customized high performance automatic iron filter magnetic seperator for powder

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 10-20t/h |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Stone Crusher, Ball Mill, Magnetic Separator |

Product Detail

| Model No.: | CTB6018 |

|---|---|

| Means of Transport: | Ocean |

| Application: | Ore |

| Type: | Separator |

| Brand Name: | Zhongke |

| Product name: | customized high performance automatic iron filter magnetic seperator for powder |

| Dia of shell: | 600mm |

| Length of shell: | 1800mm |

| Rotary speed of cylinder: | <35rpm |

| Feeding size: | 2-0mm |

| Capacity: | 15-30t/h |

| Power: | 2.2T |

| Condition: | New |

| Brand name: | Kuangyan |

| Voltage: | 380/220v |

| Production Capacity: | 10-20t/h |

| Packing: | international standard export packing |

| Delivery Date: | 20 days after receive deposite payment |

Product Description

Mining Machine Magnetic Seperator

1.The wet type permanentmagnetic cylindrical separator is a common magnetic separator that can

be widely used in iron ore separation. It is suitable for separating strong magnetic minerals.

2. The magnetic system of magnetic separator is a compound of fine ferrite material and rare earth

magnets and the average magnetic induction intensity of the surface of the cylinder is 100~600mT.

Magnetic separator is one of aircraft which is the most widely used and high versatility in industries.

Application Mining Machine Magnetic Seperator

1.Magnetic separator is suitable for the wet magnetic separation of the materials whose granularity is

below 3mm such as magnetite, pyrrhotite, calcined ore and ilmenite and can also be used for

removing iron from the materials such as coal, nonmetal ore and building material.

2.Magnetic separator can be divided into three types according to trough's different structure. They

are downstream type, semi-reflux type and reflux-type.

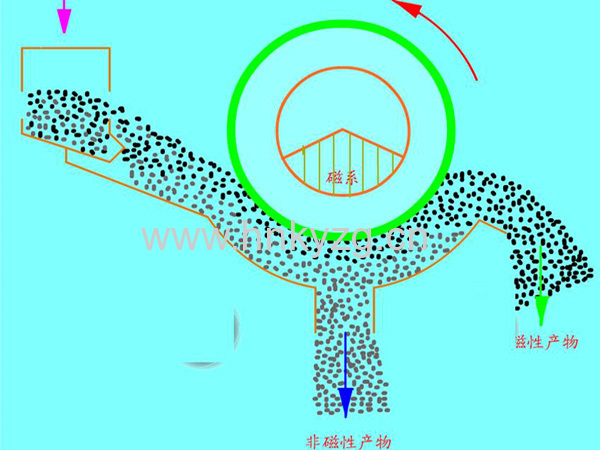

Working priciple Mining Machine Magnetic Seperator

The wet type permanentmagnetic cylindrical separator is mainly composed of cylinder, magnetic

system, trough and transmission part.After the ore slurry running into the trough through ore box and

effected by the feeding ore water pipe, the ore particles can enter into the ore feeding area in trough.

The magnetic ore particles can form 'magnet group' or 'magnet chain' by magnetic field's affect. All

the 'magnet group' or 'magnet chain' moves to magnetic poles because of magnetic force in the ore

slurry and then they can be attached to the cylinder. Since the polarity of magnetic poles are arrayed alternately and fixed tightly when working, when 'magnet group' or 'magnet chain' turning with the

cylinder, the non magnetic materials, such as matrix which are mixed with 'magnet group' or 'magnet chain' will drop down during the rolling process. Eventually, the 'magnet group' or 'magnet chain'

attached to the cylinder surface are fine ore. When the fine ore turn to the weakest place of magnetic system in the cylinder, it will be pushed to the fine ore trough by the water coming from unloadore pipe. Non magnetic or weak magnetic ore are left in the ore slurry and then discharged out of the trough,

these ore are the gangue. Some magnetic ore can be recycled by putting the gangue in magnetic

separator again and then the recycle rate can be increased much. The fine ore can pass through the magnetic separator again and the matrix which mixing with the fine ore can be wiped out to upgrade

the purity of fine ore.

Features and advantages Mining Machine Magnetic Seperator

1)The separator can be made of rollshaped whose magnetic strength can also be improved to

8000mT, which has been the highest magnetic field strength all over the world.

2) It has short magnetic circuit, little magnetic flux leakage, high magnetic intensity, low energy

consumption, fine beneficiating results.

Main technical parameters

Model | Dia.of shell(mm) | Length of shell(mm) | Rotary speed of cylinder(r/min) | Feeding size(mm) | Capacity(t/h) | Power(kw) |

CTB6012 | 600 | 1200 | <35 | 2-0 | 10-20 | 1.5 |

CTB6018 | 600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

CTB7518 | 750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

CTB9018 | 900 | 1800 | <35 | 3-0 | 40-60 | 3 |

CTB9021 | 900 | 2100 | <35 | 3-0 | 45-60 | 3 |

CTB9024 | 900 | 2400 | <28 | 3-0 | 45-70 | 4 |

CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

CTB1021 | 1050 | 2100 | <20 | 3-0 | 50-100 | 5.5 |

CTB1024 | 1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

CTB1218 | 1200 | 1800 | <18 | 3-0 | 80-140 | 5.5 |

CTB1224 | 1200 | 2400 | <18 | 3-0 | 85-180 | 7.5 |

CTB1230 | 1200 | 3000 | <18 | 3-0 | 100-180 | 7.5 |

Company profile

Henan Kuangyan Industrial Heavy Mahinery Co., Ltd. is specialized in heavy equipment like various crushers, magnetic separators, mining machines, bricks and blocks machines, cement production line, AAC block line, etc., which is located in the middle of China. Our competitive price, high quality products and excellent after-sales service had gain us good reputation in this field.

Crushing equipment: jaw crusher, impact crusher,cone crusher, hammer crusher, sand making machine, vibrating feeder,vibrating screen;

Mine-dressing equipment: ball mill, spiral chute, classifier, flotation machine, magnetic separator;

Building material equipment: rotary dryer, rotary kiln, autoclave aerated concrete equipment (AAC plant)

Production line: sand production line, stone production line, active lime production line, cement production line, AAC block plant

Our company is headquartered in Zhengzhou Country's High-tech Industrial Development Zone, which consists of three branches, a research and development department. Since the establishment of the company, always adopt advanced modern management system, and focused on innovation, has brought together a number of scientific and technological elite, the company employees is more than 500people now, with 20 senior engineers, and more than 100 midding technicians. The company has long-term cooperation with domestic scientific research units, has introduced advanced technology, technics and testing system at home and abroad.

Our service:

1. Pre-sales services:

1) Select proper equipment model;

2) Design and manufacture products according to clients' special requirement;

3) Arrange for visiting our factory, assist them to handle relative procedure, such as visa.

2. Services during the sale:

1) Make sure goods prepared within delivery time;

2) Pre-check and accept products ahead of delivery;

3) Prepare documents required to help customer pass customs clearance;

4) Help clients to make Project evaluation and feasibility analysis and draft solving plans.

3. After-sales services:

1) Assist clients to prepare for the first construction scheme;

2) Install, debug and examine the equipment;

3) Train technical personnel the first-line operators;

4) Provide technical exchanging;

5) Offer spare parts at a best price for long term.

Note: Responsible for handling other required matters conforming the state regulations