Vertical Aluminum profiles powder coating line systems

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 2set per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean, Land |

|---|---|

| Brand Name: | HICOLO |

| Heating way: | Gas/oil/electic |

| Burner brand: | Riello Italia, dependent |

| powder spray booth type: | manual/automatic |

| manual powder coating gun qty: | 2 pcs |

| deliver time: | 60work days |

| Appication: | manual powder coating line |

| Voltage: | 220v/110v/380V 3phases |

| package: | wooden case |

| shippment: | sea |

| Production Capacity: | 2set per month |

| Packing: | not assembled |

| Delivery Date: | 60days |

Product Description

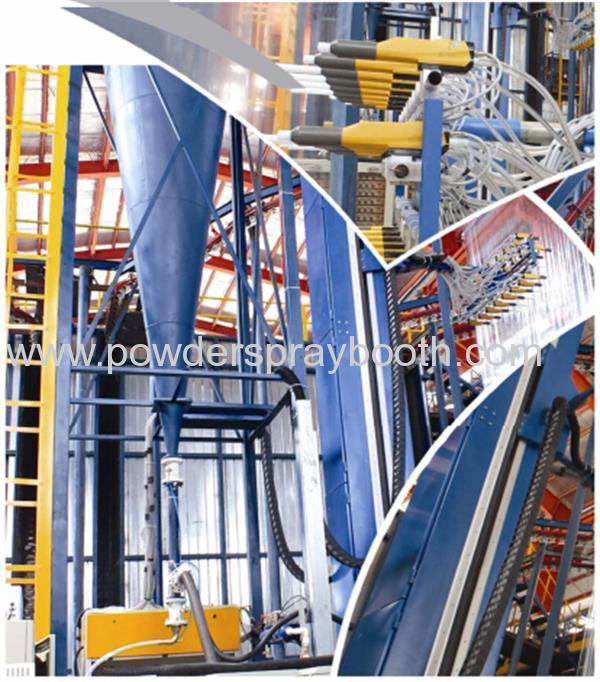

Vertical Aluminum profiles powder coating line/systems/finishing solutions

1.the conveyor,save the space,huge capacity,the height should be 14m;

2.The line for Aluminum profiles can reach to 40-60 tons per working hours,considering the weight of 4kg

for a profile of a 6m along;

3.The conveyor speed can be adjusted to 3m/min

4.The normal vertical powder coating :48guns in the two sides of the booth

The size of the line can be ordered according to the different work piece.

the process of the line :six parts

1.Multi-stage Spray pretreatment System is engineered to prepare a product's

surface for painting. Using spray pretreatment methods, dirt, oils and

contaminants are removed from the product's surface and phosphate

or conversion coatings are applied to help prevent corrosion and increase

paint adhesion.

2.Drying oven: which drying the water after pretreatment is designed according to

customer actual conditions. The temperature need is around 120-130 degrees.

3.Automatic powder coating booth (Plastic or Steel available) with big cyclone

and secondary filter system , reciprocator , Sieving system .

4.Automatic powder Coating Guns and Manual Powder Coating Guns

(For repair coating). All the guns are researched and produced by our

company and have very good quality.

5.Curing oven: Tunnel curing oven, bridge type curing oven.

the burner

6.Conveying system: Closed-circuit conveyor and power and free conveyor and so on.

Question:

How big your factory? length, width, and height??

How long about your aluminum profiles?

Which energy do you want to use for heating oven?? electric, gas or LPG??

The most important what's the production you prefer to realize after using new line?? (8hours)

how many color you need change every day?? (8 hours)