamping Die |

Product Detail

| Model No.: | HPDZ2235 |

|---|---|

| Means of Transport: | Ocean, Air |

| Product: | Household Product |

| Product Material: | Steel |

| Shaping Mode: | Punching Mold |

| Brand Name: | Hiparter |

| Die procedure: | Progressive die |

| Mold life: | Over 1 million shots |

| Die material: | SKH-9,SKD11,Cr12Mov |

| Spare part: | MISUMI standard |

| Part material: | SUS304 |

| Thickness: | 0.3mm |

| Tolerance: | 0.01mm |

| Cavity: | Single cavity |

| Certification: | ISO9001:2008 |

| Market: | Global |

| Production Capacity: | 20 |

| Packing: | 1 |

| Delivery Date: | 40 |

Product Description

Rich experience | More than 12 years |

Part material | SPCC, DC01, DX51D+Z, SUS etc. |

Die/tool material | AMPCO25,ASP-23, D2, SKH-9, SKD11, etc. |

Cavity | Single / Multi-cavity |

Tool life | At least 1,000,000 shots |

Spare parts | FIBRO, MISUMI, PUNCH, Dayton, etc. |

Software: | AutoCAD, PRO/E, Solid works, UG(NX) |

Main equipment | Milling, Grinding, Boring, CNC, EDM, WEDM, etc. |

Die Precision | 0.02mm |

Drawing format | .igs, .step, .x_t, .pdf, .dwg, .dxf, |

Lead time | First trial of die in 15~40 days after die construction confirmed |

Punching press | From 6T to 400T |

Metal clamp ring stamping die

Stainless stell stamping part for clamp ring

Progressive stamping die for clamp ring

Part material:SUS304 thickness:0.3mm

Proccessing

When we get your inquiry for the products stamping dies, we will do as follows,

1.Inquiry | You can send us your drawings or samples for quotation, 2D & 3D drawing are both acceptable. |

↓ | |

2.Quotation | We offer the quotation according to your parts structure, mold requirements, quantity ... |

↓ | |

3.Make an order | We have an agreement with each other after communication. |

↓ | |

4. Mold design | Our engineers design the mold strucuture with CAD, and we send it for your confirmation. After you think it ok, we will start to order the material and make a build plan for this project. |

↓ | |

5.Mold Fabrication | According to the progress, we start the mold with the CNC machine center and W-cut, grinding etc. |

↓ | |

6. Mold Trial | We will make the mold trial, and offering 2-5 samples when the mold spproved |

↓ | |

7. Leaving factory | Delivery mold by sea or by air, according to your need |