Fully automatic eletromagnetic dried-powder iron-remover machine magnetic separator price magnetic separator with ISO

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 10-20t/h |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Stone Crusher, Ball Mill, Magnetic Separator |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Application: | Ore |

| Type: | Separator |

| Brand Name: | Zhongke |

| Product name: | Fully automatic eletromagnetic dried-powder iron-remover machine magnetic separator price,magnetic separator with ISO |

| Dia of shell: | 1200mm |

| Length of shell: | 2400mm |

| Rotary speed of cylinder: | <18rpm |

| Feeding size: | 3-0mm |

| Capacity: | 85-180t/h |

| Power: | 5.5T |

| Condition: | New |

| Brand name: | Kuangyan |

| Voltage: | 380/220v |

| Production Capacity: | 10-20t/h |

| Packing: | international standard export packing |

| Delivery Date: | 20 days after receive deposite payment |

Product Description

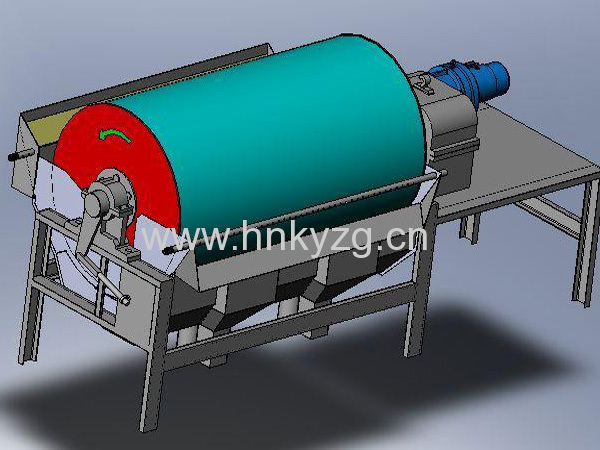

Introuduce of magnetic separator.

Suspension overbandmagnetic separator sometimes also called overbelt separators consist essentially of a magnet (electro or permanent type) around which a belt called iron discharging belt. The machines featured by a permanent magnet are called model RCY, by an electromagnet model RCD.

Suspension overband magnetic separator usually suspend on the onveyor or over the head pulley.

Suspension overband magnetic separator is widely used together with various kinds of belt conveyors for auto iron removal from non-magnetic materials in continuous duty occasions with plenty of iron.

Suspension overband magnetic separator can protect downstream important and in most cases very expensive equipments from being potentially damaged by tramp metal.

Wet magnetic separator

This series of products is used in wet magnetic separation of materials with granularity below 3mm like magnetite, pyrrhotine, bake ore and washingtonite.. They remove contaminants from the product stream, increasing product purity and plant productivity. In the applications where the product purity is most essential the wet drum separators can use powerful rare earth magnets which can remove very fine and weak contaminants even from dense materials.

Magnetic Separator is a device which is designed to assist with the purification and separation of process streams. The heart of each separator is magnetic system, which adopts high quality ferrite materials and rare earth magnets, the average magnetic induction intensity on the shell surface is 100~600mT. This product has the advantages of simple structure, big processing capacity, convenient operation and easy maintenance.

Application

Magnetic separator is suitable for the wet magnetic separation of the materials whose granularity is below 3mm such as magnetite, pyrrhotite, calcined ore, ilmenite etc, and can also be used for iron removal work from coal, non-metal ore and construction materials.

The wet type permanent-magnetic cylindrical separator is a common magnetic separator that can be widely used in iron ore separation. It is suitable for separating strong magnetic minerals. In recent years, it's also used as concentrating equipment for replacing the magnetic dewatering tank before filtration.

Main technical parameters

Model | Dia.of shell(mm) | Length of shell(mm) | Rotary speed of cylinder(r/min) | Feeding size(mm) | Capacity(t/h) | Power(kw) |

CTB6012 | 600 | 1200 | <35 | 2-0 | 10-20 | 1.5 |

CTB6018 | 600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

CTB7518 | 750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

CTB9018 | 900 | 1800 | <35 | 3-0 | 40-60 | 3 |

CTB9021 | 900 | 2100 | <35 | 3-0 | 45-60 | 3 |

CTB9024 | 900 | 2400 | <28 | 3-0 | 45-70 | 4 |

CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

CTB1021 | 1050 | 2100 | <20 | 3-0 | 50-100 | 5.5 |

CTB1024 | 1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

CTB1218 | 1200 | 1800 | <18 | 3-0 | 80-140 | 5.5 |

CTB1224 | 1200 | 2400 | <18 | 3-0 | 85-180 | 7.5 |

CTB1230 | 1200 | 3000 | <18 | 3-0 | 100-180 | 7.5 |

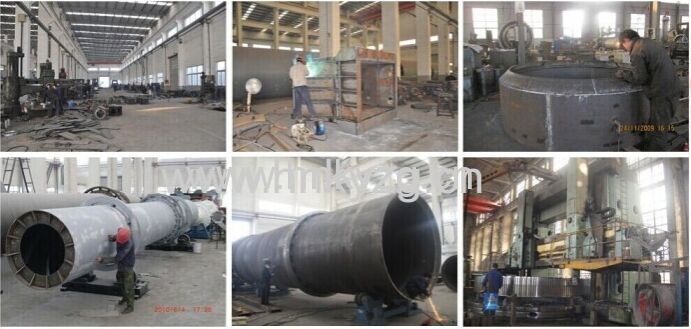

Company profile

Henan Kuangyan Industrial Heavy Mahinery Co., Ltd. is specialized in heavy equipment like various crushers, magnetic separators, mining machines, bricks and blocks machines, cement production line, AAC block line, etc., which is located in the middle of China. Our competitive price, high quality products and excellent after-sales service had gain us good reputation in this field.

Crushing equipment: jaw crusher, impact crusher,cone crusher, hammer crusher, sand making machine, vibrating feeder,vibrating screen;

Mine-dressing equipment: ball mill, spiral chute, classifier, flotation machine, magnetic separator;

Building material equipment: rotary dryer, rotary kiln, autoclave aerated concrete equipment (AAC plant)

Production line: sand production line, stone production line, active lime production line, cement production line, AAC block plant

Our company is headquartered in Zhengzhou Country's High-tech Industrial Development Zone, which consists of three branches, a research and development department. Since the establishment of the company, always adopt advanced modern management system, and focused on innovation, has brought together a number of scientific and technological elite, the company employees is more than 500people now, with 20 senior engineers, and more than 100 midding technicians. The company has long-term cooperation with domestic scientific research units, has introduced advanced technology, technics and testing system at home and abroad.

Our service:

1. Pre-sales services:

1) Select proper equipment model;

2) Design and manufacture products according to clients' special requirement;

3) Arrange for visiting our factory, assist them to handle relative procedure, such as visa.

2. Services during the sale:

1) Make sure goods prepared within delivery time;

2) Pre-check and accept products ahead of delivery;

3) Prepare documents required to help customer pass customs clearance;

4) Help clients to make Project evaluation and feasibility analysis and draft solving plans.

3. After-sales services:

1) Assist clients to prepare for the first construction scheme;

2) Install, debug and examine the equipment;

3) Train technical personnel the first-line operators;

4) Provide technical exchanging;

5) Offer spare parts at a best price for long term.

Note: Responsible for handling other required matters conforming the state regulations