Wood Plastic Profile Extrusion Line , Conical Twin Screw Extruder

| Place of Origin: | Shandong |

|---|

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Plastic Extrusion Line (15), Plastic Pipe Extrusion Line (21), Plastic Sheet Extrusion Line (9) |

Product Detail

| Model No.: | SJSZ65/132 |

|---|

Product Description

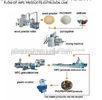

Wood Plastic Profile Extrusion Line , Conical Twin Screw Extruder

Quick detail:

1. field:outdoors landscapes,garden decoration,construction,flower box board,sign

board,corridor,terrace,parking room,railway slippers,automobile inner decoration,Vehicle components,

Industrial and civilian consumer goods,

2. product:pallet,fence,window and door frame, furniture,deck,railing,chair,tray,ceiling,plank,bench,trash

box,handrail,building template,

3. process type:extruding machine

4.feature:fire protection,moistureproof,water resistant,insect resistant.

5.screw design:double screw

6.environmental product

7.raw material:wood powder with PE/PP,PP/PE can be recycled

8.port:Qingdao port

9.wood powder: sawdust, saw powder, straw, wheat bran, rice husk

10.certification:CE,CSA,UL,ISO9001

11.documents:commercial invoice,packing list,certificate of original,bill of lading,quality certificate,form

E,form A,etc

12.type:WPC profile extrusion line,wood plastic composite profile extrusion machinery

13.screw type:double conical screw.

14.output:160-280kg/h

15.component:1).Automatic feeder,2).SJSZ65/132 Conical Twin Screw Extruder,3).SZD-4000 Vacuum sizing

table,4).SQY-240 hauling-off machine,5).SQG-240 cutting machine,6).SFZ-6000 stacker

16.application:wood plastic composit profile

17.voltage:380V/3P/50HZ,600V/3P/60HZ,220V/3P/60HZ,or according to customer’s requirement.

18. After-sales Service Provided: Engineers available to service machinery overseas

19.mold:change molds to produce different profile products.

21.Minimum order:one set

22.application area:packaging,decoration,construction,logistics,gardens,municipal

administration,traffic,sports,environmental protection,military,home furnishing,children’s toys

23.wpc product type:hollow and solid

24.auxiliary machine:emboss machine,sanding machine,brushing machine,etc

Description:

1.PE WPC floor profile is special for outdoor. This machine uses the special designed screw and barrel, die

and extrusion process to produce plastic and wood products.

2.The series of products are: One step thick plastic and wood plate extrusion machine, one step plastic and

wood profile extrusion machine, one step plastic and wood decoration plate extrusion machine, plastic and

wood pelletizing machine and different kinds of plastic and wood dies.

3.This machine can use the one step extrusion method and also it can use the two-step extrusion method

after pelletizing. The two-step extrusion method can save the power and space, and the two-step extrusion

method features the machine can gain the high output and stable extrusion pressure.

4.A pre-heating feeder is mounted on the top of the extruder which extracts the humidity from the wood

powder, so that the feeding section of the extruder can be filled with enough material and the plastification

effect will be better.

5.Special and well designed screw enables the raw material to be evenly stay in the extruder. The screws

and barrel are bi-metallic treated, more wearable and anti-corrosion.

6.The machine can produce PE, PP or PVC and wood profile products. These products are mainly applied

for making pallets, packing cases, floors, wall decoration materials and other wide applications. The wood

powder or plant fiber can be put up to max. 50-75%. This machine can produce the PP, PE, PVC, ABS, PS

and etc

Applications:

1.field:outdoor,building,logistic,car,garden,home decoration,

2.product:plank floor,pavilion,chair,door,building template,tray,rail crosstie,fence,courtyard handrail,flower

pot.

3.decoration

You Might Also Like