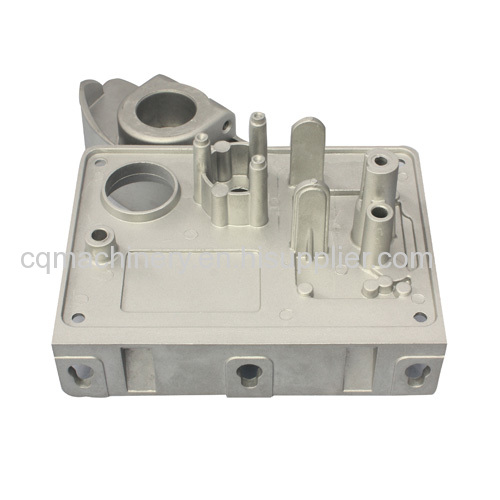

die casting pumps accessories

| Min. Order: | 2000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100/day |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Fastening Piece, Pipe Fitting, SS Auto Tubing Connector, SS Auto Non-standard Sl-eeve, Die Casting Auto Accessories |

Product Detail

| Model No.: | CQ050 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | OEM |

| Material:: | Aluminium |

| Surface treatment:: | According to the customer's requirements |

| Port loading:: | Ningbo or Shanghai |

| Export Area:: | All over the world |

| MOQ:: | 2000 pcs |

| Color:: | Natural |

| Package:: | Carton |

| Delivery time:: | 45 days |

| Production Capacity: | 100/day |

| Packing: | carton |

| Delivery Date: | 45 days |

Product Description

Pump is to transport liquid or liquid pressurized machinery. Transfer mechanical energy or other external energy to the liquid it is the prime mover, the liquid energy increases. Pump is mainly used to transport water, oil, acid and alkali liquid, emulsion, suspension emulsion and liquid metals and other liquids, but also transport liquid, gas and liquid mixture containing suspended solids. Pumps are usually divided according to the working principle of positive displacement pumps, power pumps and other types of pumps categories. Except works classification, but also by other methods of classification and naming. For example, the method can be divided according to the driving electric pump and turbine pumps, etc.; according to the structure can be divided into single-stage pump and multi-stage pumps; press use can be divided boiler feed pumps and metering pumps, etc.; according to the nature of transmission fluid can be divided into pumps, mud pumps, and so on.

In the chemical and petrochemical sector production, raw materials, semi-finished and finished products are mostly liquid, raw materials and semi-finished and finished products will need to go through a complex process, played a transmission fluid pump and pressure flow provides chemical reactions in these processes the role, in addition, the device is also used in many pump to adjust the temperature.

In agricultural production, the pump is the main irrigation machinery. Rural vast, rural areas will require substantial annual pumps, agricultural pumps generally accounted for more than half of the pump output.

In the mining and metallurgical industry, the pump is also the most used devices. Need to pump mine drainage, beneficiation, smelting and rolling process, required to pump water supply.

In the power sector, nuclear power plants need nuclear main pump, two pumps, three pumps, thermal power plants need

To a lot of boiler feed pumps, condensate pumps, circulating pumps and ash pumps.

In defense construction, aircraft flaps, rudder and landing gear adjustment, warships and tanks turret rotation, ups and downs and so need submarine pump. Pressure and radioactive liquids, and some also require a pump without any leakage.

In short, whether it is aircraft, rockets, tanks, submarines, or drilling, mining, trains, ships, or everyday life, everywhere need to use a pump, the pump is running everywhere. It is so, so the pump as general machinery, the machinery industry which is a major product category

Pump spare parts

Pneumatic diaphragm pump is a diaphragm pump is a new type of transportation machinery, using compressed air as a power source for all kinds of corrosive liquid with particles, high viscosity, volatile, flammable, poisonous liquid , can be pumped exhaust, has formed a production, product quality and well received. The main feature of this pump is that no irrigation water, pumping both liquid flow, but also is easy to transport some of the flow of medium, high suction lift, lift adjustable (0-50 meters) greater than the air pressure only 1kg / cm2 that is able to work, absolutely fire-proof, with a submersible pump, pump, trash pump, shield pump, many features of mud all functions and transport machinery.

A diaphragm composition and classification

Diaphragm pumps known control is the main type of the actuator, the control unit outputs a control signal by receiving the adjustment means to change the power-operated fluid flow. Generally diaphragm actuator and valve components. If by their enforcement agencies use, the diaphragm can be divided into pneumatic, electric, hydraulic three, namely pneumatic diaphragm pump compressed air power source to power as a power source for electric diaphragm pump, the liquid medium (such as oil) pressure-powered electric hydraulic diaphragm pumps, in addition, their functions and features points, as well as solenoid valves, electronic, smart, fieldbus type diaphragm pump. Diaphragm many types of products, structures are also diverse, but also constantly update and change. Generally speaking valve is universal, both matching and pneumatic actuators can also be matched with electric actuator or other executive agencies.

