Calcium Silicon Cored Wire Refractory Powder Metallurgy use for Blast Furnace

| Min. Order: | 15 Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 1000 Ton/Tons per Month |

| Place of Origin: | Henan |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | CSCW09 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand Name: | HC |

| Mesh Size: | 13mm:255g/m;16mm:330g/m |

| Diameter: | Φ 13 mm (255 g/m), Φ 16 mm (330 g/m) |

| Material: | Si Ca Al C P S |

| Chemical Composition: | casi30 |

| Application: | steel making, deoxidizer,inoculant and alterant |

| Carbon Content: | Medium Carbon |

| unit price: | Get Latest Price |

| Shape: | coil |

| Model Number: | Ca31Si60 ,Ca28Si60 |

| colour: | silvery |

| packaging: | According to agreement. |

| Production Capacity: | 1000 Ton/Tons per Month |

| Packing: | 1MT per big bag |

| Delivery Date: | 20 days after receiving advance payment |

Product Description

Product feature:

Adjusting steel ingredients accurately.

Improving alloy receiving.

Avoiding gas into steel liquids.

Calcium Silicon Cored Wire Refractory Powder Metallurgy use for Blast Furnace

To let steel liquid react stably, and make it more purity.

Strong adaptability and wide applications.

Convenient operation and maintaining environment without pollution.

Features

· Being propitious to adjust and control the active metal and the content of microelement.

· Keep stable of the alloy performance function, reducing steelmaking cost.

· Changing the inclusion form to improve the mechanical property.

· Facilitate the operation and reduce the operation cost.

Calcium Silicon Cored Wire Refractory Powder Metallurgy use for Blast Furnace

Description

Calcium Silicon Cored Wire Refractory Powder Metallurgy use for Blast Furnace is a new treatment in secondary steelmaking developed in recent years, alloy core wire can purify the molten steel, change the inclusion form, improve the cast ability of the importantly, it will increase the yield of alloy ,cut down the cost and consumption.

casi cored wire Steelmaking auxiliary from China factory manufacturer use for electric arc furnace mainly used in outside furnace refining process and taking place of ferroalloy. Alloy cored wire is more advantageous compared with use of powder spraying method and putting ferroalloy directly in ladle refinery.Cored wire technology can adjust steel ingredients accurately,improve alloy receiving,avoid gas into steel liquids,let steel liquid react stably, and make it more purity,strong adaptability and wide applications,convenient operation and maintaining environment without pollution.Cored wire injection is also integrated in the foundry practice of desulphurization, inoculation and nodularization process, with significant quality improvement.Our company is very popular for her good performance of product and favorable service.

•Application Mainly used in steelmaking in electric arc furnace, screening water, Additives of Metallurgy,producing carbon materials.

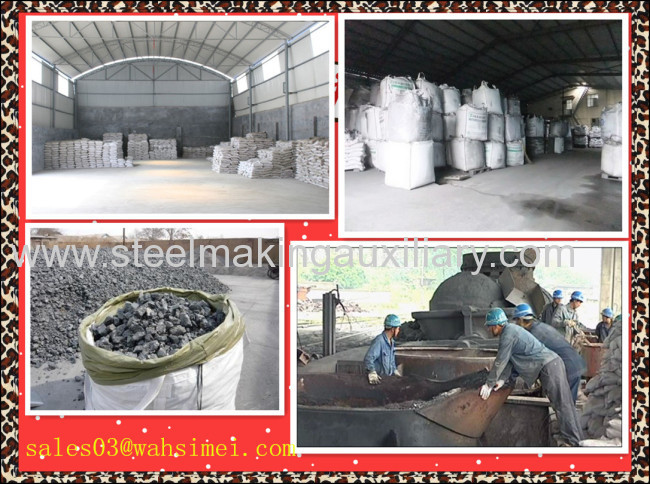

About Factory

•Experience More than 11 years experience in producing Steelmaking materials and 3 years in exporting. Our factory has been certified by ISO 9001 quality management system and granted with coal management qualification certificate(JAF) and the right for raw materials export.

•Service we can supply the Steelmaking auxiliary with any knids of products with good quality.Owning a large-scale production equipment, engaging in R&D, manufacture and trading. With the most excellent work team, most advanced equipment and strict quality systems

•Market Our products are marketable in domestic and overseas.The large steel enterprise such as Nucor Corporation (USA), NLMK (Russia),JSW Steel (India), Xuelun(China), And we almost monopolize India's market.

Calcium Silicon Cored Wire Refractory Powder Metallurgy use for Blast Furnace