Desulfurization belt for power plant

| Min. Order: | 50 Square Meter |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | Tiantai,Zhejiang,China |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Taizhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Polyester Filter Mesh, Filter Cloth, Nonwoven Needle Felt |

Product Detail

| Model No.: | HD004 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Style: | Plain |

| Pattern: | Plain Dyed |

| Width: | 57/58" |

| Material: | Polyester / Nylon |

| Use: | Industrial |

| Brand Name: | huading net |

| Density: | 22-23 yarn(cm) |

| usage: | dewatering for plaster |

| plaster efficiency: | less than10% |

| Production Capacity: | Tiantai,Zhejiang,China |

| Packing: | Bags;Wooden box;seaworthy package |

| Delivery Date: | 10 days after receive the payment |

Product Description

Technical parameter

type | monofilament Diameter(mm) | Density yarn(cm) |

|

| usage | ||

| |

|

|

>N/CM | L/㎡S | ||

HD004 | 0.28×0.50 | 0.5㎜ | 22 | 13 | 2128 | 375 | desulfurization and denitrification in power plant |

Where to use

Desulfurization and denitrication for power plant

Advantage

1. special section monofilament and multifilament wires. it can retain 2-20micron Material and high productiove efficience,the moisture content of filter cakes is very low, so the filter material is easy to peel off.

2.and high productive efficience. the moisture content of filter cakes is very low, so the filter material is easy to peel off.

3.high viscosity PET as raw material, so it have good abrasion resistance and strength filter belt is easy to reproducible

4.good steady property, while the belt bear tension strength in availiable temperature.

5.the usage of slipper joint,to make the fabric stable and long service time

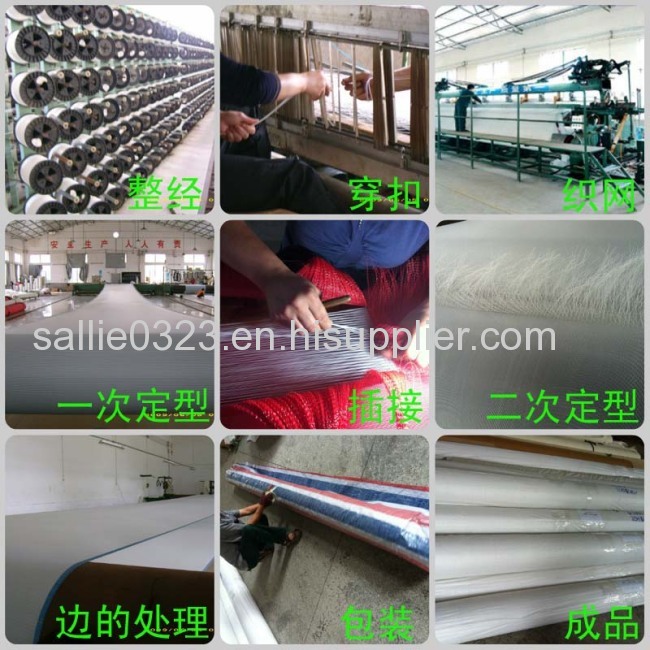

Processing

(warping--wear buckle--knit mesh--once heat setting—making slipper joint--twice heat Setting--edge treatment—package—finish)

Treatment

We make metal clipper joint for our sludge dewatering belt, it is easy to install in all kinds of belt filter press machine

We apply resin edge reinforcement for our belt, so the belt have good abrasion.

Conducting bar is adhere on the edge of fabrics, so the fabrics will not deviate the equipment.

We cover the cloth on the clipper joint of the fabrics, so the joint will not leakage mud because of the high permeability.

Quality control

Air permeability test apparatus according the standard of ASTMD737 and Breaking force test apparatus according the standard of D5035

.jpg)