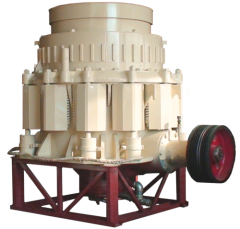

high quality iron crusher

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Wood Crusher, Metal Crusher, Plastic Crusher, Tire Crusher |

Product Detail

| Model No.: | XF-600 |

|---|---|

| Means of Transport: | Ocean |

| Type: | Utility |

| Style: | Others |

| Brand Name: | xinfei |

| Power(k w): | 37 |

| Capacity(t/h): | 300-700 |

| Cover(M2): | 7 |

| Size and shape(m): | 2.6*1.6*1.25 |

| Packing: | wooden |

| Delivery Date: | 5 days |

Product Description

Brief introduction of the iron crusher:

Iron crusher is also named steel scrap crusher or shredder.The iron crusher,beverage cans scrap crusher,crusher cans and metal pellet crusher are a new type of efficient,energy-saving, environmental protection, the new mill produced by Zhengzhou Xinfei Manufacturing Manufacturing Co. according to the urgent needs of the market,combined with the specific organizational strength and the actual application of domestic and foreign customers.The iron crusher,flexible and convenient ,has tight structure and large output notable features.

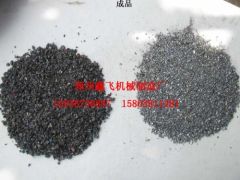

The scopes of the iron crusher:

The iron crusher is mainly used in the large waste recycling.It can crush scrap iron, broken metal, paint bucket, Wong Lo Kat, beer bottles and cans into ideal granules,reducing transport costs.Users can use a variety of configurations,depending on the type, size and processing raw materials and finished goods requirements.The iron crusher of Zhengzhou Xinfei professional manufacturer has been successfully used in Australia, South Africa, Russia and other scrap metal recycling companies and we achieve the praise of customers.

The structural features of the iron crusher:

The machine is mainly made of the worm gear motors,chassis,racks,helical cutter combination,driveshaft,the driven shaft,gear,pinion and other parts.Since the majority of required broken metal shavings are brittle,therefore chip breaker machine, pinion, iron sieve and other parts must be made of hard wear-resistant material sets magic.Flywheel mounted on the spindle so that the spindle has a large torque when broken off iron. In addition, the spindle is best to use a fluid coupling drive to eliminate excessive motor peak current and absorb the vibration of the spindle.When the machine is used to broke off pieces of high wear-resistant materials turnings like bearing iron, the rotor must also be coated welded to enhance its wear resistance.