automatic Mono cyclone spray booth

| Trade Term: | EXW |

|---|---|

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 8 sets/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | COLO-S-C232 |

|---|---|

| Means of Transport: | Ocean |

| Categories: | Powder coating spray Booth |

| Brand: | COLO |

| Model: | COLO-S-C232 |

| powder recovery system: | mono cyclone |

| Demension of spray booth: | 2m*3m*2m |

| color: | grey |

| material: | steel coated |

| filter qty: | 9pcs |

| Voltage: | 380V 3phases |

| Frequency: | 50/60HZ |

| Production Capacity: | 8 sets/month |

| Packing: | wooden box |

| Delivery Date: | 25 days after payment |

Product Description

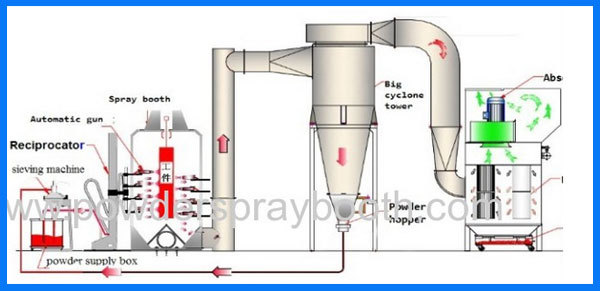

Drawing for Mono-cyclone and after filters recovery system powder spray booth

| Booth Type | Mono cyclone |

| Operator dimensions | 3000width x 2000 height x 1500 depth (1PC) |

| Overall dimensions | 3200width x 2200 height x 2000 depth |

| Weight | 1000kg |

| Power supply | Electric |

| Nominal power | 7.5kW |

| Voltage | 380V |

| Frequency | 50-60Hz |

| Filters | Polyester |

| Filters count | 9 |

| Filters hang type | easy for change |

| Filter cleaning system | Pneumatic |

| Warranty | 12 months |

Mono cyclone spray booth in the powder coating line

The working principle is based on centrifugal effect.

Extruded air and is forced spirally downwards by centrifugal force, sieved and brought back to the powder

hopper by a powder pump.

Alternative cyclone spray booth

The COLO Mono-cyclone has a specially constructed shape. It is conical from top to bottom. The

entry and the top part of the cyclone have been designed so as avoid the necessity to clean, even with

extreme colour changes. Additionally, the cyclone achieves a very high degree of effectiveness due to

the unconventional shape. On the bottom part of the cyclone, a pneumatic powder recovery system is

attached. The stand-alone system consists of a sieving device, peristaltic conveyor unit with control

and cleaning unit. The recovered powder is brought back to the powder centre by the peristaltic conveyor.

How to choose Different Models:

Depending upon size of the article, coating requirements, material handling requirements we have

designed some standard models. As a special requirement different customized models are also

developed.

Velocity of booth should be:

Appropriate enough so that maximum powder should be attracted on the article. | |

If suction velocity is more, more amount of powder will be sucked towards cyclone & less on article. | |

If suction velocity is less, then powder will come out from cutout & surroundings will be polluted. |

Spray booth Selection Criteria:

Easiness in colour change , No. of colour change ,Frequency of colour change. | |

Selection of Booth design. | |

Size of Article ,Weight of Article. | |

Selection & type of Track / Trolleys from 1 side or 2 sides. | |

System of track / trolleys. | |

Any other type of material handling. |