Rotary drum dryer for drying clay for cement plant

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 20 sets/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Stone Crusher, Ball Mill, Magnetic Separator |

Product Detail

| Model No.: | ZT-2.8*20 |

|---|---|

| Means of Transport: | Ocean |

| Application: | Coal |

| Type: | Others |

| Brand Name: | Kuangyan |

| Inside dia.: | 2.8 m |

| Length: | 20 m |

| Gradient: | 4.0% |

| Rotate speed: | 3.7 r/min |

| Power: | 40kw |

| Capacity: | 45-55 t/h |

| Weight: | 71/75 t |

| warranty: | one year |

| Installation: | under our engineer's guidence |

| certification: | ISO:9001-2008,CQC,BV,CE |

| Production Capacity: | 20 sets/month |

| Packing: | international standard packing |

| Delivery Date: | 20-25 days after receiving the prepayment |

Product Description

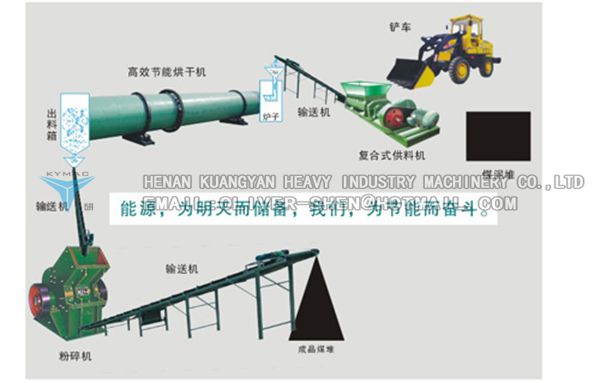

Rotary drum dryer for drying clay for cement plant

Introduction of Rotary Dryer:

Rotary dryer is mainly used in construction,metallurgy,chemistry,cement industries for drying slag,clay and so on. The rotary drier is made up of the rotary shell, lifting plate, driving device, supporting device and sealing ring. The rotary drier have the advantage of reasonable design,best fabric,high capacity,lower in energy consumption and easy to control.

Working principle of Rotary Dryer:

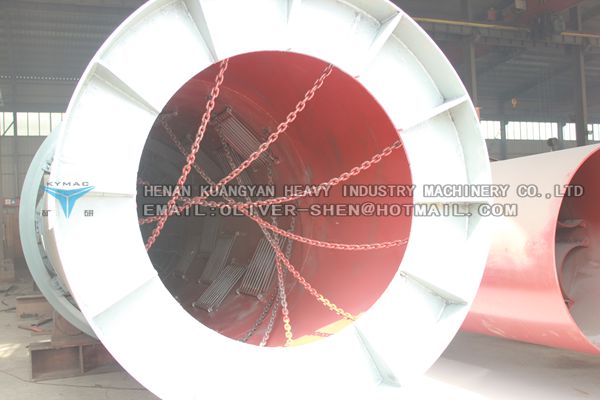

Wet materials is carried to hopper by belt conveyor or bucket elevator, and added in from the top of feed opening. The cylinder is the main body of the dryer, the material through internal cylinder will contact with the hot air through it in the form of direct flow or reverse flow, or make an efficient contact with the heated wall surface and be dried. After drying, the products will be discharged from the bottom of the other end. In the course of the drying, the materials will move from higher end to lower end in the action of gravity with the help of the slow turning of the cylinder. The cylinder wall is equipped with downstream shovelling plate, which constantly lift the materials and sprinkling it down, so that the heat contact surface of materials is greatly enhanced, improving the drying speed and driving the materials to move ahead. After heat carrier (hot air, flue gas) drying material, the waste gas is evacuated after the carried dust is collected by the cyclone dust collectors. Rotary dryer is one of the oldest and mature drying equipment. The diameter and length of the cylinder is determined by the technological conditions, the size of which reflects the production capacity. The load of the cylinder is mainly determined by self weight of cylinder, the quality of the lining and materials etc.

