100W Explosiong-proof led highbay light fixture

| Place of Origin: | Zhejiang |

|---|

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | ZS-HB-100W |

|---|

Product Description

Product name:100W Explosion-proof led highbay light fixture

Model:ZS-FB-100W

Led brand:Epistar or Bridgelux

Driver:Meanwell driver

CRI:over 80Ra

IP Rating:IP65

Features:

Using high power COB LEDS, the lamp's luminous efficiency can reach 80-100LM/W, and CRI>80Ra; Fins heating dissipation design enables the LED Tj within 85℃ , and power up to 200W, lifespan more than 35,000 hours; with protecting rate:IP65.

The explosion high bay light is verified and certified according to standards for safety as below: GB3836.1-2010. Explosive atmospheres Part 1: Equipment General Requirements GB3836.8-2003 Explosive atmospheres. Part8: Electrical apparatusfor explosive gas atmos-pheres-Part8: Encapsulation "n" with Ex-marking ExnRⅡT4Gc.

The light can be used in: Normally, a place in which an explosive atmosphere in the form of explosive dust or combustible fiber in mixture with air is likely to occur continuously or frequently in short time, or for long periods in normal operation. According to the classification of explosion proof grade and application, the light can be use in Zone2.Surface temperature of item for safety:≤135℃,such an area lighting site like factory, warehouse, except mine.

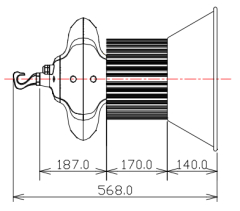

Front view:

---Front view of this explosion proof led highbay light

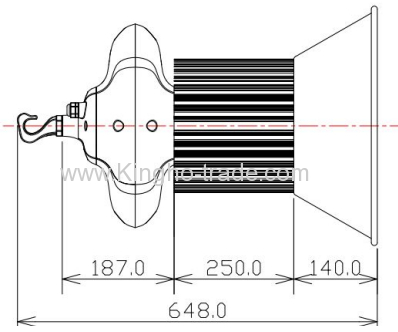

Physical size:

---physical size of 100W explosion-proof led highbay light fixture

Shell Material:Aluminum Alloy

Shell Color:silver white

Net weight:8.3Kg

Unit:mm±2mm

Explosion-proof Parameters:

Explosion-proof(Grade): ExnRⅡT4Gc

Ex—Explosion-proof;

nR—Explosion proof form code of explosion proof electric equipment, nR for restrict breathing type, the others: D for explosion suppression type; IA for flameproof intrinsically safe type; MB for pouring type … .;

Ⅱ—Explosion proof electrical equipment is divided into typeⅠ, Ⅱ, Ⅲclass; class I used for coal mine gas environment; class II, III used for other explosive gases electric equipments except coal mines which can easily generate gas.

T4—Electrical equipment external surface temperature range ( T4 means the temperature of any point on the external surface of explosion-proof mining lamp ≤ 135 ℃);

Gc—Electric equipment protection level, and has a corresponding relationship to its used place, Gc level of protection for the general, and it can be used in explosive gas environment –Zone 2;

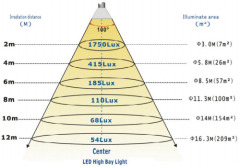

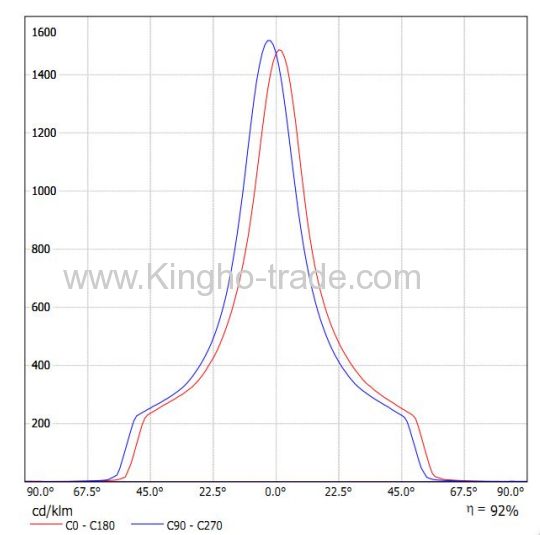

lux reading:

---lux reading of 100W explosion-proof led highbay light fixture

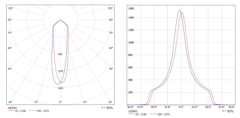

photometric of 100W explosion-proof led highbay light fixture

Hazardous area classification:

