wooden circular column formwork for construction

| Min. Order: | 1 twenty-foot container |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, it is negotiable, T/T |

| Supply Ability: | 50,000 sqm per month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Linyi, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | sc-4 |

|---|---|

| Means of Transport: | Ocean |

| origin: | China |

| inner material: | poplor |

| glue: | WBP phenolic |

| film: | epoxy resin |

| air permeability: | good |

| resuable: | 6-10 time |

| weight: | light |

| apperance: | nice finish |

| thickness: | 15, 18 or request |

| size: | 300-2200mm At 50mm intervals |

| Production Capacity: | 50,000 sqm per month |

| Packing: | Packing method is subject to specific requirements from customers |

| Delivery Date: | within 25 days after deposit |

Product Description

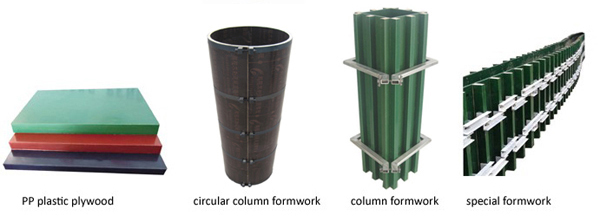

round column formwork made of wood,wooden circular column formwork for construction

Product Composition

Circular column formwork | Film faced plywood | Core | poplar |

Glue | WBP melamine | ||

Film | Brown film | ||

Hot press | twice | ||

sanding | Both sides | ||

Edges | With grooves | ||

Steel belts | Steel no. | Q235 | |

width | 32mm | ||

thickness | 1.2mm | ||

screws | item | 8.8 grade M12 | |

size | 12x80mm |

Advantages

1. Made of plywood, light weight, easy handling

2. Grooves prevent the leakage of concrete

3. Easy cutting

3. Easy cutting

4. Efficient installation and dismantling

5. Nice concrete finish without re-work

Product options

Inner Diameter | Thickness | Height | Parts |

300-500mm At 50mm intervals | 15mm (3/5") | 2000mm / 2400mm | 2 |

600-1250mm At 50mm intervals | 18mm (3/4") | 2000mm / 2400mm | 2 |

1300-1500mm At 100mm intervals | 21mm (7/8") | 2000mm / 2400mm | 2 |

1600-2200mm At 100mm intervals | 21mm (7/8") | 2000mm / 2400mm | 4-6 |

Comparison

Circular column formwork | Steel circular column formwork | |

picture | ||

Weight | Light Less likely to need a crane | Heavy Need a crane and more workers |

Cutting | Easy cutting | Difficult cutting |

Installation & Dismantling | Two workers can install 15 columns in 8 hours. The ply panel will separate easily | More workers and cranes |

Concrete finish | Nice concrete finish without re-work | Obvious bubbles |

Technical data

Testing items | Unit | Standard used | Tested value | |

Bonding quality | N/mm² | EN314 | 0.81 | |

Bending strength | Longitudinal grain | N/mm² | EN310 | 50.0 |

Cross grain | N/mm² | 40.2 | ||

Elasticity in bending | Longitudinal grain | N/mm² | EN310 | 5137 |

Cross grain | N/mm² | 4132 | ||

Bearing concrete pressure | KN | EN310 | 70 | |

Application

For concrete forming of circular columns

Installation

Treat inner ply film with concrete release agent firstly.

Fix the steel belts horizontally according to the lines.

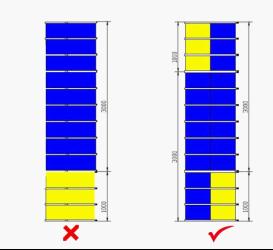

If the height is more than 3000mm , please install it as the indication below.

From feedback on site, only 2 skilled workers can install 15 circular columns in 8 hours.

Inner Diameter | Interval of steel belts |

300mm-950mm | 300mm |

1000mm-1450mm | 250mm |

1500mm-1600mm | 200mm |

Dismantling

Simply untie the steel belts and the ply will separate easily.

Maintenance & Storage

Lightly treat the ply film with oil before next usage.

place the formwork vertical, away from direct sunlight and water.

Packing

one bundle by 6 pieces, inside craft paper and waterproof shrinking film, outside bag.

Pictures on site

Product recommendation