14MT 8 in 6 Transistors out PLC with RS232 cable by Mit**subishi FX2N by GX Developer ladder With data cable(ARM)

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, paypal, WU |

| Supply Ability: | 100 |

| Place of Origin: | Shandong |

Company Profile

| Location: | Jinan, Shandong, China (Mainland) |

|---|---|

| Business Type: | Trading Company |

Product Detail

| Production Capacity: | 100 |

|---|---|

| Packing: | Box |

| Delivery Date: | 15-23days |

Product Description

Compatiable Fx2N series PLC

the power supply is DC24V

Support connecting HMI compatible with Mitsubishi PLC

Supports all text can be connected to Mitsubishi PLC connection

Supports two stepper motors connected

Supports encoder

Supports PC monitoring function

Unique encryption technology,can not decrypt after encrypted

Supports 32-bit

Direct download Without conversion

ARM version PLC Instruction(The old user must see)

1. Expanding internal resources,Achieving continuous address,Expanding resources(M0-M3071,S0-S999,T0-T255,C0-C255,D0-D999)

2. Before,Power off retentive paragraph are D512-D543,M512-M768,S512-S575,And incompatible with Japan's Mitsubishi .After adjusted ARM version,it's fully compatible with Japan's Mitsubishi, are D200-D500,M500-M1023,S500-S999.

3.High-speed output increased to 2-ways from original1-way,as same as Mitsubishi PLC,support X0-X7.Supports encoder such as C251 or C252,254.But not support C253 and C255.

4.Output drives are domestic before,we imported all output drives for the ARM version,and output current reaches 3A,Since Y0 and Y1 are High-speed output,Circuits are different,So it's only 1A output current for Y0 and Y1.

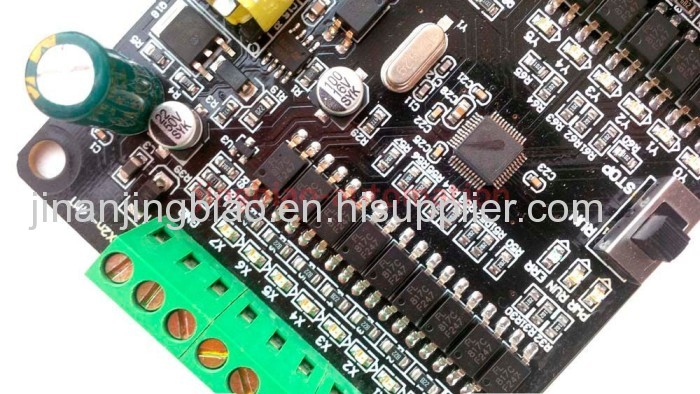

5.In order to distinguish old and new versions,using green PCB for old version and black PCB for new.

This board use industrial grade CPU,it is powerful, faster, more stable performance, special encryption make PLC that can not be cracked.

Ladder diagram computer programming is flexible and convenient for you, (note: it only serial RS232 ports, no RS485 interface), and human-computer interface (touch screen text display) supporting the use of Confidential performance is good, the inside of the programming function cannot be copied, protect your work achievement.

Don't need software conversion, direct download monitoring and normal PLC as download mode

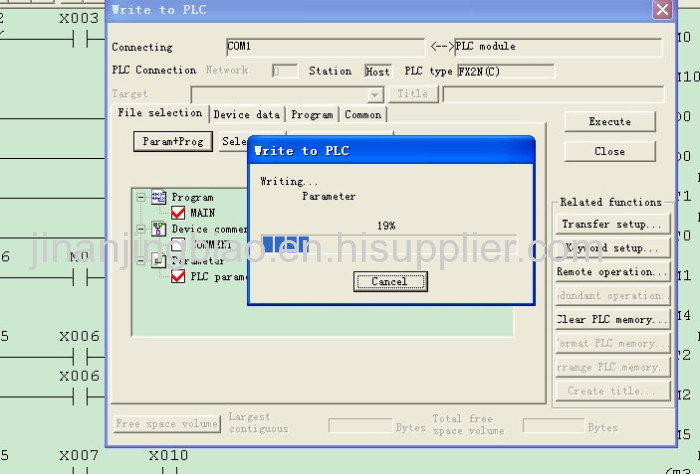

Can directly use mitsubishi programming software GX Developer or GX Works2 programming, download, debugging and monitoring.

Instruction descriptions:

Write Program, parameters, comments

Read Program, parameters, comments

Check Program, parameters, comments

Computer monitoring function (convenient debugging)

Soft element batch function

Soft element landing function

Soft element test function

Clear memory function

Connection text HMI function (baud rate 9600, data bit 7, parity bit, even parity check (even), stop bit 1)

Connection touch screen Display function (baud rate 9600, data bit 7, parity bit, even parity check (even), stop bit 1)

Data retention during power-down function

The product currently supports the following commands in Fx2N:

Basic instructions:

LD,LDI,AND,ANI,OR,ORI,INV,OUT (OUTT,OUTC),SET,RST,ANB,ORB,LDP,LDF,ANDP,ANDF,ORP,ORF,PLS,PLF,MPS,MRD,MPP,RET,NOP,END.

Step Instruction:

STL: support up to 8-way parallel branch.

Contact comparison instruction:

LD>=,LD<=,LD>,LD<,LD<>,LD=,AND>=,AND<=,AND>,AND<,AND<>,AND=,OR>=,OR<=,OR>,OR<,OR<>,OR=.

Send and compare instructions:

MOV,CML,XCH,BCD,BIN,CMP,ZCP,FMOV.

Four arithmetic instructions:

ADD,SUB,MUL,DIV,INC,DEC,WAND,WOR,WXOR,NEG.

Rotate instruction:

ROR,ROL,RCR,RCL.

Data processing instruction:

ZRST,DECO,ENCO,SUM,BON,MEAN.

program flow command:

CJ (maximum 16 address) CALL (a maximum of five nesting, 16 sub-programs), SRET, behind FEND, the WDT FOR (a maximum of five nested) NEXT.

Convenient command:

ALT.

High-speed processing instruction:

PWM (support Y0, Y1, all the way, can be used simultaneously), SPD (only supports X0 and all the way) PLSY (only support Y0 way, 20K-200Hz)

Peripherals, I / O ports:

SEGD.

Peripherals SER command:

ASCI.

nibble exchange command:

SWAP.

Note: instruction LDP + LDF + PLS + PLF + MOVP + DMOVP not more than 64

Currently supports the following resources

Soft components:

X0-X27, Y0-Y27,

Special software components:

M8000 (operation monitoring contactor), M8001 (operation monitoring back contactor).

M8002 (initialization pulse contactor), M8003 (initialization pulse reverse contactor)

M8004 (error

indication contactor).

M8011 (10 milliseconds clock pulse), M8012 (100 milliseconds clock pulse), M8013 (1 seconds the clock pulse), M8014 (1 time sharing the clock pulse).

M8020 (zero mark), M8021 (borrow mark), M8022 (carry flag).

M8029 (instruction execution end mark).

M8033 (memory keep contactor).

M8034 (banned output contactor).

M8200 - M8203 (C200 - C203 count direction).

M8235 (C235 count direction).

D8000 (monitoring timer setting).

D8012 (maximum scanning time).

D8140, D8141 (Y0 pulse output count register)

Constant scope of support:

16-bit operation. K range: -32768 to +32767 or 0 to 65535; H range: 0 to FFFFH.

32-digit operating. K: - 2147483648, 2147483647 or 4294967295; the H range the: 0 ~~ FFFFFFFFH.

Maximum memory capacity: 8,000 steps.