China Coarse Primary Stone Jaw Crusher for Stone Quarry Plant

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | EXW |

| Payment Terms: | T/T |

| Supply Ability: | 60 sets per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Stone Crusher, Ball Mill, Magnetic Separator |

Product Detail

| Model No.: | PE-1200*1500 |

|---|---|

| Means of Transport: | Ocean |

| Application: | Ore |

| Type: | Crusher |

| Brand Name: | Kuangyan |

| Feed opening size: | 1200mm*1500mm |

| Max feed size: | 1020mm |

| Discharge size: | 150-300mm |

| Capacity: | 400-800t/h |

| Rotate speed of eccentric shaft: | 180r/min |

| Weight: | 100.9t |

| Overall dimension: | 4200mm*3300mm*3500mm |

| Condition: | new |

| Warranty: | 12 month |

| Voltage: | 380v |

| Production Capacity: | 60 sets per month |

| Packing: | International standard export packing |

| Delivery Date: | 20 days after recieve deposite payment |

Product Description

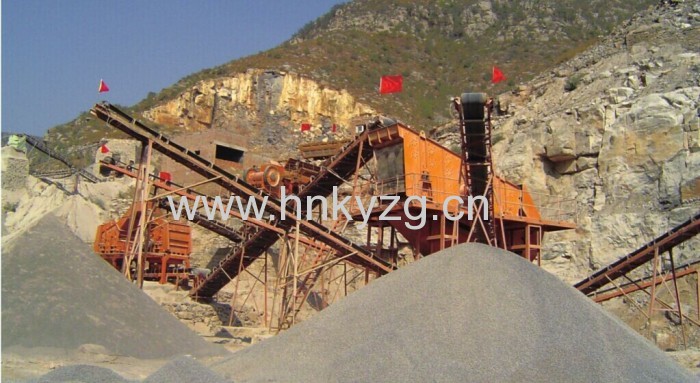

Stone Jaw Crusher for Stone Quarry Plant

Primary stone jaw crusher is typically of the square opening design, and secondary jaw crusher is of the rectangular opening design. Jaw Crusher reduces large size rocks or ore by placing the rock into compression. A fixed jaw board, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the stationary plate. The spaces at the bottom of the "V" aligned jaw plates decide the crusher product size gap, or the size of the crushed product from the jaw crusher. The rock remains in the jaw until it is small enough to pass through the gap at the bottom of the jaws.

Features of Stone Jaw Crusher for Stone Quarry Plant

1.Deep crushing cavity and no dead time control have improved the feeding capability and the production output .

2.Large crushing ratio and even particle size.

3.Gasket discharge opening adjustment equipment makes the function more reliable and convenient , adjustment more large ,and the equipment more flexible .

4.The lubrication system more secure and reliable ,the spare parts can be more changed ,and low maintenance working.

5.Simple structure and relable function,low operation cost.

6.Energy-saving : the single machine can make the energy-saving about 15%~30% and the system energy-saving over one time.

7.Large range of the discharge opening range can satisfy the various requirements of the customers . 8.Low noise and dust pollution.

Working priciple of Stone Jaw Crusher for Stone Quarry Plant

The motor transmits power through belt, drives the moving jaw do periodic motion to the fixed jaw surround the eccentric shaft. The angle between toggle plate and moving jaw increases when moving jaw moves up. So the moving jaw closes to the fixed jaw. The stuff will be crushed in this process. The angle of Jaw Crusher between toggle plate and moving jaw decreases when moving jaw moves down, the moving jaw of Jaw Crusher moves away from fixed jaw by the pulling of rod and spring, the products after crushing will be discharged from the outlet of Jaw Crusher.

