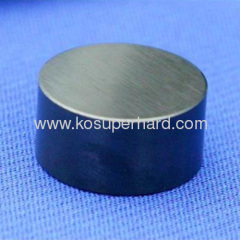

Solid PCBN inserts for rolls

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, D/P, D/A, T/T, Payapal, WU |

| Supply Ability: | 5000pcs/monthly |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | as request |

|---|---|

| Means of Transport: | Air |

| Product name: | Solid PCBN inserts for rolls |

| Material: | PCBN |

| Application: | machining ferrous metal |

| Feature: | Perfect hardness, good impact resistance |

| Usage: | Cutting, Grooving, Milling |

| Condition: | High temperature and high pressure |

| Samples: | Available |

| Certification: | ISO9001;2008 |

| Color: | Black |

| Quality: | High |

| Production Capacity: | 5000pcs/monthly |

| Packing: | as request |

| Delivery Date: | 7 to 15 days |

Product Description

susie @ moresuperhard.com

The Description of Solid CBN

Solid CBN inserts are completely made by CBN with no material joints, twice high temperature and high pressure during the manufactruing process to obtain the finished solid CBN inserts, firstly HBN powder is transformed to CBN powder, then CBN powder plus bond transformed to PCBN, so the finished solid CBN inserts have the best heat absorption capacity and can work at highest temperatures. Also solid CBN inserts have good chemical inertness to ferrous metals, so it has a wide machining application for turning atuomobile brake disk, grey cast iron, nodular cast iron, ductile cast iron, hardened steel etc. for rough machining to semi-finish machining.

The Features and Advantages of Solid CBN

1.With the advantages of high abrasive resistance, high processing precision, good thermal conductivity and long service life, the PCBN insert meets the international standard of ISO.

2.The PCBN insert can realize high speed cutting and hard material cutting with high work efficiency, and also can facilitate fast clamping.

3.Our PCBN insert can be used repeatedly, up to 50 times tool life of carbide with CBN turning inserts. Will lower your processing cost.

4.High material removal rates decrease operation cycle times, providing more parts per shift. Cutting speeds two to three times those of conventional tools.

5.Longer tool life resulting in excellent dimensional control and consistent surface finishes. Together these provide improved work piece quality and minimize scrap rates.

6.Increased machine tool uptime as a result of longer tool life provides greater production capacity without investment in new equipment.

7.PCBN inserts provide significant productivity and cost savings in manufacturing operations. The full potential and value of super abrasive tools over conventional tooling can be evaluated by tracking gains in productivity

The Application of Solid CBN

The PCBN insert is used to process hardened steel, hardened cast iron, grey cast iron and iron series metal work pieces.

The Specification of Solid CBN

| Insert Type | Size Info | ||||

L(mm) | I.C(mm) | S(mm) | R(mm) | D(mm) | ||

RNMN120400 | - | 12.700 | 4.76 | - | - | |

RNMN160700 | - | 15.875 | 7.94 | - | - | |

RNMN180700 | - | 18.000 | 7.94 | - | - | |

RNMN200800 | - | 20.000 | 8.00 | - | - | |

RNMN201000 | - | 20.000 | 10.00 | - | - | |

RNMN251000 | - | 25.400 | 10.00 | - | - | |

As a Solid PCBN inserts manufacturer and exporter in China,our PCBN inserts has excellent performance in processing gray cast iron,nodular cast iron,hardened steel and material,sintered metal,and processing work piece surface is highly polished and very durable. We can manufacture cylinder,cube,square ,diamond and triangle shape PCBN inserts products according to customers' requirements