Ball Mill Spare Parts

| Min. Order: | 1 Metric Ton |

|---|---|

| Trade Term: | EXW |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 1000 Ton/Tons per Month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean, Air |

|---|---|

| Brand Name: | ys |

| name: | Ball Mill Spare Parts,Ball Mill Spares, Ball Mill Parts |

| certification: | .CE, ISO9001 and TUV |

| color: | any color is ok |

| Production Capacity: | 1000 Ton/Tons per Month |

| Packing: | Export standard |

| Delivery Date: | 25-30 workingdays after receiving deposit |

Product Description

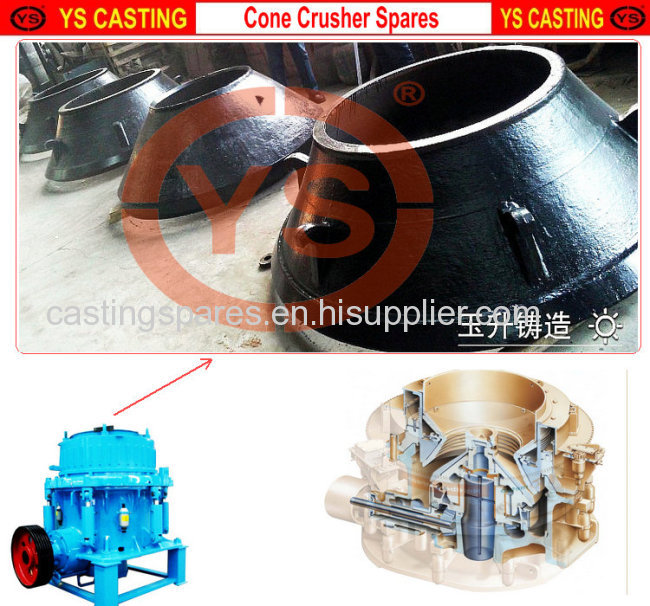

Introduction of Ball Mill Spare Parts

Yusheng's Ball Mill Spare Parts is designed together with the machine to ensure the best possible crushing performance. Absolutely correct dimensions and solid casting quality protect your crusher from overload danger.

Generally we use all steel bar, we also package according to our client's requirement.

Generally we use all steel bar, we also package according to our client's requirement.

Yusheng process wear resistant mining machine spares such as jaw

plate, wear hammer and cone concave in a variety of methods to meet

customer specifications in order to satisfy a diverse range of

applications.

1.How is the material of your product?

Material | C | Mn | Cr | Si | Mo | Ni | Cu |

Mn13Cr2 | 1.0~1.4 | 12~15 | 1.7~2.2 | 0.3~1.0 | |||

Mn18Cr2 | 1.0~1.4 | 17~19 | 1.8~2.2 | 0.3~1.0 | |||

Cr12 | 2.0~3.3 | ≤2.0 | 11~14 | ≤1.2 | ≤3.0 | ≤2.5 | ≤1.2 |

Cr15 | 2.0~3.3 | ≤2.0 | 11~14 | ≤1.2 | ≤3.0 | ≤2.5 | ≤1.2 |

Cr20 | 2.0~3.3 | ≤2.0 | 14~18 | ≤1.2 | ≤3.0 | ≤2.5 | ≤1.2 |

Cr26 | 2.0~3.3 | ≤2.0 | 23~30 | ≤1.2 | ≤3.0 | ≤2.5 | ≤2.0 |

2.How could I prepare to send inquiry to you?

Please kindly send us message or email online regarding your desired spare parts info and drawing or images.

3.How is your packing of products?

Generally we use all steel bar, we also package according to our client's rerquirement.

4.How long could you manufacture and deliver your products?

We manufacture the wear-resistant spares between 25 and 45 days, delivery is within 5 workdays after our manufacturing and QC.