C/Z Purlin Roll Forming Machine is fully-automatically controlled by PLC. Compared with other type C/Z purlin machine, it's reliable for running steadily, punching hole in a highly precision, high output and inerratic and smooth surface of the notch.

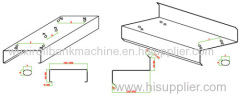

Producing Process Sketch of Pre-punching / Pre-cutting C/Z Purlin Roll Forming Machine:

Technological Process of Pre-punching / Pre-cutting C/Z Purlin Roll Forming Machine:

Uncoiling—Feeding—Leveling—Pre-punching &Pre-cutting—Roll forming—Products collecting

Main Technical Specifications of Pre-punching / Pre-cutting C/Z Purlin Roll Forming Machine:

| Number | Items | UnitType | RF-CP-1 | RF-ZP-1 |

| 1 | Purlin specification | mm | 80-300 | 100-300 |

| 2 | Steel Thickness | mm | 2.0-3.0 | 2.0-3.0 |

| 3 | Forming Speed | m/min | 10-15 | 10-15 |

| 4 | Roller stands | stand | 18 | 20 |

| 5 | Material of roller |

| 45# steel, coated with chrome | 45# steel, coated with chrome |

| 6 | Main Motor Power | Kw | 15 | 18 |

| 7 | Hydraulic Power | Kw | 11 | 11 |

| 8 | Hydraulic pressure Mpa | Mpa | 20 | 20 |

| 9 | Power Supply |

| 380V, 50HZ,3 phase | 380V, 50HZ,3 phase |

| 10 | Tolerance | mm | 1.5 | 1.5 |

| 11 | Material of cutting |

| Cr12 | Cr12 |

| 12 | Control system |

| PLC with touch screen | PLC with touch screen |

| 13 | Machine net weight | T | 14 | 15 |