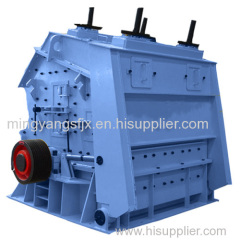

Product description:

Impact crusher is used in crushing all kinds of materials whose fineness is below 500mm,and the pressure resistance around 360mpa. It has the features of big crushing rate, efficient crushing, easy maintenance and cubic shape with final product. It is an ideal mining equipment for high road and water conservancy. With perfect features and good performance, impact crusher is widely used in high road construction, water conservancy and construction process of gravel and so on. It has a better ability in granite,limestone and cobble,etc.

Features:

1.It is used for crushing line of medium and fine material.

2. Big crushing ratio, it can simplify clinker primary & secondary crushing and limestones secondary& tertiary crushing into primary crushing, and reduce the power consumption by 30% with the same capacity.

3. The back cover in the top of the machine can be opened by hand. It is more convenient and quick to replace the parts. The newly high quality vanadium molybdenum multi-element alloy hammerhead can be turned around; the average life can be extended to 3-4 times.

4. Wearing parts are made of newly high quality multi-element and high wear resistance alloy materials, which can guarantee the wear resistance and impact resistance of the hammerhead and the liner.

Working principle:

When impact crusher works, the motor drives the rotor rotate with high speed, on the rotor where installed the hammers with high-tech raw material. When the crushed materials get into the impact crusher inner space where the hammers effect, under the impact function of the hammer at a high speed, the materials are thrown to the impact device above the rotor continuously. And then the materials are rebounded from the impact liner to the area where the hammers effects for being re-crushed. The materials from large to small all to be crushed at the impact crusher chamber repeatedly. The process won't stop till the materials in the impact crusher are crushed to the required size and then discharged from outlet.