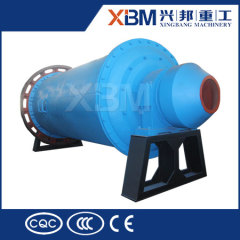

Powder ball mill machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 30 sets/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Stone Crusher, Ball Mill, Magnetic Separator |

Product Detail

| Model No.: | MB0924 |

|---|---|

| Means of Transport: | Ocean |

| Application: | Ore |

| Type: | Mill |

| Brand Name: | Kuangyan |

| Cylinder(D*L): | 900*2400 |

| Balls Weight: | 3.1t |

| Rotary speed: | 38rpm |

| Discharging size: | 2.5-0.2mm |

| Capacity: | 10-2.9t/h |

| Motor power: | 30kw |

| Weight: | 6.2t |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| Certification: | CE,CQC,ISO |

| Payment Terms: | 30% T/T, 70% before shipment |

| Production Capacity: | 30 sets/month |

| Packing: | standard export package, nude pack, container, spare parts in wooden case |

| Delivery Date: | within 30-45 days upon the receipt of deposit |

Product Description

Powder Mill Machine :

Superfine Powder Mill is a new product absorbed high tech abroad. Power (325- 3000mesh) is made by roller with stress milling materials90- 15mm) on millstone. The full contact among roller ,millstone ,materials and precision of grading system shows the high tech. Under the same conditions, the production capacity and fineness is three times and 500 mesh higher than that of Raymond and medium speed mill respectively, exceeding the fineness limit of wet stirred mill, which, has been the first choice of high tech, efficiency and energy- saving mill. This mill is ideally suitable for metallurgy, electricity, chemical,cement, refractory especially non-metallic minerals.

The integration of milling, power selecting and drying makes it more convenient.Compared with other mills, it possesses more advantages:high efficiency,energy saving, less consumption,optimum milling and drying performance,easy adjustment of fineness and replacement of quick wear part uniform particles, less noise and dust, simple flow and operation, small volume,better economic benefits,which, receives more and more attention and has been widely used for the milling of calcium carbonate, quartz, fluorite, calcite,stone, filaments, electrolytic manganese,silicon metal etc.

Technology innovation of SLVTM Superfine Powder Mill :when millstone and roller rotate driven by electric motor through speed reducer and belt respectively, hot air is sent into the mill and materials falling on the millstone move to the edge driven by centrifugal force and milled when going through the ring groove on millstone,with the effect of high speed airflow,qualified powder is sent into pollination device while large particles fall onto the millstone for a second time milling . Wet materials is dried by hot air .

Advantages of Powder Mill Machine :

(1). Low cost. Less energy consumption,high efficiency, 40 50% electricity is saved compared with ball mill and Raymond mill. The special material makes roller sleeve and lining board durable and low cost, also decreases the pollution of product. External circulation device can further reduces power consumption and improves product accuracy.

(2). Low construction cost.The integration of crushing,drying, milling, grading and conveying makes the area it covered decreases by 70% compared with ball mill.

(3). Easy operation. Equipped with automatic control and separation device between roll sleeve and lining board, it can be controlled remotely and no destructive vibration will happen.

(4). Easy maintenance. Roller sleeve and hard wearing inner wear can be changed just by overhauling the sliding frame of hydro-cylinder. Material of hard-wearing ring is 50SiMn.

(5). Less pollution, vibration and noise. Negative pressure operation and no dust overflow.

(6). High quality. It is easy to check and control chemical composition of product, high precision classifier it equipped can grade product of 325 mesh accurately, making final product with high quality.

Main technical parameters

Model | Cylinder size (D×L) (mm) | Effective volume (m³) | Balls weight(t) | Rotating speed(r/min) | Power(kw) | Discharge size(mm) | Capacity(t/h) | Weight(t) |

