Lab test powder coating curing oven colo-4355-T With CL660-T-H

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | EXW |

| Payment Terms: | L/C, PayPal, T/T, WU |

| Supply Ability: | 100 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean, Air, Land, Air courier |

|---|---|

| Power: | Others |

| Raw Material: | Others |

| Machine Type: | Others |

| Extra Services: | Painting / Powder Coating |

| Automation: | Manual |

| Certification: | CE |

| Material / Metal Processed: | Aluminum |

| Brand Name: | COLO |

| voltage: | 110V/220V |

| Powder supply: | Electric |

| Categories: | electric powder coating oven |

| Powder: | 600W |

| Temperature: | RT+10~250°C |

| Inner size(mm)W*D*H: | 260*260*260 |

| Outside size: | 370×390×545 |

| Plate: | 2 pieces |

| Production Capacity: | 100 |

| Packing: | wooden box |

| Delivery Date: | 20 days |

Product Description

Lab test powder coating curing oven colo-4355-T

Features:

1. High-precision micro-computer temperature controller, temperature control accurate and reliable.

2. Warming up fast ( it can rise to 180 degrees in 15 mins.)forced convection,dry hot air directly

through the heated objects, drying, sterilization time significantly shortened.

3. Exceeds the limit is automatically interrupted, ensure personnel and safety.

4. Damper adjustment, timing control, shelf mobile box cleaning, always find it convenient to operate.

Technical Data

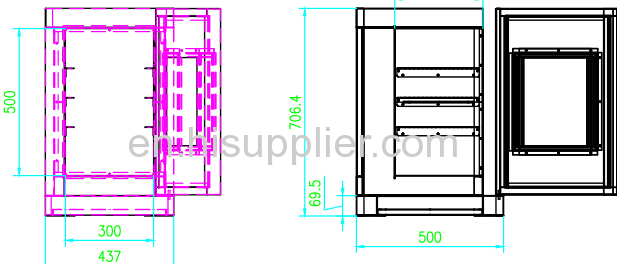

| Inner Size | L450mm*W500mm*H350mm | |

| Material: | t1.2mm galvanized plate | |

| Thickness Insulation: | 150mm | |

| Power supply: | ELECTRIC | |

| Voltage: | ||

| Frequency: | 50-60Hz | |

| Door type: | ONE SIDE | |

| Warm-up time: | 15 min. (180-220° C) | |

| Homogeneity: | < ± 3°C if 185°C | |

| Temperature stability: | < ± 1°C | |

| Transport: | Top | |

| Air circulation: | Forced | |

| Total power of burner | 3KW | |

| Warranty: | 12 Months | |

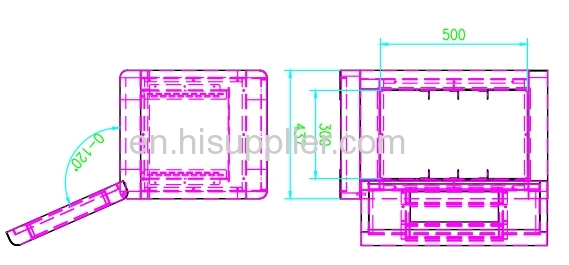

Colo-660 Pulse manual powder coating system

COLO-660 series features:

It has pulse and one-touch intelligent function, and is good for flat parts, complex parts, recoat parts and conner.

Flat model: maximizes voltage for superior transfer efficiency with coating flats parts.

Complex model: adjust the voltage while holding current when coating complicated shapes and corners.

Recoat model: adjust the voltage and current automatically for recoating of parts.

Pulse model: rapidly recharges the powder to coat complex shapes.

Technical Data

| Master | |

| Power range | 100- 240v(220V) |

| Frequency | 50/60HZ |

| Rated output voltage | 24VDC |

| Input voltage | - 200kv |

| Temperature range in use | -10 ºC+50 ºC |

| Air pressure | |

| Maximum input-air pressure | 10kg/cm3 |

| Minimum input-air pressure | 6kg/cm3 |

| Maximum water vapor content or compressed air | 1.4g/ m3 |

| Maximum compressed-air consumption | 13.2 m3/h |

| Powder Gun | |

| Gun weight: | 500G |

| Maximum output voltage | 0-100KV ( adjustable) |

| Maximum output current | 180Ua(max) |

| Maximum powder injection | 600g/min |

| Polarity | negative (-) |

COLO have been working in the powder coating industry for over 10 years. we manufacture powder

coating machinery products are the culmination of

the knowledge and expeience we have gained

over the many years we have been working with our customers in the powder coating industry.

Any question,pls contact sonne