Duplex steel F904L blind flange

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 30 tons per month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Stainless Steel Flanges, Carbon Steel Blind Flange, Forged Stainless Steel Weld Neck Flange, Galvanized Plate Flanges With Flat Face, Stainless Steel Lap Joint Flange |

Product Detail

| Model No.: | BLRF |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Technics: | Forged |

| Type: | Flange |

| Brand Name: | GS |

| Material: | duplex steel F904L |

| Standard: | ANSI/ASME B16.5, ANSI/ASME B16.47, EN1092-1, JIS B2220 |

| Pressure: | 150,300,600,900,1500,2500 |

| Size: | 1/2inch-48inch |

| Production Capacity: | 30 tons per month |

| Packing: | plywood case |

| Delivery Date: | 15 days |

Product Description

Duplex steel F904L blind flange

| Product description | |||||

| Duplex steel F904L blind flanges | |||||

| Standard | ANSI/ASME B16.5, ANSI/ASME B16.47, EN1092-1, JIS B2220, GB/T 9112, HG 20592 | ||||

| Type | blind cover flange | ||||

| Norminal pressure | 150lb, 300lb, 600lb, 900lb, 1500lb, 2500lb | ||||

| PN6, PN10, PN16, PN25, PN40, PN61 | |||||

| 5K, 10K, 16K, 20K | |||||

| Norminal size | 1/2inch-48inch | ||||

| DN15-DN1200 | |||||

| 15A-1200A | |||||

| Material | ASTM A182 F904L | ||||

| Flange face | FF, RF, RTJ, TF, GF,MF | ||||

| Brand | GS | ||||

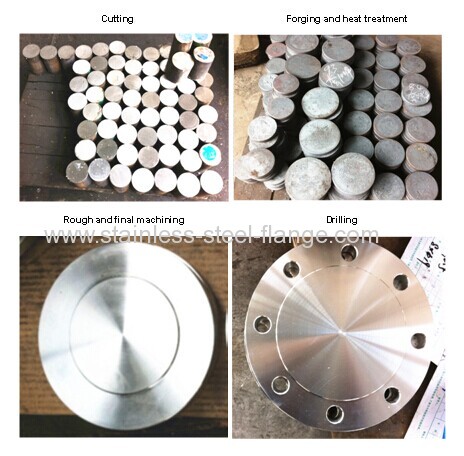

| Technology | by forging | ||||

| Raw material | ingot, bar or billet | ||||

| Certificate | MTC or EN10204 3.1 as per NACE MR0175 | ||||

| Quality system | ISO9001; PED 97/23/EC | ||||

| Lead time | 15-30 days depending on quantity | ||||

| Payment term | T/T, L/C, D/P | ||||

| Origin | Jiangyin, China | ||||

| Loading port | Shanghai, China | ||||

| Package | suitable for seaway transportation, ply wooden case with plastic film sealed | ||||

| MOQ | 1 ton | ||||

| Chemical Composition: | ||||||||

| Grade | C Max % | Mn Max % | P Max % | S Max % | Si Max % | Ni Max % | Cr Max % | Mo Max % |

| F904L | 0.02 | 2.0 | 0.04 | 0.03 | 1.0 | 23.0-28.0 | 19.0-23.0 | 4.0-5.0 |

| Mechanical Property: | ||||||||

| Grade | Tensile Strength Min Mpa | Yield Strength Min Mpa | Elongation Min % | Reduction Min % | HBW | |||

| F904L | 490 | 215 | 35 | |||||

Drawing:

Manufacture process:

About us: