Ball mill is suitable for mineral processing, cement, lime, crushing, etc

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 30 sets/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Stone Crusher, Ball Mill, Magnetic Separator |

Product Detail

| Model No.: | MB2736 |

|---|---|

| Means of Transport: | Ocean |

| Application: | Ore |

| Type: | Mill |

| Brand Name: | Kuangyan |

| Cylinder(D*L): | 2700*3600 |

| Balls Weight: | 42t |

| Rotary speed: | 17.5rpm |

| Discharging size: | 5-0.8mm |

| Capacity: | 150-45t/h |

| Motor power: | 355kw |

| Weight: | 82t |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| Certification: | CE,CQC,ISO |

| Payment Terms: | 30% T/T, 70% before shipment |

| Production Capacity: | 30 sets/month |

| Packing: | standard export package, nude pack, container, spare parts in wooden case |

| Delivery Date: | within 30-45 days upon the receipt of deposit |

Product Description

Feature of Ball mill

1.This type of ball mill is a kind of traditional ball mill,with sliding bearings(Babbit metal bearing bushing seat)

2.Simple structure, and split installation.

3.It is easy to lift it while installing and maintaining.

4.Its feeders are classified into two types:combined feeder and cylinder feeder.

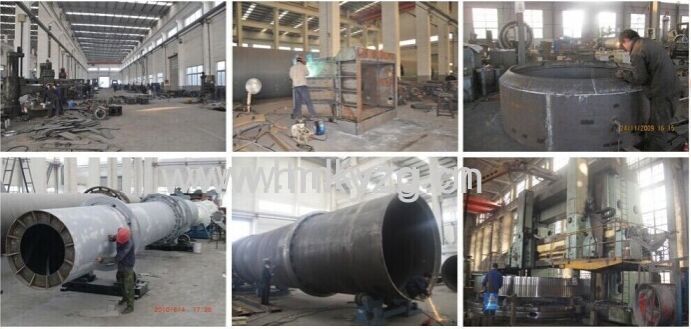

To make sure ball grinding mill to work stablely and finish production tast, We frist make sure our manufacture tool and strict inspection daily work.

ball mill Introduction

The ball mill is widely used to grind various ores and other materials in mining, building materials, chemical industries, etc. The ball mill can be divided into dry type and wet type according to the milling method; grid type and overflow type or center-discharge and side-discharge type according to the ways of discharge; bearing-mill and bearing pad millaccording to the different methods of supporting; rim drive and center drive according to the different ways of transmission. Large mill 3 meters above is especially configured with jack-up devices for easy maintenance; the dynamical pressure bearing and the static pressure bearing can operate stably. Slow rotation is convenient for overhaul and start; the oil sprayer lubrication device can make big and small gears reliable. The main motor of large mill is high pressure asynchronous motor or synchronous motor, which should be notified in the orders.

Working Principle:

The ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft evenly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height to impact and grind the materials. The grinded materials are discharged through the discharging board thus the grinding process is finished.

Application of ball mill:

Ball mill is the key equipment for grinding after the crush process, and it is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics.

It also can be used for the dry and wet grinding for all kinds of ores and other grind-able materials.

Main technical prameters

Model | Cylinder size (D×L) (mm) | Effective volume (m³) | Balls weight(t) | Rotating speed(r/min) | Power(kw) | Discharge size(mm) | Capacity(t/h) | Weight(t) |

