2014 ASME B16.20 or B16.47 Spiral Wound Gasket ss304/316L Graphite (RS1)

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100000 pcs /month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | RS1 |

|---|---|

| Means of Transport: | Ocean, Land |

| Material: | ss304, 316L, carbon steel, graphite, PTFE, etc. |

| Production Capacity: | 100000 pcs /month |

| Packing: | wooden cases, plastic clips |

| Delivery Date: | 15-60 days |

Product Description

The concept of spiral wound gasket construction was originated by Flexitallic in 1912, inaugurating the beginning of a new era in safe, effective sealing. And we are the main supplier of spiral wound gasket in China. The primary purpose for this development was the increasingly severe temperatures and pressures used by U.S. refinery operators in the first half of the century. The necessity for a gasket to have the ability to recover cannot be over emphasized. The effects of pressure and temperature fluctuations, the temperature differential across the flange face, together with bolt stress relaxation and creep, demand a gasket with adequate flexibility and recovery to maintain a seal even under these varying service conditions. The Rilson Spiral Wound Gasket is the precision engineered solution to such problems, meeting the most exacting conditions of both temperature and pressure in flanged joints and similar assemblies and against virtually every known corrosive and toxic media.

| Available Gasket Material | ||

METAL WINDING STRIP AS STANDARD Stainless Steel type 304 316L OTHERS Stainless Steel type 304L 309 310 316Ti 317L 321 347 430 17-7PH ALLOY 20 MONEL® TITANIUM® NICKEL® 200 INCONEL® type 600 625 X-750 HASTELLOY® type B-2 B-3 C276 INCOLOY® type 800 825 DUPLEX ZIRCONIUM® TANTALUM® COPPER PHOS-BRONZE | FILLER MATERIAL Flexicarb® flexible graphite Thermiculite® 835 Flexite Super® PTFE Mica Ceramic Non-sintered PTFE Thermiculite®, Rilson'S proprietary high-temperature, sealing material is comprised of chemically exfoliated and thermally exfoliated vermiculite. This revolutionary patented product simulates the structure of exfoliated graphite but with one notable exception … gaskets made with Thermiculite® maintain their integrity, even at extreme temperatures. Thermiculite is thermally stable, ensuring against thermal oxidation, at temperatures in excess of 1800ºF (Thermiculite® 835). | GUIDE RING MATERIAL AS STANDARD Carbon Steel OTHERS Stainless Steel type 304 304L 316 316L 316Ti 310 321 347 410 INCONEL® 600 625 MONEL® TITANIUM® NICKEL INCOLOY® type 800 825 ALLOY 20 HASTELLOY® type B-2 B-3 C276 |

NOTES:

Selected materials should be compatible with operating temperature and chemicals. If in doubt, contact Rilson Technical Department.

If PTFE is subjected to temperatures above 250°C (500°F) decomposition starts to occur slowly, increasing

rapidly above 400°C (750°F). Care should be taken to avoid inhaling the resultant fumes, which may produce hazardous effects

Gasket Select

|  |  |  |

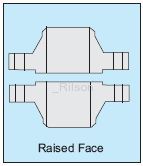

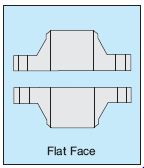

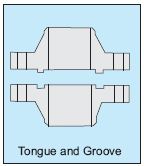

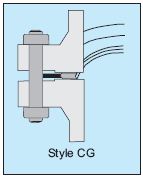

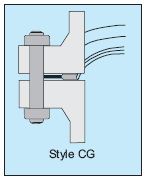

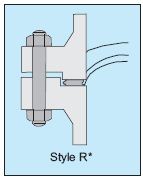

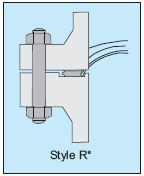

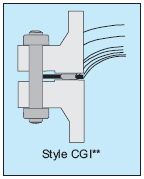

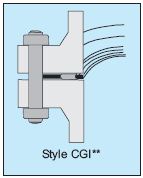

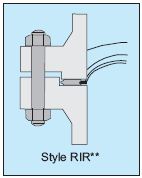

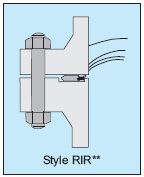

RS1-CG - Utilizes an external ring which accurately centers gasket on flange face, provides additional radial strength to prevent gasket blow-out and acts as a compression stop. A general purpose gasket suitable for use with flat face and raised face flanges up to and inclusive of class 2500. See note at bottom of page 8 for inner ring requirements. | RS1-CGI - A Style CG gasket fitted with internal ring which gives an additional compression limiting stop and provides heat and corrosion barrier protecting gasket windings and preventing flange erosion. Suitable for use with flat face and raised face flanges. See note at bottom of page 8 for inner ring requirements. | RS1-R - Basic construction type. Inner and outer diameters are reinforced with several plies of metal without filler to give greater stability and better compression and sealing characteristics. Suitable for tongue and groove or male and female or grooved to flat face flange assemblies. | RS1-RIR - Solid inner metal ring acts as a compression stop and fills the annular space between flange bore and the inside diameter of the gasket. Designed to prevent accumulation of solids, reduce turbulent flow of process fluids and minimize erosion at flange faces. Suitable for male and female pipe flanges. |

STYLE CG & CGI GASKETS TO SUIT STANDARD RAISED FACE AND FLAT FACE FLANGES

Selection Guide

|  |  |  |  |

|  |  |  |  |

|  |  |  |  |

WHEN ORDERING PLEASE SPECIFY | EXAMPLE |

GASKET STYLE | FLEXITALLIC STYLE "CGI" SPIRAL WOUND GASKET |

NOMINAL PIPE SIZE (NPS) | 4" |

PRESSURE RATING | CLASS 900 |

GASKET STANDARD | ASME B16.20 |

WINDING MATERIALS | 316L/FLEXICARB (FG) |

OUTER RING MATERIAL | CARBON STEEL |

INNER RING MATERIAL | 316L |

Note: Please select correct gasket style for your particular application.

Rilson RS1-CGI Gaskets with spiral wound outer ring are primarily designed for the male and female flanges and are custom built to suit the design conditions of individual heat exchanger vessels.

These gaskets are available in an extensive range of materials. This style incorporates several special features, as follows:

1. The outer wound nose to ensure correct sealing element location in the flange recess.

2. A spiral wound sealing element to ensure a positive seal under fluctuating temperature and pressure conditions.

3. A solid metal inner ring to protect the sealing element and act as a compression stop. As an optional extra, inner rings can also be supplied with nylon location screws to secure the gasket to the flange on assembly.

4. Can be supplied with pass partition bars in any configuration. Pass bars are secured to the inner ring and can be supplied in either solid metal or double jacketed construction.

Recommended Gasket Style

For high pressure/temperature duty, also for gaskets with PTFE filler, corrosive or fluctuating pressure or temperature service conditions.

More interest at sales02@rilson.com.cn.

If you are interested in my products, please kindly send me an email and I will reply to you as soon as possible.

Your success is my business.