high quality waterproof phenolic film faced plywood for construction

| Min. Order: | 1 40HQ container |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 60HQ containers per month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Linyi, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Film: | phenolic, Made in China, imported Dynea |

| Film density: | 120, 240 |

| Core: | poplar, hardwood, birch, combi |

| Core style: | whole-piece, finger-joint |

| Glue: | MR, WBP melamine, WBP phenolic, imported phenolic |

| Edges: | sealed by waterproof painting |

| Hot primess: | one time, two times |

| Cold press: | one time |

| Sanding: | one side, two sides |

| Color: | black, brown, red, yellow, etc |

| Production Capacity: | 60HQ containers per month |

| Packing: | standard export pallet packing |

| Delivery Date: | within 15 days for standard size |

Product Description

Specification

| Product name | film faced plywood |

| Usage | construction, such as concrete formwork |

| Size | 1220x2440mm, 1250x2500mm, etc |

| Thickness | 12mm, 15mm, 18mm, 21mm, etc |

| Thickness tolerance | ±0.50mm |

| Number of plies | 7, 9, 11, 13, etc |

| Film | black film, brown film, imported Dynea brown film |

| Film finish | smooth, anti-slip/wiremeshed |

| Core | poplar, hardwood, birch, combi, etc |

| Glue | MR, Melamine, WBP phenolic (24h, 48h, 72h) |

| Edges | waterproof painting |

| Hot press | one time, two times |

| Sanding | one side, both sides |

| Reuse times | 3-5 times, 8-12 times, 15-20 times, 30times |

Product show

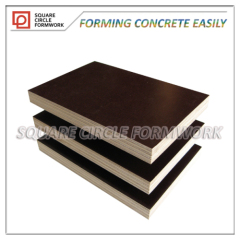

1. Black film faced plywood

2. Brown film faced plywood

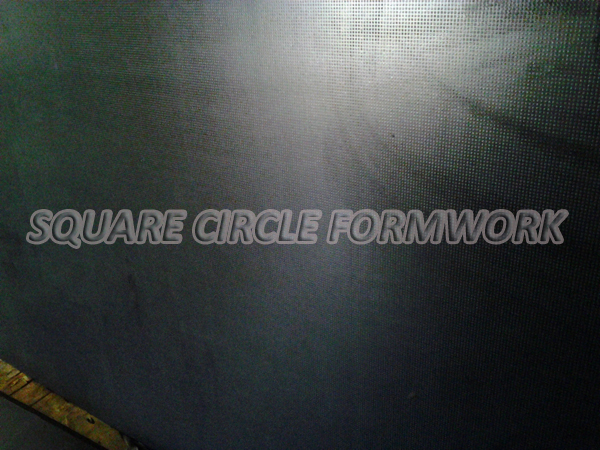

3. Anti-slip or wiremeshed film faced plywood

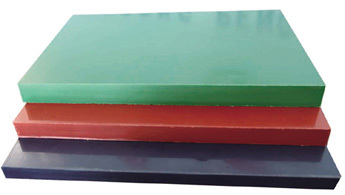

4. Red film faced plywood

5. Film faced plywood edges with waterproof painting

6. Film faced plywood with logo

7. High quality film faced plywood with whole-piece core

8. Cheap film faced plywood with finger-joint core

Application on site

From feedback on site, the film faced plywood have a different quality. The cheap one with finger-joint core is only reused 3 times more or less, the better one with birch whole-piece core can be reused 15 times at least. If it's used in metal frame as formwork panel, it plus 100 times at least. Besides, the concrete release agent need to be painted before usage, which make the dismantling quickly and supply a nice concrete finish.

Packing details

standard export pallet packing, inside packing by waterproof plastic bag and hard corrugated paper board in corners, outside packing by carton and steel strips

Related product

PP Plastic Plywood Column Formwork Circular Column Formwork

Contact us