MB0918 | 900×1800 | 0.85 | 2.3 | 38 | 22 | 2.5-0.2 | 6-1.6 | 6.2 |

MB0924 | 900×2400 | 1.15 | 3.1 | 38 | 30 | 2.5-0.2 | 10-2.9 | 6.6 |

MB1224 | 1200×2400 | 2.2 | 6.5 | 32 | 55 | 2.5-0.2 | 13-5 | 13.5 |

MB1530 | 1500×3000 | 5.0 | 8 | 27 | 75 | 2.5-0.2 | 12-5.5 | 16.7 |

MB1830 | 1800×3000 | 6.5 | 17 | 22.8 | 132 | 2.5-0.2 | 20-9.5 | 29.8 |

MB2122 | 2100×2200 | 6.7 | 18 | 20.9 | 160 | 2.5-0.2 | 27-12 | 42.5 |

MB2130 | 2100×3000 | 9.2 | 25 | 20.9 | 160 | 2.5-0.2 | 30-13 | 43.9 |

MBZ2136 | 2100×3600 | 11.0 | 28 | 20.9 | 200 | 2.5-0.2 | 35-14.8 | 49.4 |

MB2140 | 2100×3600 | 11.0 | 32.5 | 20.9 | 210 | 2.5-0.2 | 61.5-43 | 49.9 |

MB2145 | 2100×4000 | 12.2 | 31 | 20.9 | 220 | 2.5-0.2 | 38-17 | 50.3 |

MBZ2430 | 2100×4500 | 13.8 | 35 | 20.9 | 250 | 2.5-0.2 | 43-19 | 51.8 |

MB2430 | 2400×3000 | 12.2 | 31 | 19 | 250 | 2.5-0.2 | 47-22 | 56.0 |

MB2430 | 2400×3000 | 12.2 | 31 | 19 | 250 | 2.5-0.2 | 73-52 | 58.3 |

MB2436 | 2400×3600 | 14.6 | 37 | 19 | 280 | 2.5-0.2 | 55-26 | 61.0 |

MB2436 | 2400×3600 | 14.6 | 37 | 19 | 280 | 2.5-0.2 | 84-60 | 62.4 |

MB2730 | 2700×3000 | 15.3 | 35 | 17.5 | 315 | 5-0.8 | 125-37.5 | 75.6 |

MB2736 | 2700×3600 | 18.4 | 42 | 17.5 | 355 | 5-0.8 | 150-45 | 81.8 |

MB2740 | 2700×4000 | 20.5 | 47 | 17.5 | 400 | 5-0.8 | 165-50 | 84.3 |

MB3040 | 3000×4000 | 25.9 | 50 | 16.2 | 500 | 5-0.8 | 206-62 | 130 |

MB3245 | 3200×4500 | 33 | 56 | 15.5 | 630 | 5-0.8 | 228-70 | 138 |

MB3248 | 3200×4800 | 34 | 60 | 15.5 | 710 | 5-0.8 | 240-74 | 142 |

MB3645 | 3600×4500 | 40.8 | 78 | 14.5 | 800 | 5-0.8 | 270-83 | 168 |

MB3654 | 3600×5400 | 50 | 94 | 14.5 | 1000 | 5-0.8 | 340-103 | 192 |

Company profile

Henan Kuangyan Industrial Heavy Mahinery Co., Ltd. is specialized in heavy equipment like various crushers, magnetic separators, mining machines, bricks and blocks machines, cement production line, AAC block line, etc., which is located in the middle of China. Our competitive price, high quality products and excellent after-sales service had gain us good reputation in this field.

Crushing equipment: jaw crusher, impact crusher,cone crusher, hammer crusher, sand making machine, vibrating feeder,vibrating screen;

Mine-dressing equipment: ball mill, spiral chute, classifier, flotation machine, magnetic separator;

Building material equipment: rotary dryer, rotary kiln, autoclave aerated concrete equipment (AAC plant)

Production line: sand production line, stone production line, active lime production line, cement production line, AAC block plant

Our company is headquartered in Zhengzhou Country's High-tech Industrial Development Zone, which consists of three branches, a research and development department. Since the establishment of the company, always adopt advanced modern management system, and focused on innovation, has brought together a number of scientific and technological elite, the company employees is more than 500people now, with 20 senior engineers, and more than 100 midding technicians. The company has long-term cooperation with domestic scientific research units, has introduced advanced technology, technics and testing system at home and abroad.

Our service:

1. Pre-sales services:

1) Select proper equipment model;

2) Design and manufacture products according to clients' special requirement;

3) Arrange for visiting our factory, assist them to handle relative procedure, such as visa.

2. Services during the sale:

1) Make sure goods prepared within delivery time;

2) Pre-check and accept products ahead of delivery;

3) Prepare documents required to help customer pass customs clearance;

4) Help clients to make Project evaluation and feasibility analysis and draft solving plans.

3. After-sales services:

1) Assist clients to prepare for the first construction scheme;

2) Install, debug and examine the equipment;

3) Train technical personnel the first-line operators;

4) Provide technical exchanging;

5) Offer spare parts at a best price for long term.

Note: Responsible for handling other required matters conforming the state regulations