OEM Hydraulic Banjo Fitting

| Trade Term: | FOB,CFR,CIF,EXW |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 600000 Piece/Pieces per Month stock |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | 1CT-SP/1DT-SP Hydraulic Adapters And Metric Tube Adapter, 45° Elbow JIC 74°cone/ BSPT Male Adapters, 90° Elbow JIC Male 74° Cone/ NPT Female Adapters, BSP Male Double Use For 60° Cone Seat Or Bonded Seal/NPT Female Adapters, BSP Male Double Use For 60° Cone Seat Or Bonded Seal/ JIC Female 74° Seat Adapters |

Product Detail

| Means of Transport: | EXPRESS, Ocean, Air |

|---|---|

| Type: | Hydraulic Accumulators |

| Brand Name: | OEM |

| Material: | Carbon steel |

| Technics: | Forging and machining |

| Flange Size: | G1/8"X28 to G1"x11 |

| Hose DN: | 5 to 25 |

| Hose dash: | 03 to 16 |

| Finish: | Cr+6 free Zinc plated |

| Medium: | water, oil, gas, chemical engineering |

| Price term: | FOB Ningbo, CIF |

| Payment: | T/T or L/C |

| Port: | Ningbo |

| Production Capacity: | 600000 Piece/Pieces per Month stock |

| Packing: | in a carton, then a plastic bag, last in a wooden case |

| Delivery Date: | 45-60days |

Product Description

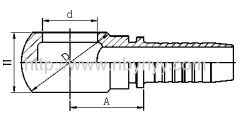

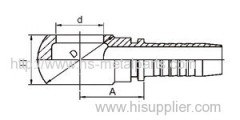

| PART NO. | Flange Size | DN | Dash | A | d | D | H |

| 72011-02-03 | G1/8"X28 | 5 | 03 | 18 | 9.9 | 22 | 16 |

| 72011-02-04 | G1/8"X28 | 6 | 04 | 18.5 | 9.9 | 22 | 16 |

| 72011-04-03 | G1/4"X19 | 5 | 03 | 19 | 13.3 | 24 | 15 |

| 72011-04-04 | G1/4"X19 | 6 | 04 | 19.5 | 13.3 | 24 | 15 |

| 72011-04-05 | G1/4"X19 | 8 | 05 | 19.5 | 13.3 | 24 | 15 |

| 72011-04-06 | G1/4"X19 | 10 | 06 | 19.5 | 13.3 | 24 | 15 |

| 72011-06-04 | G3/8"X19 | 6 | 04 | 22 | 16.7 | 29 | 20 |

| 72011-06-05 | G3/8"X19 | 8 | 05 | 22 | 16.7 | 29 | 20 |

| 72011-06-06 | G3/8"X19 | 10 | 06 | 22 | 16.7 | 29 | 20 |

| 72011-06-08 | G3/8"X19 | 6 | 08 | 23 | 16.7 | 29 | 20 |

| 72011-08-05 | G1/2"X14 | 8 | 05 | 27.5 | 21 | 38 | 25 |

| 72011-08-06 | G1/2"X14 | 10 | 06 | 27.5 | 21 | 38 | 25 |

| 72011-08-08 | G1/2"X14 | 12 | 08 | 28 | 21 | 38 | 25 |

| 72011-08-10 | G1/2"X14 | 16 | 10 | 29 | 21 | 38 | 25 |

| 72011-10-10 | G5/8"X14 | 16 | 10 | 28 | 23 | 40 | 27 |

| 72011-12-10 | G3/4"X14 | 16 | 10 | 32 | 26.5 | 48 | 31 |

| 72011-12-12 | G3/4"X14 | 20 | 12 | 32 | 26.5 | 48 | 31 |

| 72011-16-08 | G1"X11 | 12 | 08 | 40 | 33.3 | 60 | 42 |

| 72011-16-12 | G1"X11 | 20 | 12 | 40 | 33.3 | 60 | 42 |

| 72011-16-16 | G1"X11 | 25 | 16 | 41 | 33.3 | 60 | 42 |

| Note:1.For use with braided hoses. 2.If use with spiral hoses,hose fitting series number is 70012-xx-xx. | |||||||

We also can supply Banjo fitting similar as follow ones:

EO 24° cone end / Male metric thread with soft seal ring

EO 24° cone end / Male metric thread with metal sealing ring

EO 24° cone end / Male BSPP thread with soft seal ring

EO 24° cone end / Male BSPP thread with metal sealing ring

EO 24° cone end / Male metric thread with soft seal ring

EO 24° cone end / Male metric thread with metal sealing ring

EO 24° cone end / Male BSPP thread with soft seal ring

EO 24° cone end / Male BSPP thread with metal sealing ring

EO 24° cone end / Metric male stud with metal seal ring

EO 24° cone end / Metric male stud with soft seal ring

EO 24° cone end / BSPP male stud with metal seal ring

EO 24° cone end / BSPP male stud with soft seal ring

EO 24° cone end / Male metric thread

EO 24° cone end / Male BSPP thread

EO 24° cone end / Male NPT thread (SAE J476)

EO 24° cone end / Male short metric taper thread (DIN 3852-1, type C)

EO 24° cone end / Male metric thread – metal sealing edge (ISO 9974)

EO 24° cone end / Male BSPP thread – metal sealing edge (ISO 1179)

EO 24° cone end / Male short BSP taper thread (DIN 3852-2, type C)

EO 24° cone end / Male metric thread – metal sealing edge (ISO 9974)

Split Flange 100° Tube Elbow (SAE Code 61)

Split Flange 110° Tube Elbow (SAE Code 61)

Split Flange 135° Tube Elbow (SAE Code 61)

Male Pipe (NPTF) Rigid

British Standard 60° Cone (BSPP) Male Pipe Rigid

FOR-SEAL Male Rigid

Male Pipe Swivel

SAE 37° Male Rigid

Male Straight Thread O-Ring Rigid

Female Swivel 30° Flare Metric Thread (Komatsu, Linkbelt, etc.)

British Standard (BSPP) 60° Cone Female Pipe Swivel

Female FOR-SEAL Swivel Straight

READY-LOK Male Connector (For Deep Mining Markets)

Split Flange Straight (SAE Code 61)

Split Flange Straight (SAE Code 62)

British Standard 60° Cone (BSPP) Female Swivel 45° Tube Elbow

Split Flange 22-1/2° Tube Elbow (SAE Code 61)

JIC 37° Female Swivel 45° Tube Elbow (Refer to Footnotes)

Split Flange 30° Tube Elbow (SAE Code 61)

Female FOR-SEAL Swivel 45° Tube Elbow

JIC 37° Female Swivel 60° Tube Elbow

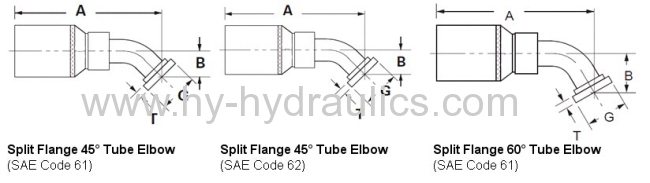

Split Flange 45° Tube Elbow (SAE Code 61)

Split Flange 45° Tube Elbow (SAE Code 62)

Split Flange 60° Tube Elbow (SAE Code 6

British Standard (BSPP) 60° Cone Female Pipe Swivel 90° Elbow

JIC 37° Female Swivel 90° Tube Elbow (Refer to Footnotes)

Female FOR-SEAL Swivel 90° Short Drop Tube Elbow

Female FOR-SEAL Swivel Long Drop 90° Tube Elbow

Split Flange 90° Tube Elbow (SAE Code 61)

Split Flange 90° Tube Elbow (SAE Code 62)

Design and Construction

Forging and maching process for shaped products of elbows, tees and crosses, while cold drawn barstock is for the staights.

Most of our Connector products are made of carbon steel, brass, but also they can made of stainless steel or other material under the drawing of customers.

Finish

Zinc plating with silver chromate (zinc chromium 6 free) is used on all standard steel products. Stainless steel fittings are passivated.

Zinc and Nickel plating, electroless Nickel plating are also alternative options

High Quality Standards

As an ISO 9001 certificated manufactory, we ensure that our design and manufacturing processes are the highest quality by maintaining proper certification and in-house inspections.

Under the requirement of ISO, we have a rotating gage calibration schedule to make sure the dimensions of each fitting component is 100% accurate based on specified measurements.

We have a professional quality inspection team. Individually trained employees control the manufacturing process with strict statistical analysis and control. We can ensure that each identical fitting component you order is true to the design specifications.

Packaging and Shipping

All Huayan orders are packaged in-house by our employees in strong cartons wrapped in protective caps. All packages are clearly labeled with text and bar information. Then we will put boxes into an wooden case with a big plastic bags.

As usually we delivery order 45-60 days after the order. Customers may also inquire about our Just-In-Time manufacturing process or expedited manufacture and shipping for products needed within 24 hours.

Customer Service

Our website will also help guide you through the various metal types of hydraulic fittings and more. Provide us with a faxed or email sketch of your required hydraulic fitting components along with the desired quantity and we will be able to give you a quote within 24 hours.

Thank you for visiting Hua Yan Hydraulics!