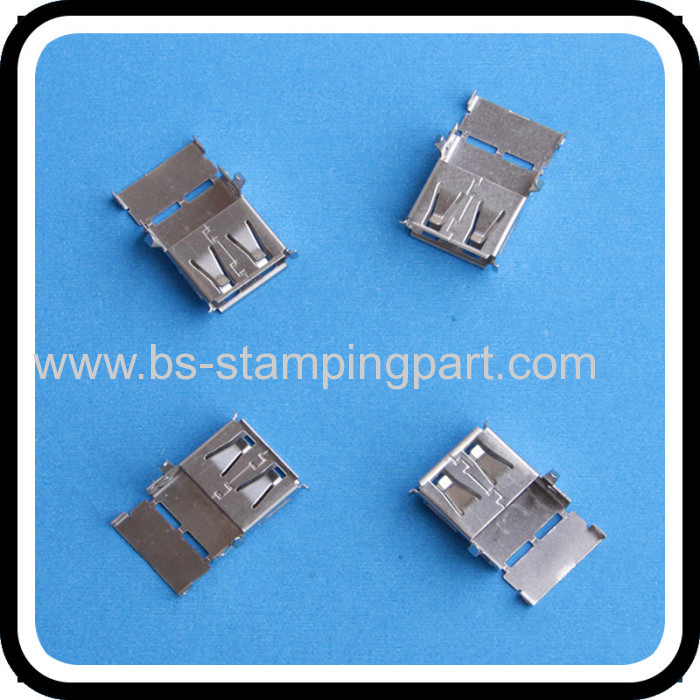

Customized stainless steel USB connector for mobile phone

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 50000pcs/week |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Dongguan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Stamping Part, Precision Shrapnal, Deep Drawing Part, Ball Bearing Track, Metal Terminal |

Product Detail

| Model No.: | BS122802 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Model No.: | Custom |

| material: | stainless steel |

| Size: | Customer's drawing |

| process: | stamping |

| usage: | mobile phone |

| quality control: | qc |

| certificate: | ISO9001:2008 |

| Package: | plastic box |

| color: | bulk |

| finish: | no |

| Production Capacity: | 50000pcs/week |

| Packing: | bulk, tray, tape and reel |

| Delivery Date: | 8-15days |

Product Description

1. Information of company product

1) We usually quote metal precision stamping price according to the product's specific dimension drawings or 3D drawings, material, thickness, surface finish, quantity or sample from customers. Pls refer the below relative metal precision stamping photos first:

2) Advanced facilities, with CNC, EDM, wire-cutting, Milling Machine, Grinding Machine, High-speed Pressing and other high-tech equipments.

3) Used for PCB shielding gaskets

4)Material : Becu, Beryllium copper

5)Fast delivery for Becu emi shielding finger strips

6)OEM stamping parts

7) ISO9001:2008,SGS.

8)We own factory&advanced equipment

9)Reasonable price and good service.

10) property: soldering

| A:Raw Material | Becu, Beryllium Copper,phosphor copper,Brass, Copper,Stainless steel,Aluminium ,SGCC,SECC,steel,spring steel,Nickel-Silver... and all different kinds of metal ; |

| B.SPEC | Roll material thickness is 0.05-10mm;sheet metal thickness is 0.3-20mm; |

| C.Surface treatment | Gold / Silver /Tin / Nickel / Zinc / Chromium / Copper-plating / Laser etching/Screen printing/Phosphating (can pass salt spray testing with 160 hours)/Black coating / Painting/ Power coating /Electrophoresis / Passivating /Deburring / Polishing / Brush acording to ROHS standard; |

| D.Application | All different kinds of telecom products,Automotive,high-end digital cameras,Medical Equipment, Remote,Washing machines , vacuum cleaners,desk lamp,Furniture, Switch Power Supply,Socket,water heater,High-end toys,Calculator,Electrical,Interphone, Wireless Mouse, Wifi Router,Cordless telephone,mobile phone,Mobile DVD,Sounder.Auto Clutch,bicycle brake,scooter and so on ; |

| E.Quotation | Please provide the Formal drawings (normally,with DWG/STP/PDF file ),and make note with material/QTY/surface treatment and any other requirments, we will provide you the quotation sheet in 48-72 hours; |

| F.Prototype & Mould | We make the prototypes or moulds according to the drawings that confirmed by both of us and customers!The lead time is depends on the structure and qty of parts,Normally , lead time for prototypes is 3-15 days;leat time for mould is 10-25 days; |

| G.Production | We will provide samples according to the drawings to customers for approval . then arrange the production and confirm the delivery date according to the Purchase Order;Normally , the lead time for production is 5-30 days ,the structure of parts is different , the lead time will be different . |

| H.Package | Plastic bags;Preserving Box;Reel/tape package;Plastic tray;Wood box;Export carton and any other customized package according to the customers' requests. |

2. Company Profile

A: Over 20 years professional technology in mould design, mould making, metal parts' making;

B: 10 years experience in developing and export in foreign trade;

C: Passed ISO9001:2008

D: All materials meet ROSH, certificates for materials are available;

E: Capacity can be 200K-800K PCS each day.

3.Factory Live & Showing of Complete Production Equipments

The office -> meeting room -> mould room -> workshop -> testing room.

4.Technology Process

Mould design->wire cutting-> mold assembly->stamping->testing-> packing.

5.Certificates

ISO9001:2008 and SGS or ROHS

6.Process of Mould & Products

Bosi company also keep the management idea of quality first and service foremost, establish professional product development team to perfect quality control process and inspection equipment.

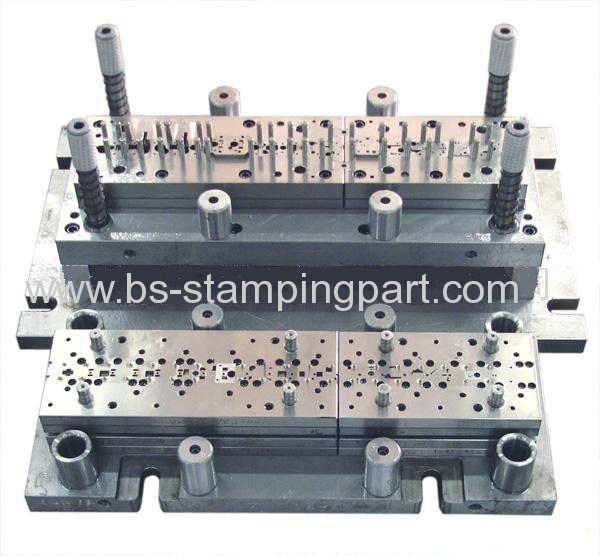

Mould reference picture:

Mould making proces:

Stamping production process flow diagram:

7. Our Service

A: Promptly reply to enquiries within 24 hours;

B: Try our best to solve problems or questions for you, with our professional team;

C: Quick response, within 24-48 hours, to 8D reports of abnormality, or dealing of defective products;

D: 99.5% rate of delivery on time;

E: 99.9% percents of pass for samples or products.

10. How to place an order ?

A. Sending us inquiry from via Alibaba or send your letter to our company uniform mailbox (pls refer the next one information)or contact us by TM (Trademanager) directly;

B. Offering 3D drawing or specific dimension drawings or samples,for a quotation. we also could design it according to your specific requirement of materials, thickness,surface finish, packaging etc;

C.I reported it to our engineer and manager confirm and quote for it, then I send the quotation to you, and you send the PO to us after you accept or talk with us be ok, next, we will send the PI to you and you pay for it in advance, Our factory proceed with ready and test mould and proofing;

D. Confirming all of the terms, such as delivery time, payment terms, package, shipping way etc;

E. Sending the samples to customers' for testing;

F. Starting mass production after samples approved;

G. Notification of shipping time;

H. After-sales Service and Client feedback.