Powder Feed Center or Powder Recovery System

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | EXW |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 200 sets/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | colo-6000pc |

|---|---|

| Means of Transport: | Ocean |

| Brand: | COLO |

| Type: | powder recover system, sieving machine |

| Coating: | Powder Coating |

| Voltage: | 380V/220V |

| Model: | COLO-6000PC |

| Powder pump: | 16pcs |

| Power: | 500W |

| Air pressure: | 0.6-0.8MP |

| Certification: | CE |

| Warranty: | 1 year |

| Production Capacity: | 200 sets/month |

| Packing: | wooden box |

| Delivery Date: | 20 days after payment |

Product Description

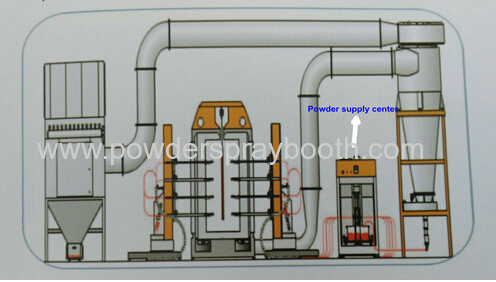

Powder Feed Center or Powder Recovery System

1.easy for color change ,don't need to clean the gun one by one

2.have sensor for powder position,don't worry about the powder is empty

3.could use the powder box directly.

Powder supply center

Automatic vibrating powder feed center parameters

Power supply voltage | 1P 220VAC (110V) |

Power | 500W |

Gas pressure | 0.6-0.8MP |

powder pump | 16pcs(max) |

How does the powder feed center work?

Put the powder hopper full with powder in the powder supply room, and on the powder hopper vibration platform,

and then access the air for the fluidization of powder. Vibration platform will vibrate at intervals.

Powder particles generated in the process of fluidization goes through the rear ventilation pipe so that powder doesn't spill.

In the process of powder gun working, the powder pump station will be decreased, so that the suction tube is inserted into fluidizing powder.

Control the pump station decreasing by powder detecting sensor, so that the powder suction tube keep been inserted into the sufficient fluidization powders.

With powder level declining, when the powder level reaches the lower limit, the powder center of the electronic control system

will issue audible alarm and on the touch screen with character note. Remind the operator low powder level alarm, and he or she needs to add powder.

In the cleaning process, lower the pump platform down to the powder cleaning level. Open and clear the powder. Powder center automatically blowbacks the

powder gun hoses of both sides alternately.

If change the color, rise the pump station to higher point for the powder hopper can be easily removed, and then carried the powder hopper with required color in.

More details,please contact with us.