HID618A Series, AC Frequency Drive, Frequency Converter, Inverter, Transducer, Injection Molding Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 10000 set per month |

| Place of Origin: | Hubei |

Company Profile

| Location: | Wuhan, Hubei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | VFD, Variable Frequency Drive |

Product Detail

| Model No.: | HID618A |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Type: | DC/AC Inverters |

| Output Type: | Triple |

| Output Power: | >500W |

| Brand Name: | Hiconics |

| Size: | customized |

| Weight: | customized |

| Input Voltage: | 380v |

| Output Voltage: | 380v |

| control method: | VC control |

| keypad: | LED/LCD |

| protecting grade: | IP20 |

| stock temperature: | -25C-+65C |

| frequency control scope: | 0-300Hz |

| delivery port: | Shanghai, Guangzhou or other ports |

| delivery date: | 15-20 days |

| certificate: | CE,ISO9001:2008 |

| overload capacity: | 60s for 150%,1s for 180% |

| package: | polywood case |

| Production Capacity: | 10000 set per month |

| Packing: | polywood case of different sizes |

| Delivery Date: | 7 working days after payments |

Product Description

HID618A Series, AC Frequency Drive, Frequency Converter, Inverter, Transducer, Injection Molding Machine

Product Description

Hiconics HID618A Series VFD adopts the most advanced and mature vector control algorithm at the present and special controlling card for injection molding system is used in the machine for the controlling of gas-electric hybrid injection molding system. It has been through a series of strict tests like group pulse test, EMC test and vibration test and could adapt all kinds of bad working environments. With relatively high pressure responding speed and pressure keeping precision, our products could meet the demands of taking shape rapidly and precisely and saving energy as well.

Application Field

Injection Molding Machine, Oil Compressor, Shoe Making Machine, Die-casting Machine, Brick Manufacturing Machine, Material Extruder, Blowing Machine, Packaging Machine, Bending Machine, Cutting Machine, etc.

Working Principle of the System

The hydraulic servo system is composed of servo drive, servo motor, oil pump, pressure transducer, injection molding machine, etc. It uses new type servo control technology of building control method of flow and pressure to instead of constant volume pump valve control method of traditional asynchronous motor, which could not only reduce the electrical energy consumption of the system but improve the working efficiency and lengthen service life of the system as well.

Function Features

1. Saving cost

l Paralleling combination technology of multiple pumps is adopted to get large current flow to drive large machine, which could reduce cost.

l Energy consuming components of proportional pressure valve and proportional flow valve are completely removed to simplify hydraulic pipeline.

l The built in braking units could reduce the installation size and save cost as well.

2. Simple Operation

l Smart control System introduced in the VFD could ensure a direct use of the product without debugging or maintenance process.

l LED/LCD operation panel could save the changed parameter automatically.

3. Low Noise

The noise could be quite low during the running process and it could be even lower while in slow running process, usually less than 70 decibel.

4. High Reliability

l Best protection control could make sure that the system run to the largest extent in a short time.

l The drive has been through Antijamming processing and PG card could adapt various kinds of bad working environments.

l The product is suitable for the AC voltage from 310v to 420v and could meet the demands of varied grid or voltage of different area in China.

5. Lengthening Service Life of the Product

l The oil temperature rise of the system is largely decreased and the use of cooling water could be avoided or reduced, which could lengthen service life of hydraulic components.

l Various protective functions like over-voltage, over-current and default phase to the motor could lengthen service life of the machine and mould.

l The impact of unlocking or locking mould is largely reduced and service life of the machine and mould largely lengthened.

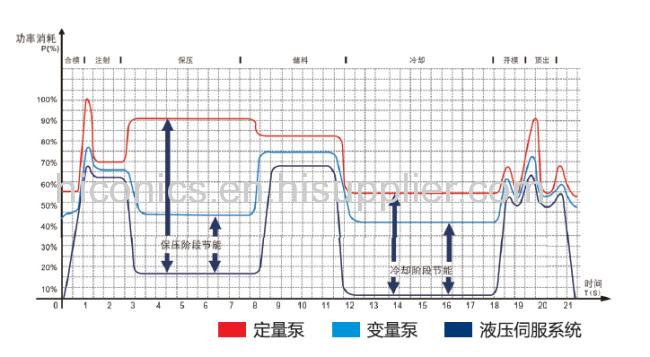

6. Saving Energy

The output flow of traditional constant flow pumps is fixed and could not be adjusted according to the actual demand. When the load needs a relatively small flow, the unnecessary flow will flow back to the oil tank with the help of proportional current valve and proportional voltage valve, which will waste a lot of oil. However, the hydraulic servo drive could direct the oil pump to offer oil according to the actual demand, which could avoid the situation of waste of oil and will save 40%-65% energy and 80% at most compared with constant flow pumps.

|

7. Perfect Performance

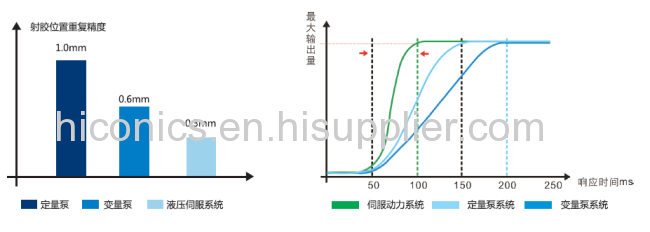

l Various methods like vector control, fuzzy PID, pump leak oil pressure compensation are adopted to ensure a high precise of plastic injecting place within ±0.3mm, fluctuation of pressure less than ±0.5bar, responding time of the system as low as 0.05s. Both working efficiency and qualified rate of the product are improved.

l The output current and output torque is 2.5 times that of the rated value, thus could make sure that the machine would not jump during high pressure plastic injecting process and heavy load process and keep a good quality of the products.

