Rotary kiln in rotary drying equipment

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | EXW |

| Payment Terms: | T/T |

| Supply Ability: | 25 sets per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Stone Crusher, Ball Mill, Magnetic Separator |

Product Detail

| Model No.: | YZ1225 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | Henan Kuangyan |

| product name: | Rotary kiln in rotary drying equipment |

| Barerl diameter: | 1200mm |

| Barrel length: | 25000mm |

| Slop: | 4 |

| Capacity: | 3t/h |

| Speed: | 0.53-5.25rpm |

| Motor power: | 22kw |

| Weight: | 34t |

| Condition: | New |

| Warranty: | 12 month |

| Production Capacity: | 25 sets per month |

| Packing: | international standard export packing machine |

| Delivery Date: | 25-30 days after receive deposite payment |

Product Description

Rotary kiln information

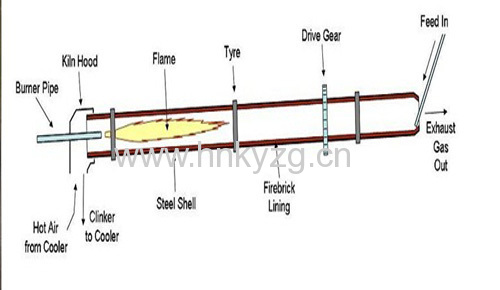

Rotary kiln is composed of cylinder, gears, support device, kiln liner and kiln tail sealing equipment, kiln head hood and combustion. Cylinder as heated pivoting part, made of high-quality carbon steel plate.

The rotary kiln refers to the rotation calcining kiln (known as rotary kiln), belonging to the building material equipment, which can be divided into cement kiln, metallurgy chemical kiln and lime kiln according to different materials. The Cement kiln is mainly used for calcining cement clinker, including dry and wet-producing cement kiln. The metallurgy chemical kiln is mainly used for lean iron ore magnetized roasting in steel plants of metallurgical industry; chromium and nickel iron ore oxidizing roasting; bauxite roasting in refractory plants and chamotte and aluminum hydroxide roasting in aluminium factory; chrome ore roasting in chemical plant. The lime kiln (i.e. active lime kiln) is used for roasting active lime and light burned dolomite for steel plants and ferroalloy works.

Rotary Kiln refers to rotating calcination kiln, belongs to construction material equipment. According to the different materials, the kiln can be divided into cement kiln, metallurgy chemical kiln and lime kiln. The cement kiln is mainly used for the calcinations of cement clinker, and it has two types of dry and wet methods. And the metallurgy chemical kiln is mainly applied in metallurgy industries, like, magnetizing roast of the poor iron ore in ironworks, oxidizing roast of the chromium and nickel ore, roast of the high aluminum bauxite in refractory material industry, roast of clinker and aluminum hydroxide in aluminum manufacturer, and roast of the chromium ore and chromium powder in chemical industry. The lime kiln is mainly used for roasting the active lime and light roasting of the dolomite in ironworks and ferroalloy works.

Working Principle of Rotary Kiln:

The rotary kiln is made up of gas flow, fuel burning, heat transfer, and material movement etc process. The rotary kiln is to make the fuel fully burning, the heat from which can be effectively pass to materials, so that material can produce series of physical and chemical changes after receiving the heat, finally forming finished product chamotte.

Cement kiln, Rotary kiln Applications:

1) Rotary kiln is the key equipment in cement industry for calcining clinker.

2) It is also used in various industries, such as metallurgy, chemistry, building, refractory material, environmental protection, etc.

3) The kiln is composed of the cylindrical shell, roller supporting device with thrust roller, driving gear unit movable kiln hood, sealing device at kiln inlet, coal dust pipe device etc.

Cement kiln, Rotary kiln Working Principle:

1) With a certain slope to the level, the whole kiln body is supported by rollers and fitted with thrust rollers to control up and down movement of the kiln body.

2) Besides main driving unit for driving system, it is also fitted with the auxiliary driving unit so as to ensure the kiln body still can rotating when the main motor is powered off and prevent it from deforming.

