shirt box waiting machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30sets/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Wenzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Gluing Machine, Folding Machine, Shoe Box Machine |

Product Detail

| Model No.: | LM-350-HCX |

|---|---|

| Means of Transport: | Ocean |

| Processing: | Packaging Line |

| Automatic Grade: | Automatic |

| Type: | Special |

| Usage: | Inner |

| Packaging: | Others |

| Brand Name: | LAOMO |

| Min /Max cardboard size of A: | 220/650mm |

| Min /Max cardboard size of B: | 350/700mm |

| Min /Max carton size of W: | 120/300mm |

| Min /Max carton size of L: | 200/350mm |

| Min /Max carton size of H: | 30/150mm |

| Heater power: | 5.5kw |

| Motor power: | 4.6kw |

| Working speed: | 46pcs/min |

| Dimension: | 4600*3000*240mm |

| Weight: | 2500kg |

| Production Capacity: | 30sets/month |

| Packing: | wooden case |

| Delivery Date: | 35days |

Product Description

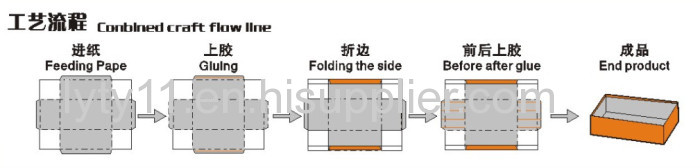

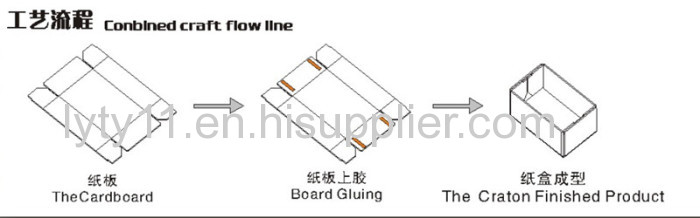

Full autoamtic cover box-pasting machine is a new auto equipment.The machine employs PLC,touch screen man-machine interface,photoelectric track system,servo control system and auto coating system.It can automatically convey,coat,fold,form and organize boxes,It can improve the production capacity by ten times,compared with the hand one .It is a good equipment for box manufacturers.

It can automatically suck and draw and wind paper from the bottom.it can precisely stably convey paper.

To fix,fold and coat with a fibre optical and reduce the error of coating.

The servo pushes the paperboard to and fro to coat which can reduce the error that the photoelecric shines the paperboard .thus it can accurately coat the paperboard.

The to and fro coaters employs dual gun splayed coaters. As a result,the paper box can be stuck flatly and firmly

The former employs a frequency linkage speed adjuster.Each unit is assembled with a safety protection system which can save the time to adjust

The former employs full sealed construction.each unit is assembled with a safety protection system,which makes it safer in operation.

PLC touch screen man machine interdace,photoelectric track system,servo control system are emplyed which can automatically form the paper boxes in one lot in the course of production

It has an automatic trouble diagnostic tester.It can shoot the trouble as long as they appear

Technical Variables:

Min/Max cardboard size of A: 220/650mm

Min/Max cardboard size of B: 350/700mm

Min/Max carton size of W: 120/300mm

Min/Max carton size of L: 200/350mm

Min/Max carton size of H: 30/150mm

Heater power: 5.5kw

Motor

power: 4.6kw

Working speed: 46pcs/min

Dimension (L*W*H): 4600*3000*2400mm

Weight: 2500kg

Feature:

1. Competitive

price.

2. Convenient opration.

3. High quality.

4. Stable

performance.

5. Rational construction.

6. Low power consumption.

7.

High efficiency.

8. Easy to maintain.

Why

US?

The Service We

Provide - We Take Care of Your Order

The Quality We Provide - Outstanding

Quality Assurance

Latest Technology.(International latest

technology, With the idea of " Cooperation, the Source Power of Development" ,

TONGYONG builds a creative team consisting of professors of engineering and all

kinds of technicists, and establishes the technology R&D center and 3D

simulation design system. Combining with experts at home and abroad and research

institutions, TONGYONG keeps on technology upgrading and rebuilding, following

the global trend of the post-press equipment and maintaining the dynamic

development and update. Moreover, to meet the latest demands from different

customers, TONGYONG develops various new products

annually.)

Standardization Production. (6S management, TONGYONG is

whole-hearted on each production process from raw materials, semi-finished

products assembling and finished products debugging to products packaging and

delivery. The disqualified products are timely handled with the properly

increased QC personnel to furthest ensure the 100% quality of TONGYONG

products.)

High-end Electric Appliance.(TONGYONG machine equips imported

components of famous brand. Such as Japan Omron PLC, Japan SMC Pneumatic

Components, France Schneider Electrical Components, Japan Yaskawa Servo Motor,

Italy GMG Motor, Germany P+F ultrasonic checker, America LEUZE Sensor etc. First

class quality, European UL and CE Standard.)

First-class

Performance.(Power save; larger size, faster speed, and higher

precision)

Distinctive Customer Service.(Every parts is marked with

serial number which makes the replacement and maintenance easy and

convenience)

If you have any question , please feel free to contact us!