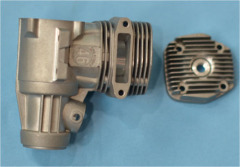

Aluminum Die Casting Part

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 100 |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Injection Mold, Casting Mould, Platic Tooling |

Product Detail

| Model No.: | XMTDC5 |

|---|---|

| Means of Transport: | Ocean |

| Product: | Household Appliance |

| Product Material: | Plastic |

| Shaping Mode: | Die Casting |

| Brand Name: | XMT |

| lkm mould base: | Die casting mould |

| Production Capacity: | 100 |

| Packing: | bulk pack |

| Delivery Date: | around 30 days |

Product Description

Aluminum Die Cast mould making and tooling

DieCasting mould making is more or less the same as injection mould. All the difference is the surfce handling which would require high quality polishing before plating the surface. This is well popular for the home appliant such as hand-washer, outdoor lamp covers. The quality looks and feels much better than plastic.

What we can do:

Our main business is Mould making, but we have couples of injection machine for mould testing. So we can also carry out plastic tooling. We have strong team to offer OEM and ODM service.We can make efficiently in accordance with your CAD OR 3D drawings, or rough sketches with your detailed specification and requirements.

How to make an inquiry:

Certain things need to be done prior to turning to us.

1) Have prototype(s) : this is the easiest way for project proceeding. All

you have to do is try to send the prototype(s)s for us to follow up and tell me if there is anything that you want to change.

2) Have CAD or 3D drawings with the exact specifications of everything: This would make us much easier. But due to different designer's different habits, we normally would need to take time to follow up their design and in accordance with our former experiences, sometimes, this would take more time than re-design it if the designer you turned to is not professional enough.

3) Have a rough sketches but with detailed specifications and angels: This would be the most difficult way for project proceeding. And normally, we would need lots of email or phone conversations to make sure every details before starting the design work.

4) Let me know the usage as detailed as possible: This sometimes is ignored due to some commercial secrets while it is very important. We have confronted lots of projects with this problem. Because for plastic part itself, it is very hard sometimes to adjust the usage, so sometimes we would put the injection pins on the surface, thus would take time and cost to revise it. Actually, if required, we can sign a "non-disclosure agreement" before project launching to avoid this problem.

Kind Note:

Most importantly you need to know, you have a "winner of a product" otherwise you are waisting your money. The bottom line is a "fancy prototype" with no commercial future is worthless compared to a "cocktail napkin drawing" with a great concept that can translate into a true commercial and profitable reality. So you have to due your "due diligence" FIRST.