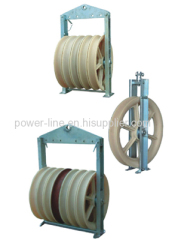

Overhead line transmission pulley block for stringing 26-31mm conductors

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1000 sets per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | SHWQN660x100 |

|---|---|

| Means of Transport: | Ocean, Land |

| Stringing blocks Sheaves: | 1,3,5,7 |

| Pulley block Outer Diameter: | 660mm |

| Cable block Inner Diameter: | 560mm |

| Conductor Pulley Width: | 100mm |

| The Biggest Applicable Conductor: | LGJ500 |

| Stringing roller diameter: | 660X560X100mm |

| Stringing block Material: | Nylon/Aluminum/Steel |

| Production Capacity: | 1000 sets per month |

| Packing: | According to customers' requirments |

| Delivery Date: | 30 days |

Product Description

Overhead line transmission pulley block for stringing 26-31mm conductors

1.660mm overhead line transmission stringing block

2.Numbers of Sheaves:1,3,5,7

3.The sheave size: Φ660 x560x100

We can supply a complete range of these stringing blocks for single conductor, 2 bundled conductors and 4 bundled conductors stringing.

tem No. | Model | Quantity of sheaves | Working Load (KN) | Weight (kg) | Material of sheaves |

10121 | SHD660x100 | 1 | 20 | 30 | Aluminum |

10122 | SHS660x100 | 3 | 40 | 106 | Central:steel Sides:aluminum |

10123 | SHW660x100 | 5 | 60 | 150 | |

10124 | SHDN660x100 | 1 | 20 | 24 | MC nylon |

10125 | SHSLN660x100 | 3 | 40 | 92 | Central:steel Sides:aluminum |

10126 | SHWLN660x100 | 5 | 60 | 120 | |

10127 | SHSQN660x100 | 3 | 40 | 76 | MC nylon |

10128 | SHWQN660x100 | 5 | 60 | 110 | |

10129 | SHQZ660x100 | 7 | 80 | 268 | Central:steel Sides:aluminum |

10130 | SHQ660Ax100 | 7 | 75 | 190 | Central:steel Sides:MC nylon |

Application:Stringing blocks are used to support the conductors on transmission line during stringing operation and sagging operation.

Nylon sheave blocks are are best sellers in stringing blocks.

The advantages of Nylon sheave blocks:

1.Light

2.Wear resistant

3.Lower price

4.Nylon can effectively reduce the damage to conductors when stringing

5.Long lifespan.

Why we should use conductor stringing blocks?

In the age of electric and information, conductor line transmission becomes more and more necessary. Conductor stringing blocks can make line stringing more flexible and easily with its pulley wheels.

What characteristics should be included to be qualified stringing blocks?

1. The design,manufacture and testing should be in compliance with the industry standard.

2. The safty factor should ≥3

3. The stringing block should be easy for maintenance

4. The Friction coefficient should ≤1.015

5. The stringing block can pass throuhj the running board, Connecting tube protector and rotary connectors smoothly.

6. The steel wire sheave should be designed to reduce the damage to pilot stringing wire.

7. The surface of the block should be smooth, no sharp corners, no sharp edges. There should be no parts trachoma, pores, cracks and porosity and other defects. Welds should be nice and smooth, no burrs, no cracks, no folding, no overheating or burning defetcs to lower the intensity

8. The frame structure should be reasonable and firm,its strength and rigidity should be in accordance with the requirements. It should be made of high-strength materials to reduce the overall weight of the multiple sheaves block.The joints should be set with safe stop device, and ease of disassembly. A reasonable ceiling hanging ring is necessary too.