HID600A Series, Adjustable Frequency Drive, frequency changer, AC Drive, Energy Saver

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 10000 set per month |

| Place of Origin: | Hubei |

Company Profile

| Location: | Wuhan, Hubei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | VFD, Variable Frequency Drive |

Product Detail

| Model No.: | HID600A |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Type: | DC/AC Inverters |

| Output Type: | Triple |

| Output Power: | >500W |

| Brand Name: | Hiconics |

| Size: | customized |

| Weight: | customized |

| Input Voltage: | 380v,660v |

| Output Voltage: | 380v,660v |

| power range: | 0.4kw-1mw |

| control method: | V/F,VC,SVC |

| product type: | heavy load type,light load type |

| stock temperature: | -25C-+65C |

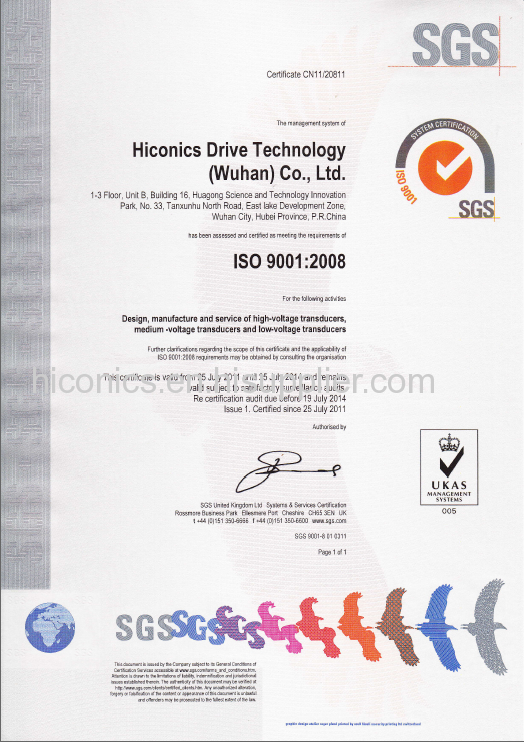

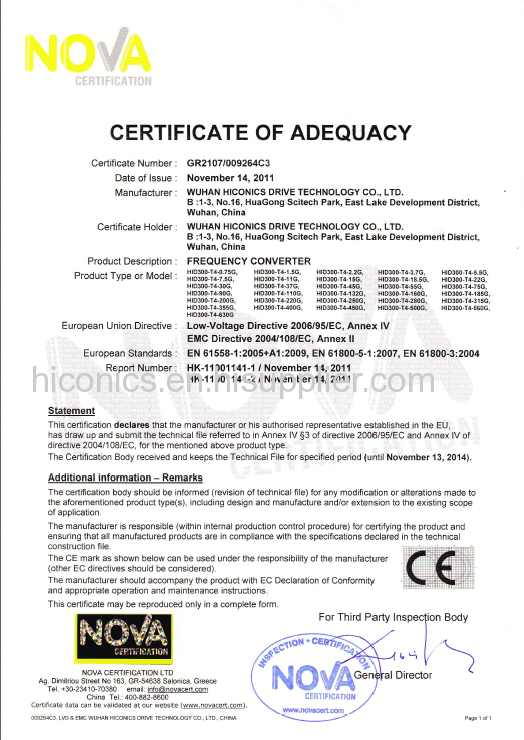

| certificate: | CE,ISO9001:2008 |

| delivery port: | Shanghai, Guangzhou |

| delivery date: | 7 working days after payment |

| application 1: | mining used machinery like ball mill,belt convery |

| application 2: | metal processing machinery like lathe machine |

| application 3: | oil pump,construction,rubber processing machinery |

| Production Capacity: | 10000 set per month |

| Packing: | polywood cartoon of different sizes |

| Delivery Date: | 7 working days after full payments |

Product Description

HID600A Series, Adjustable Frequency Drive, frequency changer, converter inverter

Power Range: 0.4KW~1MW/220V/380V/690V

Product Description

Hiconics HID600A Series High Performance Vector Control VFD could meet almost all the demands of the current fields like high performance, high reliability, high flexibility and high expansibility, etc. It could be widely used in the speed control of AC asynchronous motor, permanent magnet synchronous motor and spindle motor. With many advanced functions and special design adopted, this kind of VFD could offer solution according to current situation of clients with lower cost.

