Automatic Powder paintng plant system

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 1set per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Power: | Others |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Pipe and Tube Bending Machine |

| Extra Services: | Painting / Powder Coating |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Aluminum |

| Brand Name: | COLO |

| package: | wooden case |

| Size: | can be ordered |

| electric: | 220v/110v/380V 3phases |

| heating type: | LPS/GAS |

| Power supply: | electric |

| Frequency: | 50-60hz |

| Transportation time: | 60work days |

| Temperature max.: | 250°C |

| Production Capacity: | 1set per month |

| Packing: | nude packing |

| Delivery Date: | 60days |

Product Description

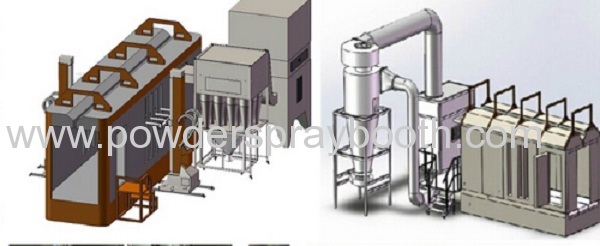

automatic powder coating production line

Working Process of automatic Powder Coating Line

1. Spraying pretreatment → 2. Drying oven → 3. Workpieces into spray booth→ 4. After

spraying the workpieces will go into the curing oven(20~25min, 180~200ºC)→ 5. Go out of

the oven,and natural cooling→ 6. Unloading workpieces

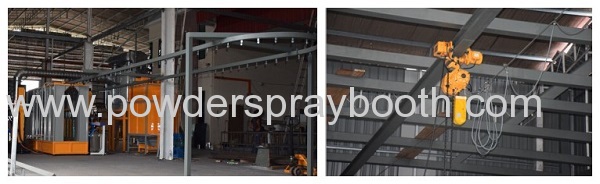

In our Malaysia Customer Factory

the size and design can be ordered by the clients requirements

1. Spraying pretreatment:

Using spray pretreatment methods, dirt, oils and contaminants are removed from the

product's surface and phosphate or conversion coatings are applied to help prevent corrosion

and increase paint adhesion

this part,you can choose by your actual work piece.

2. Drying oven

3.powder coating spraying booth system

1) It enables an automated cleaning procedure and consequently a quick color change.

2) Closed powder circuit - no powder escaping during coating or cleaning procedure.

This prevents powder loss, and the workplace and the environment remain clean

3) level sensor optionally available.

4) takes place by the touch-sensitive operating panel of the control unit.

4.Curing oven heating ( heating energy ) selection

1. Gas hot air heating system ( full automatic ) ---- Which is preferred by box curing oven.

Powder coating line continuous operation can also be selected ( Box furnace or powder

coating line curing tunnel should choose gas system

2. Fuel hot air heating system ( full automatic ) ---- As oil prices rise, higher operating costs

3. Far-infrared radiation heating system ( full automatic ) --- Running costs are high, but the

equipment investment is the most economical, especially small quantities spraying may be

considered.

5.overhead conveyor system and conveyor systems ;

6.other machines:automatic gun with the reciprocator powder sieve,powder feed

center,etc

We supply automatic, semi-automatic, manual and special type coating and painting lines

Powder coating lines for aluminum profiles ,metal powder coating plant consists

of pretreatment, powder coating, drying oven and curing oven, conveyor system and

electric control system.

It will help user expand output, form mass production and reduce cost in order to make

products' price more competitive.

Meet your needs is our goal to provide you with high quality products, satisfactory service is our

responsibility and our commitment

If you need a powder coating line quotation. we need some detailes more such as:

1) How big your factory? length, width, and hight?

2) What is size of your biggest workpiece, length and width, and weight??

3) Which energy do you want to use for heating oven? electric, gas or LPG?

4) The most imporant what's the production you prefer to realize after using new line?? (8hours)

5) How many color you need change every day? (8 hours)

6) Do you also need the pretratement systems, manual or automatic?

contact with sonne

.jpg)