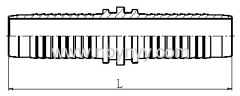

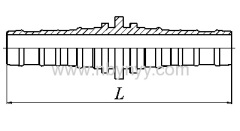

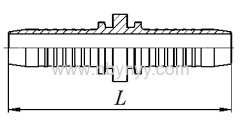

Hydraulic press connector fitting

| Min. Order: | 3000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1500 pcs /day |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Fastening Piece, Pipe Fitting, SS Auto Tubing Connector, SS Auto Non-standard Sl-eeve, Die Casting Auto Accessories |

Product Detail

| Model No.: | CQ024 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Machine Type: | Others |

| Type: | Others |

| Brand Name: | OEM |

| Material:: | Carton steel |

| Surface treatment:: | according to our customer's requirements. |

| Port of loading:: | Ningbo or Shanghai |

| Export Area:: | all over the world |

| MOQ:: | 3000 pcs |

| Color:: | Natural |

| Package:: | Carton |

| Delivery time:: | 30 days |

| Production Capacity: | 1500 pcs /day |

| Packing: | carton |

| Delivery Date: | 30 days |

Product Description

Hydraulic machine from the cylinder, Bottom, pistons, piston rods, cylinder heads, seals, cushioning unit and exhaust system components.

Hydraulic machine (aka: hydraulic machine) is a hydraulic machine to machine metal, plastic, rubber, wood, powder and other products, machinery use hydrostatic pressure. It is commonly used in the pressing process and press-forming process, such as: forging, stamping, cold extrusion, straightening, bending, flanging, drawing sheets, powder metallurgy, pressure equipment and so on.

Its principle is to use a lot of Pascal's law made use of a mechanical transmission fluid pressure, species. Of course, the purpose is also varied according to need. If the pressure of the liquid by passing the type of points, there are hydraulic machines and hydraulic press two categories.

The total pressure generated by a large hydraulic press, commonly used in forging and stamping. Forging hydraulic press is divided into forging hydraulic press and freedom of forging hydraulic press two kinds. Die forging hydraulic machine to use, but do not die free forging hydraulic press. The first 10,000 tons of China's manufacturing hydraulic press is free forging hydraulic press.

all kinds of hydraulic press connector

With a hydraulic working fluid medium for transfer of energy to achieve various process machines. Except for the hydraulic forging forming, but also can be used for correction, pressure equipment, packaging, plate clamps and the like. Hydraulic machine includes hydraulic press and hydraulic press. Water-based liquid as the working medium is called hydraulic press to oil as the working medium is called a hydraulic machine. Hydraulic specifications generally work with a nominal force (kN) or nominal tonnage (tonnes) said. Forging hydraulic machine is a hydraulic press, the higher the tonnage. To reduce the size of the equipment, large forging hydraulic press used high pressure (35 MPa or so), sometimes with more than 100 MPa high pressure. Other uses hydraulic machines generally use 6 to 25 MPa working pressure. Lower than the tonnage hydraulic machine hydraulic machine

Brass hydraulic press connector

Drive System

Hydraulic drive system has a direct drive pump and the pump - accumulator drive two types. This drive system is a direct drive pump pumps provide high pressure working fluid to the hydraulic cylinder, with the liquid supply valve is used to change the direction of the pressure relief valve to regulate defined systems, while the overflow from the security role. This drive system is part of a small, simple structure, able to automatically increase or decrease the pressure at the desired operating force, reduced power consumption, but by the maximum force and the maximum operating speed of the work machine to determine the capacity of the hydraulic pump and its drive motor. This type of drive system used for small and medium sized hydraulic machines, direct drive pump is also useful for large (eg 120 000 kN) free forging hydraulic press.

Pump - drive storage system in which a driver or a group of the accumulator. When the supply of high-pressure fluid pump has margin, stored by the accumulator; And when insufficient supply when necessary, they supplement supplied from the accumulator. Such a system can be selected using the average amount of high-pressure working fluid capacity of the pump and the motor, but because of the pressure of the working fluid is constant, the power consumption is large, and part of the system, the structure is relatively complicated. This drive system is used for large hydraulic machine, or a drive system with several sets of hydraulic machines.

