Double-side Manual Powder Coating Spray Booth

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | EXW |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 20 sets/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | CL-4213 |

|---|---|

| Means of Transport: | Ocean |

| Model: | COLO-4213 |

| Booth type: | Drive-thru |

| Operator dimensions: | 600width*1800height*4000depth |

| Overall dimensions: | 1300width*2600height*4000depth |

| Weight: | 1000kg |

| Power supply: | Electric |

| Normal power: | 12KW |

| Voltage: | 380V |

| Frequency: | 50~60HZ |

| Filters: | Polyester |

| Production Capacity: | 20 sets/month |

| Packing: | Wooden case |

| Delivery Date: | 25 days after payment |

Product Description

Powder Coating Spray Booth for Powder Coating Line

Specifications of the powder spray booth

Model | COLO-S-4213 |

Booth type | Drive-thru |

Operator dimensions | 600width* 1800height*4000depth |

Overall dimensions | 1300width* 2600height*4000depth |

Weight | 1000kgs |

Power supply | Electric |

Nominal power | 12KW |

Voltage | 380V |

Frequency | 50~60HZ |

Filters | Polyester |

Filters count | 6pcs |

Filters hang type | Easy to change |

Filter cleaning system | Pneumatic |

Warranty | 12 months |

Benefits of our Powder Booths

1,Multi-Cyclone recovery system ensures extremely high levels of powder recovery 98% .

2,Faster Color Change:The Bottom of the Booth prevents accumulation of the powder and makes it very easy for cleaning and quick Color change.

3,Higher life of cartridge filter with unique Rotary wing cleaning mechanism

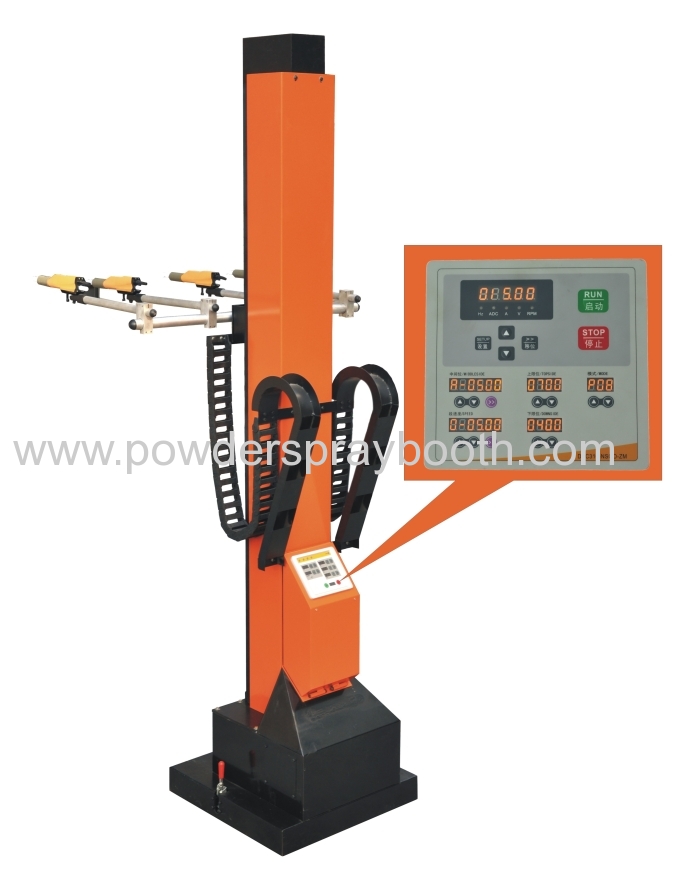

Gun Movers

Automatic Reciprocator (reciprocating machine) (Work with Electrostatic Powder Coating Gun) With several electrostatic powder coating gun on the reciprocator Japan Mitsubishi Transducer & PLC controlled

Four automatic spray gun rods(qty of the rods can be ordered)

The COLO-5000-800D Control system with the 800D automatic powder spray guns especially designed to meet the requirements of serial production in powder coating, where reliability in automated operation, easy to handle operation and security are the most projecting advantages for the user.

The type and the number of installed control units could make as your requirements.

Powder sieving machine

The system is able to continuously sent the powder being dropped during the process of spraying to the upper part of the butterfly powder screen and then the selected powder is sent to the centralized powder supply barrel which is in charge of continuously supplying powder to automatic guns or manual guns

The spray booth is manufacture according to your requirements.

All powder coating booths are formed on CNC equipment

Not to be used for wet painting

If you are an expanding manufacturer or new business,we can provide the necessary assistance in planning your process.