Product Model

Model | Input Power:3AC 380V±15% | Braking Unit | ||

Load Type:Constant Torque/Heavy Load | ||||

Overload Capacity:150%rated current 60s 180%rated current 1s | ||||

Rated Output Power (kW) | Rated Input Current (A) | Rated Output Current (A) | ||

HID618A-T4-7.5C | 7.5 | 20 | 17 | Built-in |

HID618A-T4-11C | 11 | 26 | 25 | Built-in |

HID618A-T4-15C | 15 | 35 | 32 | Built-in |

HID618A-T4-18.5C | 18.5 | 38 | 37 | Built-in |

HID618A-T4-22C | 22 | 46 | 45 | Built-in |

HID618A-T4-30C | 30 | 62 | 60 | Built-in |

HID618A-T4-37C | 37 | 76 | 75 | Built-in |

HID618A-T4-45C | 45 | 92 | 91 | Built-in |

HID618A-T4-55C | 55 | 113 | 112 | Built-in |

HID618A-T4-75C | 75 | 157 | 150 | Built-out |

HID618A-T4-90C | 90 | 180 | 176 | Built-out |

HID618A-T4-110C | 110 | 214 | 210 | Built-out |

HID618A-T4-132C | 132 | 256 | 250 | Built-out |

Technical Parameters

Items | Specification | |

Control Performance | Frequency control range | 0~300Hz |

Output frequency precision | 0.01Hz | |

Set Frequency resolution | Digital set: 0.01Hz Analog set: AD Conversion precision for 1‰ | |

Speed control range | 1:1000 | |

Speed control precision | ±0.02% | |

Control method | Synchronous motor closed-loop vector control | |

Start-up Torque | 0Hz 180% | |

Start torque | 1Hz-150% rated torque, 0Hz-200% rated torque | |

Overload capacity | 150% rated current 60s;180% rated current 1s | |

Frequency resource option | Digital set, analog voltage set, analog current set, series communication set, available to switch | |

Input Terminal | 5 digital input terminal; 3 analog input terminal, available for voltage 0-10v; 1 unit of over-heat protection input terminal connected with inside thermal resistor; PG card signal terminal | |

Output Terminal | 2 relay output terminal; 2 analog output terminal | |

Protection Function | Over voltage or under voltage protection, Over current protection, modular protection, over heat protection, over load protection, EEPROM abnormal, Relay abnormal | |

Distinctive Function | Automatic Voltage Regulation (AVR) | When the voltage of the grid varies, a constant output voltage could be kept |

Power up Self-checking Function of Drive | This function could achieve security protection inspection of peripheral equipments like open circuit, ground connection and short circuit, etc | |

Motor Need not Debugging | Debugging parameters have been well packaged and motor need not be debugged | |

Uploading and downloading Functions of Oil Pressure Parameter | The set oil pressure parameter could be uploaded and downloaded to other VFDs of the same type and debugging time could be largely saved | |

PID Fuzzy Self-adjusting Function | Perfect PID fuzzy self-adjust function makes sure that the default parameter be suitable for vast majority of VFDs without adjustment | |

Keyboard with both Chinese and English | Keyboard with both Chinese and English could be offered and operation much more convenient | |

Human-Machine Interaction Function | Human-Machine Interaction Function could be achieved through CAN communication | |

Support Manufacturing Management Networking System | Networking Management of many VFDs with many drives work together could be achieved, then capacity, energy consumption and schedule could be learned about timely | |

Running Environment | Protection grade | IP20 |

Installation site | Vertically installed in cabinet, no dust, no corrosive gas, no flammable gas, no oil fog, no steam, no drop water, no direct sun light | |

Working temperature | -10°C~+40°C(derating use if ambient temperature higher than 40 degree, maximum is 50 degree. 1% derating every 1 degree higher than 40 degree. | |

Altitude | 0~2000m, derating use above 1000m, rated output current reduce 1% every 100m higher | |

Relative humidity | 20%~90%RH( no condensation) | |

Vibration | <5m/s^2(0.5g) | |

Stock temperature | -25°C~+65°C | |

Trade Terms

a. Delivery term

We will delivery for you after you done the full payment within 3 to 15 working days

b. Payment

For small order by air or by express, it is 100% T/T in advance.

For large order by ocean, 30% deposit of the order value should be paid, 70% of the balance payment should be done before delivery

c. Packing

Unless otherwise stated in the offer, the prices include packing in accordance with Hiconics customary standard of packing.

Why Choose Us???

1. Our products have patents right and many qualified certificates

2. The design team are quite professional and skilled

3. We have our own researching base

4. We have perfect after service teams

Certificate