High Performance API Oval Metal Pipe Flange Ring Joint Gasket of Rilson Soft iron (RS2-R,RX,BX)

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100000 pcs /month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | RS2-B,BX,RX |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Standard or Nonstandard: | Standard |

| Style: | O Ring |

| Material: | Metal |

| Brand Name: | Rilson |

| Material: | ss304, 316L, carbon steel, etc. |

| Standard: | ASME, DIN, etc |

| Production Capacity: | 100000 pcs /month |

| Packing: | wooden cases, plastic film |

| Delivery Date: | 15-60 days |

Product Description

Material

The gasket material should be selected to suit the service conditions. It is always recommended that the gasket material be softer than the mating flanges. The more popular Ring Type Joint materials, with the recommended maximum hardness and identification as specified in API 6A, are shown in the table below. For more highly specialized applications, Ring Type Joints can be machined from DUPLEX steels and other exotic materials such as Monel®, Inconel®, Incoloy®, and Hastelloy®. The Technical Department is available to advise on other materials.

MAXIMUM HARDNESS | ||||

MATERIAL | UNS NUMBER | BRINELL | ROCKWELL B† | IDENTIFICATION |

Soft Iron | 90 | 56 | D | |

Low Carbon Steel | 120 | 68 | S | |

4–6% Chrome 1/2% Moly | K42544 | 130 | 72 | F5 |

Type 304 Stainless Steel | S30400 | 160 | 83 | S304 |

Type 316 Stainless Steel | S31600 | 160 | 83 | S316 |

Type 347 Stainless Steel | S34700 | 160 | 83 | S347 |

Type 410 Stainless Steel | S41000 | 170 | 86 | S410 |

Titanium Grade 2 | R50400 | |||

Alloy 600 | N06600 | 200 | ||

Alloy 625 | N06625 | 200 | ||

Alloy 800 | N08800 | 200 | ||

Alloy 825 | N08825 | 160 | ||

Hastelloy | N10001 | 200 | ||

Alloy C276 | N10276 | 200 | ||

SMO 254 | S32154 | 180 | ||

Zeron 100 | 200 | |||

Super Duplex | S31803 | |||

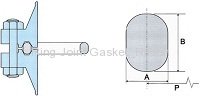

STYLE R | |

| The Ring Type Joint was initially developed for high pressure/temperature applications found in the petroleum industry and is primarily used in the oil field on drilling and completion equipment. However, today this product range can also be found on valves and pipework assemblies, along with some high integrity pressure vessel joints. Standard Style R Ring Type Joints are manufactured in accordance with both API 6A and ASME B16.20 size/ratings. Available in both oval and octagonal configurations, both types are interchangeable on the modern octagonal type grooved flanges. |  |

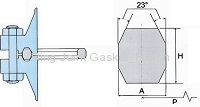

DIMENSIONAL DATA – STYLE R

| Oval | TOLERANCES: (INCHES) A (width of ring) ±0.008 B, H (height of ring) ±0.020 P (average pitch diameter of ring) ±0.007 23° (angle) ±1/2° |

| |

Octagonal | Rilson Style R Ring Type Joints can be manufactured in accordance with all relevant standards to suit the following flange designations: API 6A ASME/ANSI B16.5 MSS SP44 (ASME B16.47 SERIES A) BS 1560 |

|

STYLE RX | |

| The Style RX is an adaptation of the standard Style R which energizes on assembly. The RX is designed to fit the same groove design as a standard Style R, making the joints interchangeable. Consideration should be given to the difference in finished make-up distance. The modified design uses an energizing on assembly effect which improves the efficiency of the seal. |  |

DIMENSIONAL DATA – STYLE RX

| TOLERANCES: (INCHES) *A (width of ring) +0.008,-0.000 H (height of ring) +0.008,-0.000 OD (od of ring) +0.020,-0.000 23° (angle) ± 1/2° |

*A plus tolerance of 0.008 inches for width |

STYLE BX | |

| The Style BX energized Ring Type Joints, manufactured in accordance with API 6A, are designed for use on pressurized systems up to 20,000 psi. When correctly fitted, the style BX gasket allows virtual face to face contact of the flange faces which means that the gasket is fully trapped on both the inner and outer diameters. All BX gaskets incorporate a pressure balance hole to ensure equalization of pressure which may be trapped in the grooves. |  |

DIMENSIONAL DATA – STYLE BX

| TOLERANCES: (INCHES) *A (width of ring) +0.008,-0.000 D (hole size) ± 0.02 H (height of ring) +0.008,-0.000 OD (od of ring) +0.000,-0.005 23° (angle) ± 1/4° |

One pressure passage hole required per ring |

More surprise at sales02@rilson.com.cn

If you are interested in my products, please kindly send me an email and I will reply to you as soon as possible.

Your success is my business.