MB0918 | 900×1800 | 0.85 | 2.3 | 38 | 22 | 2.5-0.2 | 6-1.6 | 6.2 |

MB0924 | 900×2400 | 1.15 | 3.1 | 38 | 30 | 2.5-0.2 | 10-2.9 | 6.6 |

MB1224 | 1200×2400 | 2.2 | 6.5 | 32 | 55 | 2.5-0.2 | 13-5 | 13.5 |

MB1530 | 1500×3000 | 5.0 | 8 | 27 | 75 | 2.5-0.2 | 12-5.5 | 16.7 |

MB1830 | 1800×3000 | 6.5 | 17 | 22.8 | 132 | 2.5-0.2 | 20-9.5 | 29.8 |

MB2122 | 2100×2200 | 6.7 | 18 | 20.9 | 160 | 2.5-0.2 | 27-12 | 42.5 |

MB2130 | 2100×3000 | 9.2 | 25 | 20.9 | 160 | 2.5-0.2 | 30-13 | 43.9 |

MBZ2136 | 2100×3600 | 11.0 | 28 | 20.9 | 200 | 2.5-0.2 | 35-14.8 | 49.4 |

MB2140 | 2100×3600 | 11.0 | 32.5 | 20.9 | 210 | 2.5-0.2 | 61.5-43 | 49.9 |

MB2145 | 2100×4000 | 12.2 | 31 | 20.9 | 220 | 2.5-0.2 | 38-17 | 50.3 |

MBZ2430 | 2100×4500 | 13.8 | 35 | 20.9 | 250 | 2.5-0.2 | 43-19 | 51.8 |

MB2430 | 2400×3000 | 12.2 | 31 | 19 | 250 | 2.5-0.2 | 47-22 | 56.0 |

MB2430 | 2400×3000 | 12.2 | 31 | 19 | 250 | 2.5-0.2 | 73-52 | 58.3 |

MB2436 | 2400×3600 | 14.6 | 37 | 19 | 280 | 2.5-0.2 | 55-26 | 61.0 |

MB2436 | 2400×3600 | 14.6 | 37 | 19 | 280 | 2.5-0.2 | 84-60 | 62.4 |

MB2730 | 2700×3000 | 15.3 | 35 | 17.5 | 315 | 5-0.8 | 125-37.5 | 75.6 |

MB2736 | 2700×3600 | 18.4 | 42 | 17.5 | 355 | 5-0.8 | 150-45 | 81.8 |

MB2740 | 2700×4000 | 20.5 | 47 | 17.5 | 400 | 5-0.8 | 165-50 | 84.3 |

MB3040 | 3000×4000 | 25.9 | 50 | 16.2 | 500 | 5-0.8 | 206-62 | 130 |

MB3245 | 3200×4500 | 33 | 56 | 15.5 | 630 | 5-0.8 | 228-70 | 138 |

MB3248 | 3200×4800 | 34 | 60 | 15.5 | 710 | 5-0.8 | 240-74 | 142 |

MB3645 | 3600×4500 | 40.8 | 78 | 14.5 | 800 | 5-0.8 | 270-83 | 168 |

MB3654 | 3600×5400 | 50 | 94 | 14.5 | 1000 | 5-0.8 | 340-103 | 192 |

Company profile

Henan Kuangyan Industrial Heavy Mahinery Co., Ltd. is specialized in heavy equipment like various crushers, magnetic separators, mining machines, bricks and blocks machines, cement production line, AAC block line, etc., which is located in the middle of China. Our competitive price, high quality products and excellent after-sales service had gain us good reputation in this field.

Crushing equipment: jaw crusher, impact crusher,cone crusher, hammer crusher, sand making machine, vibrating feeder,vibrating screen;

Mine-dressing equipment: ball mill, spiral chute, classifier, flotation machine, magnetic separator;

Building material equipment: rotary dryer, rotary kiln, autoclave aerated concrete equipment (AAC plant)

Production line: sand production line, stone production line, active lime production line, cement production line, AAC block plant

Our company is headquartered in Zhengzhou Country's High-tech Industrial Development Zone, which consists of three branches, a research and development department. Since the establishment of the company, always adopt advanced modern management system, and focused on innovation, has brought together a number of scientific and technological elite, the company employees is more than 500people now, with 20 senior engineers, and more than 100 midding technicians. The company has long-term cooperation with domestic scientific research units, has introduced advanced technology, technics and testing system at home and abroad.

Our service:

1. Pre-sales services:

1) Select proper equipment model;

2) Design and manufacture products according to clients' special requirement;

3) Arrange for visiting our factory, assist them to handle relative procedure, such as visa.

2. Services during the sale:

1) Make sure goods prepared within delivery time;

2) Pre-check and accept products ahead of delivery;

3) Prepare documents required to help customer pass customs clearance;

4) Help clients to make Project evaluation and feasibility analysis and draft solving plans.

3. After-sales services:

1) Assist clients to prepare for the first construction scheme;

2) Install, debug and examine the equipment;

3) Train technical personnel the first-line operators;

4) Provide technical exchanging;

5) Offer spare parts at a best price for long term.

Note: Responsible for handling other required matters conforming the state regulations