Structure type

Distinguish the direction of the force, hydraulic machine has vertical and horizontal. Most of vertical hydraulic press, hydraulic extrusion machine is multi-purpose horizontal. By structure type, hydraulic machine has double-column, four-, eight columns, welded steel frame and multi-frame and other types of wound, medium and small vertical hydraulic press as well as with the C-frame. C-frame hydraulic press three sides open, easy to operate, but poor rigidity. Stamping with a welded frame type hydraulic machine rigidity, before the open, but so closed. Vertical transmission poster on free forging hydraulic press, cylinder fixed on the beam, a rigid connection between the plunger and the moving beam, the beam from the column-oriented activities, under pressure to move up and down the role of the working fluid. There can be moved around the table on the beam. In active beams and were installed on the anvil work surface and lower anvil. Frame work force from the upper and lower beams and columns consisting bear. Using a pump - accumulator drive big, medium-sized free forging hydraulic press often uses three cylinders to get the three work force. There is also a balance of work outside the cylinder cylinder cylinder and return upward force is applied.

Technical Reference

Normal pressure | kn | 3150 |

Liquid Maximum pressure | mpa | 31 |

Slide stroke | mm | 400 |

The maximum opening height | mm | 650 |

Column center distance (left or right ×back front) | mm | 800×500 |

Table effective area (left or right ×back front) | mm | 700×700 |

Table Dimensions (left or right ×back front) | mm | 1000×700 |

Table height | mm | 680 |

Machine covers | mm | 2150×900 |

Machine height | mm | 2400 |

powder | kw | 11 |

Shaft (shaft) is worn on the middle or intermediate gear wheel bearings or cylindrical object in the middle, but there's a small part of the square. Supporting the rotating shaft is rotating parts and therewith to transmit motion, torque or moment of mechanical parts. Generally round rod-like metal, can have different diameters for each segment. The rotary movement of the machine part mounted on the shaft.

Common crank shaft, straight shaft and shaft three.

Direct axis can be divided into: ① shaft, both at work and bear bear torque moment, is the most common mechanical axis, such as a variety of reducer shaft. ② mandrel for supporting only rotating parts rather than bending moment transmitted torque, and some spindle rotation axis such as a rail vehicle, the spindle is not rotating and some, such as the pulley support shaft. ③ shaft, mainly used to transmit torque without bending moment, such as cranes long axis moving mechanism, a drive shaft automobile. Shaft material used mainly carbon steel or alloy steel, ductile iron or iron alloy may also be used, such as. Generally depends on the ability to work the shaft strength and stiffness, high speed depends on vibration stability.

Materials used

1, carbon steel

35,45,50 other high-quality carbon structural steel for high mechanical properties, more applications, of which 45 steel used most widely.

In order to improve its mechanical properties, should be normalized or quenched. Unimportant or minor axis by force may be applied Q235, Q275, such as carbon steel.

2, alloy steel

Alloy with high mechanical properties, but more expensive, and more for the special requirements of the shaft.

Such as the use of high-speed shaft bearings, common 20Cr, 20CrMnTi other low-carbon alloy steel, after carburizing journal can improve the wear resistance;

Generator rotor shaft at a high temperature, high speed and heavy load conditions of work, you must have good high temperature mechanical properties, often used 40CrNi, 38CrMoAlA such as alloy structural steel.

In forging the blank shaft priority, followed round;

Size large or complex structures may be considered cast or ductile iron.

For example, ductile iron crankshaft, camshaft, with low cost, good vibration absorption, low sensitivity to stress concentration, better strength and so on.

Mechanical model is the beam axis, the majority to be rotated, so the stress is usually symmetrical loop.

The possible failure modes are: fatigue fracture, overload fault, such as excessive elastic deformation.

Shaft pulley hub usually install some parts, so most of the shaft shall be made stepped shaft, cutting large.

Our factory:

We are specialized in nonstandard machinery connectors and axles

Please feel free to contact with us and send us the drawing.

We will quote the competitive price to you.

Welcome to visit our factory.