Hot selling excellent high quality jaw crusher machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | EXW |

| Payment Terms: | T/T |

| Supply Ability: | 65 sets per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Stone Crusher, Ball Mill, Magnetic Separator |

Product Detail

| Model No.: | PE150*250 |

|---|---|

| Application: | Ore |

| Type: | Crusher |

| Feed opening size: | 150mm*250mm |

| Production Capacity: | 65 sets per month |

| Packing: | international standard export packing |

| Delivery Date: | 25 days after recieve deposite payment |

Product Description

.Introduction to PE&PEX small jaw crusher /stone jaw crusher for sale Features

1. Our jaw crusher imitates animals' jaw movement to crush stones, which is widely applied in medium-level granularity crushing, of various ores and chunks of materials in the mine industry.

2. The highest compressive strength of stone crushing is 320Mpa and jaw crusher is the most widely-used crushing equipment at present.

Jaw crusher information

1,jaw crusher product is applicable for crushing various materials with compression strength

less than 320Mpa in the fields of metallurgy, mine,building materials...etc.

2,jaw crusher machine has an unique performance advantages which make it not only rubble,

but also to a certain extent, truly perfect that the resistance abrasion and discharging is fine,today

the jaw crusher is the one of most ideal equipment for minging broken.

3,The compressive resistance of the materials to be crushers is up to 320Mpa.The large and medium

sized crushers are the key products in our company and stand in the front of the industry in the aspects

of design and production.

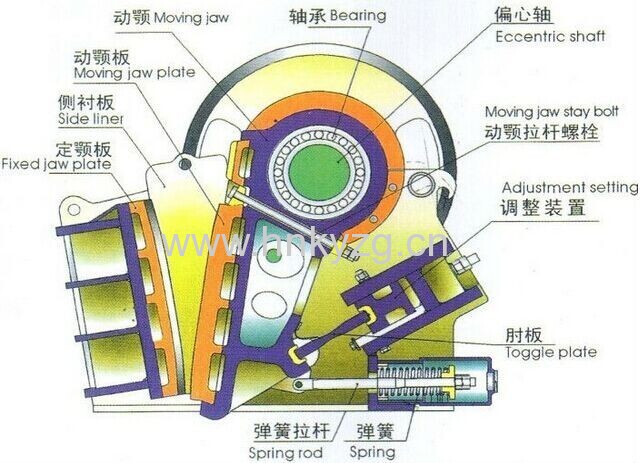

Working principle of jaw crusher

When the jaw crusher working,The motor drive the belt wheel ,and makes movable jaw move up and

down by eccentric shaft.When the movable jaw down, the angle between the fixed jaw and movable jaw

becomes small,and the materials can be crushers to reach the crushing target.When the movable jaw

rises,the angle between the fixed jaw and movable jaw gets larger.The movable jaw plate leave the fixed

jaw plate under the function of drawbar and spring,and then the crushed materials are discharges from

outlet of the crushing cavity.

Points for attention of jaw crusher

1), Feeding material when the jaw crusher runs regularly.

2), To avoid withstand loading or single-side overloading, should evenly feed the processing material.

3), When running regularly, the temperature rising of bearing should not exceed 30°C, and the Max.

temperature is should not exceed 70°C. Stop at once when exceeding the above temperature to find

the cause and settle it.

4), Should stop feeding at first before parking,after the material in crushing cavity were discharged, could

shut off the power.

5), Should shut off the power when crushing the material and blocking in crushing cavity causing parking.

After getting cleaning, could start again.

6), Could turn around the plate when one side is wear out.

7), Should reinforce the lining regularly.

Delivery

Company profile

Henan Kuangyan Heavy Machinery Co., Ltd. is specialized in heavy equipment like various crushers, magnetic separators, mining machines, bricks and blocks machines, cement production line, AAC block line, etc., which is located in the middle of China. Our competitive price, high quality products and excellent after-sales service had gain us good reputation in this field.

Qualification

International Cooperation

Our Service

1. Pre-sales services:

1) Select proper equipment model;

2) Design and manufacture products according to clients' special requirement;

3) Arrange for visiting our factory, assist them to handle relative procedure, such as visa.

2. Services during the sale:

1) Make sure goods prepared within delivery time;

2) Pre-check and accept products ahead of delivery;

3) Prepare documents required to help customer pass customs clearance;

4) Help clients to make Project evaluation and feasibility analysis and draft solving plans.

3. After-sales services:

1) Assist clients to prepare for the first construction scheme;

2) Install, debug and examine the equipment;

3) Train technical personnel the first-line operators;

4) Provide technical exchanging;

5) Offer spare parts at a best price for long term.

Related product

Trommel screen

Claasifier