Combined Bearing adjustable from outside for steel sections

| Min. Order: | 500 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 50,000 PER MONTH |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

Product Detail

| Model No.: | KRES.062 |

|---|---|

| Means of Transport: | Ocean, Air |

| Material of Outer Rings: | Steel UNI 16CrNi4 casehardened and tempered Final surface hardness 62+/-2Hrc |

| Material of Inner Rings: | Steel UNI 100Cr6 hardened and tempered Final surface hardness 62+/-2 Hrc |

| Material of Rolling Elements: | Steel UNI 100Cr6 hardened and tempered Final hardness 62+/-2 Hrc |

| Material of Eccentric Stud: | Steel UNI 16CrNi4 casehardened and tempered. Final surface hardness 62+/-2 HRc |

| Material of Main Stud: | Fe52C annealed to be easily welded |

| OD: | 62 mm |

| ID: | 30 mm |

| Production Capacity: | 50,000 PER MONTH |

| Packing: | WHITE BOX OR COLOR BOX PACKING |

| Delivery Date: | 35-40 DAYS |

Product Description

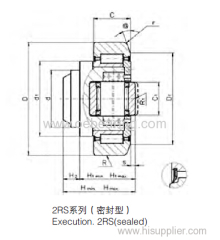

Technical Sheet

| JDA-bearing | Dimensions | Load ratings | Speed | Mass | ||||||||||||||||||

| 2RS | d | D | C | Hmin | Hmax | H1min | H1max | H2 | D1 | C1 | d1 | S | @ | r | R | R1 | C | CO | CA | COA | Grease | Kg |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Degree | mm | mm | mm | CN | CN | CN | CN | rev./min. | ||

| KRES.062 | 30 | 62 | 20 | 37.5 | 39 | 30.5 | 32 | 7 | 50 | 20 | 42 | 2 | 20º | 3 | 500 | 500 | 31 | 35.5 | 11 | 11.5 | 900 | 0.52 |

| KRES.070 | 35 | 70.1 | 23 | 44 | 45.5 | 36 | 37.5 | 8 | 57 | 22 | 48 | 2 | 20º | 3 | 500 | 500 | 45.5 | 51 | 14 | 13 | 900 | 0.78 |

| KRES.078 | 40 | 77.7 | 23 | 48 | 50 | 36.5 | 38.5 | 11.5 | 61 | 24 | 54 | 2.5 | 20º | 3 | 700 | 700 | 48 | 56.8 | 18 | 18 | 800 | 1.02 |

| KRES.089 | 45 | 88.9 | 30 | 57 | 59 | 44 | 46 | 13 | 68 | 26 | 59 | 3 | 20º | 4 | 700 | 700 | 68 | 72 | 23 | 23 | 700 | 1.61 |

| KRES.101 | 50 | 101.9 | 28 | 46 | 48.5 | 33 | 35.5 | 13 | 77 | 26 | 67 | 2.5 | 20º | 4 | 850 | 700 | 73 | 82 | 23 | 23 | 700 | 1.75 |

| KRES.108 | 60 | 107.7 | 31 | 69 | 71.5 | 55 | 57.5 | 14 | 82 | 34 | 71 | 3.5 | 20º | 4 | 1000 | 700 | 81 | 95 | 31 | 36 | 650 | 2.69 |

| KRES.123 | 60 | 123 | 37 | 72.3 | 75.3 | 56 | 59 | 16.3 | 92 | 40 | 80 | 4.5 | 20º | 4 | 1000 | 700 | 110 | 132 | 43 | 50 | 500 | 3.88 |

| KRES.149 | 55 | 149 | 43 | 78.5 | 81.5 | 58.5 | 61.5 | 20 | 116 | 50 | 103 | 4.5 | 15º | 4 | 1000 | 700 | 151 | 192 | 68 | 71 | 400 | 6.65 |

Dimensional Tolerances, clearances, load factors

| Tolerances | According to DIN 620 | |||||||

| Tolerance class | P"0" | |||||||

| Radial Clearance | According to DIN 620 | |||||||

| Load Rating | According to ISO 76 and ISO 281 | |||||||

Application

The combined bearings which are "adjustable from outside" have been designed to make the recovery of the lateral clearances in handling systems easier. The method to adjust them is of easy execution and will keep the performances of the bearing intact.

Recommended method of adjustment:

Turn the grub screws out with a hexagonal wrench.

Turn the TSEI screws with a hexagonal wrench.

Turn the adjustalbe pin using the holes, which are at the side of the axial part, with the help of a driver. This operation permits to have the requested adjustment.

Having checked the new adjustment, close without tightening the TSEI screws.

Turn the grub screws in. The exact position of the eccentric pin will be thus defined.

Tighten the TSEI screws strictly. The bearing is in standard position.