3) The kiln head adopts housing type sealing and kiln rear uses axial contact sealing unit so that reliability of sealing could be ensured.

Parameters:

Spec.(m) | Φ2.8/2.5×44 | Φ3×48 | Φ3.2×50 | Φ3.3×50 | Φ3.5×54 | Φ4×60 | ||

Capacity(t/d) | 300 | 600-700 | 1000 | 1200 | 1500-1800 | 2500 | ||

Slope of the kiln shell (%) | 3.5 | 3.5 | 3.5 | 4 | 4 | 4 | ||

Support Qty | 3 | 3 | 3 | 3 | 3 | 3 | ||

Type of thrust roller | Mechanical | Mechanical | Mechanical | Mechanical | Mechanical | Hydraulic | ||

Auxiliary driving | Electrical motor

| Type | Y122M-4 | Y160M-6 | Y160M-4B | Y160M-4 | Y200L1-6 | Y180L-4 |

Rated Power (kw) | 4 | 7.5 | 15 | 11 | 18.5 | 22 | ||

Rated speed (r/min) | 1440 | 970 | 1460 | 1460 | 970 | 1470 | ||

Rated voltage (v) | 380 | 380 | 380 | 380 | 380 | 380 | ||

Reducer | Model | ZL35-16 | ZL35-7-1 | ZSY160-31.5 | ZSY355-31.5 | ZSY355 | YNS440-45R | |

Total ratio | 40.44 | 14 | 31.5 | 31.5 | 45 | 45 | ||

Total weight (excluding refractory brick) (ton)

| 177 | 207 | 256.5 | 281 | 341 | 434 | ||

Weight of discharging kiln hood (ton) | 20 | 22 | 25 | 27 | 28 | 35 | ||

Structure of Rotary Kiln:

The equipment is composed of cylinder, supporting device, supporting device with catch wheel, transmission device, active kiln head, kiln end sealing device, burning device etc components. The rotary kiln is featured by simple structure, reliable operation, and easy control in production process etc. The rotary kiln produced by Zhongke has the calcining system equipment through technology innovation, which adopts the most advanced hydraulic catch wheel, high precision of measurement piston pump, flow speed control valve, and contact graphite piece of sealing device at home and abroad, In order to improve the degree of automation, kiln head adopts industrial TV watching fire, analog fluorescent screen for process flow, and calcination zone adopts the infrared scanner, directly reflecting the calcination situation in computer.

Company proflile

Henan Kuangyan Heavy Machinery Co., Ltd. is specialized in heavy equipment like various crushers, magnetic separators, mining machines, bricks and blocks machines, cement production line, AAC block line, etc., which is located in the middle of China. Our competitive price, high quality products and excellent after-sales service had gain us good reputation in this field.

Our company is headquartered in Zhengzhou Country's High-tech Industrial Development Zone, which consists of three branches, a research and development department. Since the establishment of the company, always adopt advanced modern management system, and focused on innovation, has brought together a number of scientific and technological elite, the company employees is more than 500people now, with 20 senior engineers, and more than 100 midding technicians. The company has long-term cooperation with domestic scientific research units, has introduced advanced technology, technics and testing system at home and abroad.

Our service:

1. Pre-sales services:

1) Select proper equipment model;

2) Design and manufacture products according to clients' special requirement;

3) Arrange for visiting our factory, assist them to handle relative procedure, such as visa.

2. Services during the sale:

1) Make sure goods prepared within delivery time;

2) Pre-check and accept products ahead of delivery;

3) Prepare documents required to help customer pass customs clearance;

4) Help clients to make Project evaluation and feasibility analysis and draft solving plans.

3. After-sales services:

1) Assist clients to prepare for the first construction scheme;

2) Install, debug and examine the equipment;

3) Train technical personnel the first-line operators;

4) Provide technical exchanging;

5) Offer spare parts at a best price for long term.

Note: Responsible for handling other required matters conforming the state regulations