Infrared powder coating gas industrial heater

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | Paypal, T/T, WU |

| Supply Ability: | 500 sets/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

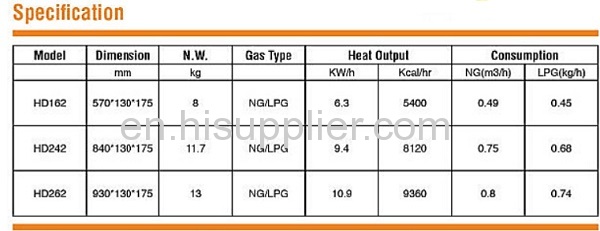

| Model No.: | HD262 |

|---|---|

| Means of Transport: | Ocean, Air |

| Model: | HD262 |

| Brand: | COLO |

| Voltage: | 110/220V |

| Application: | powder coating oven |

| Certificate: | CE |

| Warranty: | 12 months |

| Place or original: | Hangzhou |

| Production Capacity: | 500 sets/month |

| Packing: | Carton box |

| Delivery Date: | within 7 days after payment |

Product Description

Infrared powder coating gas industrial heater

Infrared gas heater Details:

Why do you choose Catalytic infrared heaters???

reasons:

· Saving 20%~30% energy than common gas burner.

· Friendly to environment.

· Long useful time: ≥11000hr

· Completed thermostat controlling system

Working principles of industrial oven gas burner infrared HD162 :

Infrared catalytic heater uses the porous cordierite honeycomb combustion plate with a special

catalyst coated as a core component .

Its catalytic combustion is the best combustion mode ,which means that gas (natural gas, liquefied

petroleum gas) and combustion-supporting gas (air) are mixed according to the scientific proportion

through burner shell (pre-mixed room) with the precise design and manufacturing .

Ignited by the ignition, the gas mixture is burning on surface of catalyst which lies in the holes of porous cordierite honeycomb plate .

The vast majority(95%) of the heat generated in the form of infrared radiation penetrate the object

directly,put an end to energy loss caused by heating the air to heat the object, the mode of heat

convection heating , greatly improve the energy conversion ability so as to further save the energy

(save 60% of the operation costs under the same industrial conditions compared to the ordinary

heating mode --electric heating ).

Gas is almost under complete combustion as a result of catalytic ombustio. the flue gas pollution is

extremely low (CO<0.02%, NOX<10ppm) ,fully meeting the national environmental standards and

there is no need for direct exhaust fan.

COLO have been working in the powder coating industry for over 10 years. we manufacture powder coating machinery products are the culmination of the knowledge and expeience we have gained over the many years we have been working with our customers in the powder coating industry.

any question ,pls contact