Explosive substance | Area definition | Chinese standard | Foreign standards |

Gas(ClassⅠ) | Under normal circumstances, the explosive gas mixture continuously or long time existence. | Zone 0 | Div.1 |

Under normal circumstances, the explosive gas mixture is likely to existent site | Zone 1 | ||

Under normal circumstances, the explosive gas mixture is not possible appear, Only in abnormal circumstances, occasionally or short time existed site ; | Zone 2 | Div.2 | |

Dust or fiber (ClassⅡ/ClassⅢ) | Under normal circumstances, explosive dust or combustible fiber and air mixture may be continuous, a short time frequent appear or long time existence. | Zone 10 | Div.1 |

Under normal circumstances, explosive dust or combustible fiber and air mixture can not appear, just in case of abnormal condition, occasionally or short time appears. | Zone 11 | Div.2 |

Gas temperature group

Temperature category | Explosion proof electrical equipment surface temperature | Common explosive gas |

T1 | ≤450℃ | Methane,Toluene,Methyl ester,Ethane,Propane,Acetone,Acrylic acid, Benzene,Styrene,Carbon monoxide,Ethyl acetate,Acetic acid,Chlorobenzene, Methyl acetate,Ammonia,Acrylic ester,Two ether, City gas,Hydrogen,Water gas |

T2 | ≤300℃ | Methanol,Ethanol,Ethyl benzene,Propyl alcohol,Propylene,Butyl alcohol,Butane,Butyl acetate ,Amyl acetate,Cyclopentane,Butadiene,Epoxy propane,Ethylene,Acetylene |

T3 | ≤200℃ | Pentane,Amyl alcohol,Hexane,Hexyl alcohol, Heptane,Octane,Ring of ethanol,Turpentine oil, Naphtha,Petroleum (gasoline ),Fuel oil,Amyl alcohol four, Two ether,Acrolein,Hydrocarbon |

T4 | ≤135℃ | Acetaldehyde,Tetrafluoroethylene,Trimethylamine,Ethyl ether,Two ether |

T5 | ≤100℃ | Carbon disulfide |

T6 | ≤85℃ | Acid ethyl ester, Nitrous acid ethyl ester |

This series explosion-proof lamp temperature group is T4, according to the above standard data, this series lamp can be used in the warehouse, workshop in the scope of T1, T2, T3, T4, and related places that require explosion-proof lamp lighting can be applied.

Parameters:

Input Voltage | AC100~240V | Color Rendering Index | Ra>80 |

Frequency Range | 50~60Hz | Beam Angle | 60° |

Power Factor | >0.97 | LED Reduction Rate | 1~3% / 1,000Hrs |

Power Efficiency | >92% | Color Temperature | 2700~7000K |

LED Working Voltage | DC30~36V | Working Temperature | -20℃~+45℃ |

LED Power | 150W | IP Grade | IP65 |

Total Power | 163W | Working Life-span | >35000H |

Luminous Efficiency | 80-100lm / W | Power line | VDE 3×1.5mm2 |

Connect wires | Brown→L Blue→N Yellow or Green→G | ||

Luminous flux reduction diagram

---luminous flux reduction diagram of 100W explosion-proof led highbay light fixture

The data above was testing at environment temperature of 25 Celsius degree after 1000 hours constant lighting.

The environment condition will affects luminous flux reduction. Luminous flux will drops faster at a higher temperature or a longer lighting time.

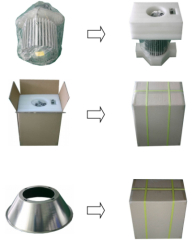

Packing specification:

1,Body(L)412×(W)312×(H)508mm 1PC/CTN 13.5Kg

2,Reflector(L)432×(W)432×(H)534mm 10PCS/CTN 4.5Kg

---packing of this explosion proof led highbay light

Using and installation instructions

---installation of explosion-proof led highbay llight

Installation Procedures

1 Please firstly install the reflector properly on the heat sink, and screw down.

2 Then screw down the hoop into the top cap.

3 Hang the body lamp on the installation site.

4 Please hang the chaining steel wire on another installation device.

5 Connect Live Wire/Null Wire/Ground Wire to electric cable properly and switch on.

Attentions:

1 A licensed electrician must undertake this installation. Please check the lamp carefully before installation,Forbidden to open the lid when charged;

2 Please follow up the installation procedures, make sure the screws been wrested very tightly, the wires been connected properly, as attached installation instruction.