Application Field

1. Mining Used Machinery

2. Metal Processing Machinery

3. Textile Machinery

4. Oil Pump Used Machinery

5. Construction

6. Rubber Processing Machinery

7. Injection Molding Machinery

8. Crane Hoist Machinery

Function Features

1. Permanent Magnet synchronous Open Loop Vector Control Adopted

Open loop vector control method is adopted in the controlling of permanent magnet synchronous motor to reduce faults in site with simple wiring connection and high precise of speed control.

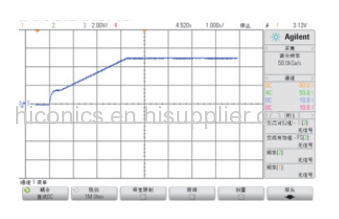

2. Superior Responsiveness

Vector variable frequency controlling technology could achieve superior dynamic responsiveness. This function could make sure the VFD responds to the set speed quickly and the system follows the change of load immediately, thus increasing operating efficiency of the system.

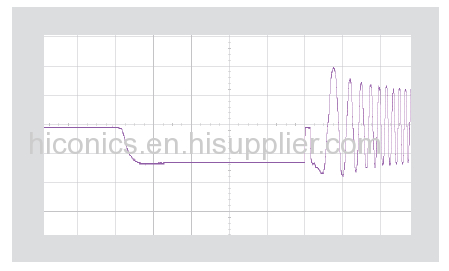

3. Perfect Over-Current/Over-Voltage Prevention Function

With perfect transient current/voltage controlling capacity, the machine could ensure a relatively stable operation of system without sudden trip during fast accelerating or decelerating of speed or load fluctuation.

4. Background Monitoring Software Adopted

The oscilloscope function of background monitoring software could observe the real-time running state of VFD efficiently, which is convenient to debug on site.

5. Parameter Copy Function of Keyboard

The set parameter could be copied through the keyboard and uploaded or downloaded to the same model of VFD, which could simplify parameter setting operation.

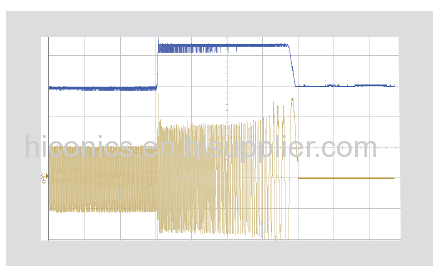

6. Overmodulation Function

Compared with traditional sinusoidal modulation, PWM Overmodulation function could improve use ratio of bus voltage and increase output power of VFD. It could be used in the environment of low power grid voltage, long-term overload or impact load.

Stand Bus Voltage (V) | Actual Bus Voltage (V) | Operation Frequency (Hz) | Status of Overmodulation | Tested Voltage of Power Analyzer (V) |

537 | 476 | 50 | Not open | 352 |

Open | 378 |

7. Rich Control Method

1. VC control method: suitable for high precise of speed control occasion

2. SVC control method: suitable for asynchronous motor, variable frequency motor

3. V/F control method: suitable for the occasion of variable frequency drive with many motors

8. Various Braking Method

1. Decelerating DC braking: could realize a fast and stable stop with high precise, suitable for cranes, mining used hoist.

2. Starting-up DC Braking: suitable for occasions of braking motor before starting-up action in order to remove irregular rotation caused by external factors, like large-size fan.

3. Dynamic Braking: suitable for 0.75-15kw built-in braking units of all sizes. When a fast stop of machine is needed, braking resistor could be directly connected. This braking method could be used in frequent braking occasion of high inertia load.

4. Magnetic Flux Braking: Its working principle is to turn kinetic energy into thermal energy and consume the thermal energy in the rotor of motor. This function could effectively restrain the increase of bus voltage during braking process. This method is suitable for fast stop of machine of infrequent start-up or stop of high inertia load.

Why Choose Us???

1. Our products have patents right and many qualified certificates

2. The design team are quite professional and skilled

3. We have our own researching base

4. We have perfect after service teams

Certificcate

About Our Company