Features of Rotary dryer compare with other dryer:

1,Large production capability, continuous operation

2,Simple structure, convenient operation

3,Low malfunction, low maintenance cost

4,Wide scope of application, can be used to dry the granular materials, favorable for those materials with the big adhesion

5,Great operating flexibility, the output of the products allows a larger fluctuation range, not influencing the quality of the products

Application range of Rotary dryer:

1, Chemical industry: ammonium sulfate, sodium sulphide, ammophos, ammonium nitrate, carbamide, oxalic acid, potassium dichromate, PVC, nitrophosphate fertilizer, calcium magnesium phosphate, compound fertilizer

2, Food industry: Glucose, salt, granulated sugar, vitamin malted milk, Granular sugar

3, Minerals: Bentonite, Titanium concentrate, coal, manganese ore, pyrite, limestone, peat

4, Others: Iron powder, flat soybean, garbage abrasive, match sticks, wood chips, vinasse

The technical parameters of Rotary dryer:

| model | technical parameter of barrel | power (kw) | capacity (t/h) | weight (kg) | |||

| inside dia.(m) | length (m) | gradient (%) | rotate speed (r/min) | ||||

| ZT-1.2*6.0/8 | 1.2 | 6/8 | 5.0 | 5.8 | 5.5 | 8-12 | 9380/10200 |

| ZT-1.5*12/15 | 1.5 | 12/15 | 5.0 | 4.8 | 15 | 12-16 | 16450/18240 |

| ZT-1.8*12/14 | 1.8 | 12/14 | 5.0 | 4.5 | 18.5 | 18-20 | 20000/21000 |

| ZT-2.2*12/14 | 2.2 | 12/14 | 5.0 | 4.3 | 22 | 22-28 | 37100/38830 |

| ZT-2.4*14 | 2.4 | 14 | 4.0 | 3.78 | 30 | 30-35 | 50700 |

| ZT-2.4*18 | 2.4 | 18 | 4.0 | 3.0 | 37 | 35-40 | 54000 |

| ZT-2.4*22 | 2.4 | 22 | 3.0 | 3.0 | 45 | 38-42 | 57000 |

| ZT-2.8*20 | 2.8 | 20 | 4.0 | 3.7 | 40 | 45-55 | 71000/75000 |

| ZT-3.0*22/25 | 3.0 | 22/25 | 4.0 | 3.2 | 75 | 58-70 | 88000/95000 |

| ZT-3.2*25 | 3.2 | 25 | 4.0 | 3.0 | 110 | 75-90 | 166000 |

| ZT-3.6*25 | 3.6 | 25 | 4.0 | 2.7 | 132 | 95-110 | 188000 |

Company Description

Henan Kuangyan Heavy Industry Machinery Co., Ltd. is a joint-stock enterprise which produces large-sized and medium-sized crushers and mills, mining equipments, and light AAC brick/block making machines.

Under such circumstances, we make full use of the good opportunity and try our best to have a great progress in technical transformation, innovation, improving the quality of products, and continuously expanding the domestic and overseas markets. Through years of development, our products have gained a favorable comment from markets all over the world. As the leading company in crushing & milling fields, we have developed series of newly-designed crushers by absorbing advanced scientific technology & processing experience from abroad and our experts' continuous research. It has been proved that our crushing products have covered a good market share both in domestic and overseas for high quality & easy maintenance.

Certificates

Workshop

Delivery

International Cooperation

It's our mission to provide superior service for you!

1. Pre-sale services:

Act as a good adviser and assistant of clients, enable them to get rich and generous returns on their investments.

1>. Select equipment model;

2>. Design and manufacture products according to clients' special requirement;

3>. Train technical personnel for clients.

2. Services during the sale:

Respect clients, devote ourselves to improving the total value of clients.

1>. Pre-check and accept products ahead of delivery;

2>. Help clients to draft solving plans.

3. After-sale services:

Provide considerate services to minimize clients' worries.

1>. Assist clients to prepare for the first construction scheme;

2>. Install and debug the equipment;

3>. Train the first-line operators;

4>. Examine the equipment;

5>. Take initiative to eliminate the troubles rapidly;

6>. Provide perfect service;

7>. Provide technical exchanges.