Stone Jaw Crusher for Stone Quarry Plant main technical parameters

Model | Feed opening size(mm) | Max feed size(mm) | Discharge size(mm) | Capacity(t/h) | Rotary speed of eccentric shaft(r/min) | Power(kw) | Weight(t) | Overall dimension(mm) |

PE-150*250 | 150*250 | 125 | 10-40 | 1-3 | 250 | 5.5 | 0.8 | 720*660*850 |

PE-200*300 | 200*300 | 180 | 15-50 | 2-6 | 260 | 7.5 | 1.2 | 910*750*990 |

PE-200*350 | 200*350 | 180 | 18-70 | 3-10 | 260 | 11 | 1.5 | 1000*870*990 |

PE-250*400 | 250*400 | 210 | 20-60 | 5-20 | 300 | 15 | 2.8 | 1300*1090*1270 |

PE-400*600 | 400*600 | 340 | 40-100 | 16-60 | 275 | 30 | 7 | 1730*1730*1630 |

PE-500*750 | 500*750 | 425 | 50-100 | 40-110 | 275 | 55 | 12 | 1980*2080*1870 |

PE-600*900 | 600*900 | 500 | 65-160 | 50-180 | 250 | 75 | 17 | 2190*2206*2300 |

PE-750*1060 | 750*1060 | 630 | 80-140 | 110-320 | 250 | 90 | 29 | 2660*2430*2800 |

PE-900*1200 | 900*1200 | 750 | 95-165 | 220-450 | 200 | 110 | 52 | 3380*2870*3330 |

PE-1000*1200 | 1000*1200 | 850 | 195-265 | 315-500 | 200 | 110 | 55 | 3480*2876*3330 |

PE-1200*1500 | 1200*1500 | 1020 | 150-300 | 400-800 | 180 | 160 | 100.6 | 4200*3300*3500 |

PEX-150*750 | 150*750 | 120 | 18-48 | 8-25 | 320 | 15 | 3.8 | 1200*1530*1060 |

PEX-250*750 | 250*750 | 210 | 25-60 | 13-35 | 330 | 30 | 5.5 | 1830*1750*1540 |

PEX-250*1000 | 250*1000 | 210 | 5-60 | 16-52 | 330 | 30 | 7 | 1560*1950*1390 |

PEX-250*1200 | 250*1200 | 210 | 25-60 | 20-61 | 330 | 37 | 9.7 | 2140*1660*1500 |

PEX-300*1300 | 300*1300 | 250 | 20-90 | 20-105 | 300 | 55 | 15.6 | 2720*1950*1600 |

Application of Stone Jaw Crusher for Stone Quarry Plant

It's mainly applicable to varioid ore and big block primary crushing, widely used in mining, quaay, metallurgy buillding materials highway railway construction waster processing waster processing water conservancy and chemical industru etc. The max compression resistant of curhsed material is 320Mpa.

Company profile

Hena Kuangyan Machinery Co.,Ltd which is the branch of Henan Zhongke Engineering & Technology Co,. Ltd, are professional manufacturer which specialized in heavy equipment development and production. Our main products include mining equipment, ore dressing equipment, building material making equipment, such as various crushers, ball mill, magnetic separators, floation machine, rotary dryer, rotary kiln, cooling machine, bricks and blocks machines, cement and lime production line, AAC block line, ceramic sand production line, stone and sand production line etc., Our factory is located in the middle of China, Henan province, the base of china heavy equipment. We have more than 40 years experience in this field. Our high quality products, competitive price and excellent after-sales service had gained us good reputation in this field. We have brought together a number of scientific and technological elite. More than 500 employee in our factory with 20 senior engineers and more than 100 middling technicians. We have strong technical and resources support behind us.

Qualification of Henan Kuangyan

International cooperation

Our service

1. Pre-sales services:

1) Select proper equipment model;

2) Design and manufacture products according to clients' special requirement;

3) Arrange for visiting our factory, assist them to handle relative procedure, such as visa.

2. Services during the sale:

1) Make sure goods prepared within delivery time;

2) Pre-check and accept products ahead of delivery;

3) Prepare documents required to help customer pass customs clearance;

4) Help clients to make Project evaluation and feasibility analysis and draft solving plans.

3. After-sales services:

1) Assist clients to prepare for the first construction scheme;

2) Install, debug and examine the equipment;

3) Train technical personnel the first-line operators;

4) Provide technical exchanging;

5) Offer spare parts at a best price for long term.

Note: Responsible for handling other required matters conforming the state regulations.

If you are interested in oou product, please contact us!

Fax: +86 0371 6756 0033 Phone: +86 0371 6756 0055