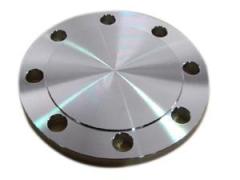

Tongue face and groove face blind flange

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 50 tons per month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Stainless Steel Flanges, Carbon Steel Blind Flange, Forged Stainless Steel Weld Neck Flange, Galvanized Plate Flanges With Flat Face, Stainless Steel Lap Joint Flange |

Product Detail

| Model No.: | BLTF |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | GS |

| Standard: | ANSI B16.5 |

| Pressure: | 150,300,600,900,1500 |

| Size: | 1/2inch-24inch |

| Material: | A182 F304L, F316L, F321, F347 |

| Flange face: | tongue face and groove face |

| Production Capacity: | 50 tons per month |

| Packing: | plywooden case |

| Delivery Date: | 15-25 days |

Product Description

Tongue face and groove face blind flange

| Product description | |||||

| Tongue face and groove face blind flange | |||||

| Standard | ANSI/ASME B16.5 | ||||

| Type | blind cover flange | ||||

| Norminal pressure | 150lb, 300lb, 600lb, 900lb, 1500lb, 2500lb | ||||

| Norminal size | 1/2inch-24inch | ||||

| Material | ASTM A182 F316Ti | ||||

| Seal face | tongue face and groove face | ||||

| Brand | GS | ||||

| Technology | by forging | ||||

| Raw material | ingot, bar or billet | ||||

| Certificate | MTC or EN10204 3.1 as per NACE MR0175 | ||||

| Quality system | ISO9001; PED 97/23/EC | ||||

| Lead time | 15-30 days depending on quantity | ||||

| Payment term | T/T, L/C, D/P | ||||

| Origin | Jiangyin, China | ||||

| Loading port | Shanghai, China | ||||

| Package | suitable for seaway transportation, ply wooden case with plastic film sealed | ||||

| MOQ | 1 ton | ||||

Tongue Face

The Tongue and Groove faces of this flanges must be matched. One flange face has a raised ring (Tongue) machined onto the flange face while the mating flange has a matching depression (Groove) machined into it's face.

Tongue-and-groove facings are standardized in both large and small types. They differ from male-and-female in that the inside diameters of the tongue-and-groove do not extend into the flange base, thus retaining the gasket on its inner and outer diameter. These are commonly found on pump covers and Valve Bonnets.

Tongue-and-groove joints also have an advantage in that they are self-aligning and act as a reservoir for the adhesive. The scarf joint keeps the axis of loading in line with the joint and does not require a major machining operation.

Product:

About us: