AC Frequency Converter Vector Inverter Crane Drive

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 10000 set per month |

| Place of Origin: | Hubei |

Company Profile

| Location: | Wuhan, Hubei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | VFD, Variable Frequency Drive |

Product Detail

| Model No.: | HID620A |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Type: | DC/AC Inverters |

| Output Type: | Triple |

| Output Power: | >500W |

| Brand Name: | Hiconics |

| Size: | customized |

| Weight: | customized |

| Input Voltage: | 380v |

| Output Voltage: | 380v |

| Control Method: | V/F control, VC, SVC |

| Input Power Type: | Three phase AC |

| Output Power: | 0.4kw-630kw for 380V |

| stock temperature: | -25C-+65C |

| application: | for various kinds of cranes |

| delivery port: | Shanghai, Guangzhou or other ports you request |

| delivery date: | 7 days after receiving deposit |

| package: | polywood cartoon |

| certificate: | CE, ISO9001:2008 |

| rated frequency range: | 0-300Hz |

| Production Capacity: | 10000 set per month |

| Packing: | polywood cartoon of different sizes |

| Delivery Date: | 7 working days after payments |

Product Description

Frequency Converter,AC Frequency Drive,Frequency Inverter

Product Description

Hiconics HID620A series VFD are specially designed for crane industries on the basis of HID600A vector control system. It has not only combined innovative compact structure design with superior performance and rich application function that of HID600A together, but also adopted logical controlling function of the cranes, which largely simplified the design of the system and decreased cost of users in a large extent.

Application Field

1. All kinds of hoisting machinery in the fields of ports, metal processing field, electric power industry, machinery, architecture, chemical industry, transportation, energy, light industry, environment protection, and Water conservancy, etc.

2. Engineering Cranes applied in railways and highways construction..

3. Mining Machinery used in various kinds of mining hoist, winding machine, etc.

Function Features

1. Synchronization technology of primary device and slave unit

This technology is mainly used in the situation of many VFDs with many motors drive one hoisting machine, which is trying to keep speed, overload rate and location of every motor in harmony with each other.

2. Torque memorizing function

Every time when the brake is closed, the machine will record the output torque of the motor. Then when the brake opens next time, the VFD will automatically give out the recorded output torque to avoid hook slipping phenomenon.

3. Reliable protection function

A series of protection functions like hook slipping prevention design, overload protection, stalling protection, zero position protection, over speed protection, over voltage, under voltage or over current protection, input or output default phase protection, output faults protection and feedback fault protection while the brake is closed are adopted.

4. Automatic adjustment function of speed according to the load

The speed could be adjusted according to the weight of the load and realize the requirement of light load fast, heavy load slow.

5. Swing preventing function

This function could achieve speed control and precise fixation of light load, reduce accelerating time and impact or abrasion to the machine and improve working efficiency.

6. Self-learning function

Self-learning function could be carried out both in static and rotating state.

7. Various communication methods supported

RS-485 communication function is adopted as standard configuration and T-DP01 interface card as optional card, they could be used in the PROFIBUS-DP field bus communication.

8. Logical control of brake chronological order

Unique and reliable brake control order and brake time adjustable could effectively avoid hook slipping phenomenon and ensure the security of workers and equipments.

9. Low speed with high torque

Function of Low speed with high torque could be realized even without transducer, which is quite difficult before.

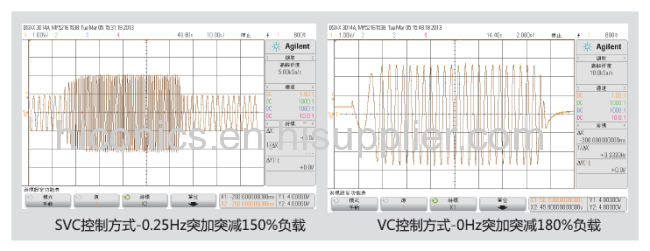

High performance open loop/closed loop control: 0.25Hz 150% rated torque output for open loop; 0Hz 180% rated torque output for closed loop.

Variable Frequency Cabinet for Architectural Hoister

Hiconics Company has specially designed variable frequency switch cabinet for architectural hoister to realize stepless speed regulation and stable running of the hoister. The new frequency cabinet could offer users an overall solution, avoid hook slipping phenomenon, reduce mechanical impact and improve working efficiency.

Traditional Architectural Hoister | Hoister equipped with variable frequency cabinet |

Functions of acceleration, deceleration and stop of machine was achieved through contactor plus relay; speed hard to control, large impact during start and stop of machine could not be avoided; running speed unadjustable and unstable stop of machine would affect profit of users. | The cabinet could realize stepless speed regulation during accelerating, decelerating and braking process of the machine and reduce impact to the mechanical system during the start or stop of machine, the stability and comfort feeling during the running process largely improved, hoister service life lengthened and working efficiency promoted in a large extent. |

Traditional control method adopted might cause hook slipping phenomenon because of lacking of torque during the start and stop of machine. | Could effectively avoid hook slipping phenomenon that might appear in traditional control method, the impact among mechanical systems are largely improved. Stability during running process and working efficiency have promoted as well. |

The architectural elevator was used to lifting materials and special protection method should be carried out during its working period. | The newly designed frequency cabinet put variable frequency drive, electrical switches, protection elements and limiter into one integrated cabinet. Only connections of grid input, switch control signal and motor output need to be carried out while using. It has the advantages of simple connection, convenient operation, high reliability, easy installation, etc. |

Variable Frequency Cabinet for Winding-type Double Hook Bridge Crane

According to the demands of our clients, Hiconics has also developed variable frequency cabinet for winding –type double hook bridge crane. This kind of VFD has installed frequency drives of accelerating and decelerating, moving, amplitude varying, rotating and grabbing bucket and has realized integrated variable frequency control of both large and small load, both main hook and auxiliary hook. We have added braking units especially for hoisters to realize a fast start or stop of hoister. The operational methods of wireless remote control, wired remote control and cab operation could be applied at the same time.

Application Advantages

Integration: It has four functions of hoisting, rotating, amplitude varying and walking. Users can switch these four functions by changing the parameter.

Independent control: Each of those four systems (hoisting, rotating, amplitude varying and walking) could be controlled independently, which improves the reliability and security of the system.

Flexible collocation: The PLC function makes it convenient for users to install flexibly by setting the parameter of the VFD.

Professional design: Functions like slip compensation and adjustable torque, sequential logic control and hook slipping avoidance offer professional solutions to users.

Easy to maintain: Clear circuit makes it easy to examine the wire and the fault code is convenient for workers to solve the problems quickly.

Low cost: Using IGBT instead of the positive and negative switching contactor, and the braking unit instead of cutting resistor contactor. The perfect protecting function can ensure the safety of the motor, so that the maintaining cost is reduced.

Main spare parts

NO. | Name | Low Power | Origin Place | High Power | Origin Place |

1 | IGBT | Infineon | Germany | Infineon | Germany |

2 | Rectifier Bridge | SL(Siling) | China | (Siling)/Infineon | China/Germany |

3 | Electrolytic Capacitor | Jianghai/Kingbox | China/Japan | Jianghai/Kingbox | China/Japan |

4 | Hall Sensor | Zhong Xu | China | LEM | Switzerland |

5 | ICEL | CDE | America | CDE | America |

6 | DC Contactor | Tianshui | China | Tianshui | China |

7 | Fan | ADDA | Taiwan | ADDA | Taiwan |

8 | DSP | TI | America | TI | America |

Why Choose Us???

1. Our products have patents right and many qualified certificates

2. The design team are quite professional and skilled

3. We have our own researching base

4. We have perfect after service teams

Trade Terms

a. Delivery term

We will delivery for you after you done the full payment within 3 to 15 working days

b. Payment

For small order by air or by express, it is 100% T/T in advance.

For large order by ocean, 30% deposit of the order value should be paid, 70% of the balance payment should be done before delivery

c. Packing

Unless otherwise stated in the offer, the prices include packing in accordance with Hiconics customary standard of packing.

Certificate