2 diaphragm type selection

2.1 diaphragm valve type selection diaphragm valve of choice is to select the most important aspects. Many types of diaphragm valve, commonly used through single-seat, two-seater 10 kinds of straight, angular, diaphragm, low flow, tee, eccentric rotation, butterfly sleeve, ball and so on. Before selecting a valve, you want to medium, process conditions and parameters control the process of careful analysis, to collect enough data to understand the system requirements on the diaphragm, according to the data collected to determine the type of valve to be used. In the specific choices available from the following considerations:

(1) Spool shape of the structure is mainly based on the selected flow characteristics and unbalanced forces and other factors considered.

(2) wear resistance when the fluid medium is a suspension containing a high concentration of abrasive particles, valve, valve seat joints every closed will be subject to serious friction. Therefore, the valve flow path to be smooth, the valve inside the material to be hard.

(3) corrosion as a corrosive medium, to meet regulatory function in the case, try to choose a simple valve.

Temperature (4) media pressure when the medium temperature, high pressure and great change, should be chosen disc and seat materials affected by temperature and pressure changes in a small valve.

to prevent steam and air steam and air only in a liquid medium. In the actual production process, steam and air not only affects the calculation of flow coefficient, but also the formation of vibration and noise, so that the shorter the life of the valve, thus preventing the valve in the valve should be selected to produce steam and air

lubrication pump without oil

Electric type

Electric pump, i.e. a pump driven by electricity. Electric pump is a pump, Yang pipes, pumps seats, submersible motor (including cable) and start protection devices and other components. Pump is a submersible pump working parts, which consists of the inlet pipe, diversion shell, check valve, pump shaft and impeller and other component parts. An impeller fixed to the shaft in two ways.

1. Displacement pumps

Caused by the movement of the working volume of the working parts and reducing the periodically increased suction fluid and the working member by directly pressing the pressure of the liquid can be increased.

Depending on the movement pattern of moving parts is divided into: reciprocating pump and the rotary pump types.

Depending on the structure of moving parts: Piston pumps and piston pumps, gear pumps, screw pumps, vane pumps and water pump.

2 impeller pump

Impeller pump impeller is driven by high-speed rotation and fluid transfer mechanical energy to the liquid conveyed.

The pump impeller and runner structural characteristics of different impeller can be divided into: 1) Centrifugal pumps

2) axial flow pump

3) mixed-flow pump

4) vortex pump

3 jet pumps

Is generated by the high velocity jet of working fluid entrained flow body then is increased by the momentum exchange energy entrained flow leaving the body.

Pump shaft position can also be divided into:

1) vertical pumps

2) Horizontal pumps

Divided by the number of suction:

1) single-suction pumps

2) double suction pump

Pump driven by the prime mover of points:

1) motor pump

2)steam turbine pump)

3) diesel pump

4) diaphragm pump

Automatic lubrication pump (Pulsarlube M automatic oiler) is an American high-tech products. Pulsarlube M automatic oiler stored in the microprocessor according to the time running a small reducer, worm gear drive located inside the pump through vertical reciprocating piston suction / spray container grease.

Lubrication pump is a lubrication equipment, supplies lubricant to lubrication. Mechanical devices require periodic lubrication, lubrication of the main ways is based on previous work status of the equipment, after reaching a certain artificial lubrication maintenance cycle, such as the popular saying beat the butter. Lubrication pump maintenance work can make this easier. Divided into manual lubrication pump lubrication pump and electric lubrication pump.

Automatic lubricating device can effectively reduce equipment failure, reduce energy consumption, improve production efficiency and extend machine life.

A variety of specifications distributor, supply all kinds of friction to achieve accurate; combined lubricating valve block can be conveniently fix the system design, and can be production requirements change, so that the most economical consumption of lubricant.

Progressive lubrication distributor can withstand continuous 20 Mpa pressure, up from the conveyor lubricant, its advanced structure effectively prevents the backflow of oil due to its own weight.

Oil lubrication device manufacturing sophisticated, perfect performance, quality class, is essential for the maintenance of centralized lubrication systems. Multifunctional monitoring component that can accurately and timely monitoring of the lubrication points (friction) of the operating conditions, reported a machine fault location.

Species

Lubrication pump, manual lubrication pumps, electric lubrication pump, pneumatic lubrication pumps, feed pump, automatic lubrication pumps, hydraulic, lubrication pumping stations, oil mist lubrication, oil lubrication, lubrication devices. Lubricating device product lines with more than eighty approximately more than six hundred specifications, lubrication systems, lubrication components, fuel systems, a full range of lubricating machinery products and accessories.

Our factory:

We can produce all kinds of die casting parts. please send us the drawing or sample. we will quote the competitive price to you.

Welcome to visit our company.