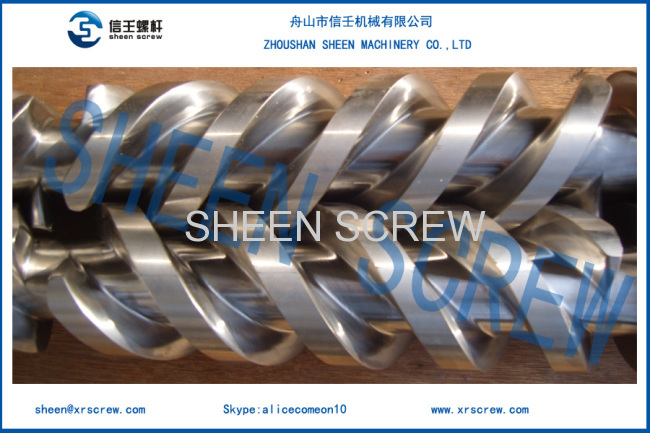

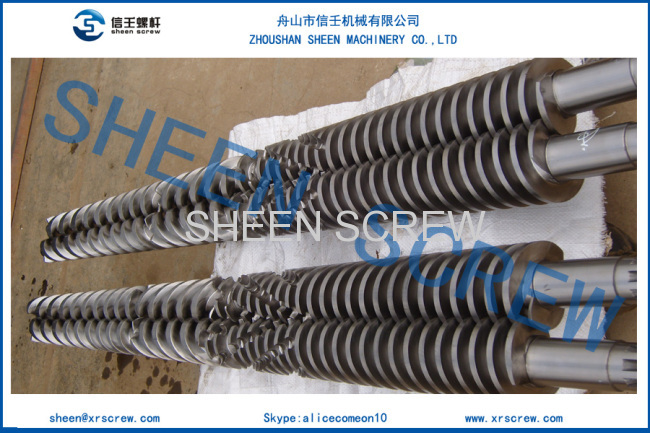

Jwell extruder 65/132 conical twin screw and barrel

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Zhoushan, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screw Barrel, Extruder Screw Barrel, Injection Screw Barrel, Rubber Screw Barrel, Bimetallic Screw Barrel |

Product Detail

| Model No.: | XR-SJZ65/132 |

|---|---|

| Means of Transport: | Ocean, Air |

| Brand Name: | SHEEN SCREW |

| Screw barrel material: | High quality alloy steel 38CrMoALA |

| Screw barrel HS code: | 8477900000 |

| Screw barrel certificate: | ISO9001:2008 |

| Screw barrel application: | PVC Profile extruder |

| Screw barrel nitrided hours: | 120 hours |

| Screw barrel thickness of nitrided layer: | 0.5-0.8mm |

| Screw barrel hardness of nitrided layer: | HV900-1100 |

| Bimetalic material: | tungsten carbige 40% |

| Bimetalic screw processing way: | PTA |

| Bimetallic layer of screw: | 2.5mm |

| Packing: | Film wrapped in wooden case without fumigation |

| Delivery Date: | 25 working days upon receipt of 30% deposit |

Product Description

About SHEEN

Zhoushan Sheen Machiney Company is leading supplier of SCREW and BARREL in china,including designing,manufacturing and sales for these products,we can make any specification of extruder screw barrel and injection molding screw barrel for Haitian,Demag,Engle,Nigrobossi,KMD,NPM,BOY,HUSKY, Nippon Steel, Toshiba, Nissei, Mitsubishi and etc. We also can supply all types of screw and barrel according to your different requirements.

What is our Screw and Barrel advantage:

First:Cretive in designs,our desinging team is very strong,since we have unique culture to motivate them,in order to meet requirement,we work closely to our customer and market!

Second:We have 15 years' experience of manufacturing varied screws, barrels and spares.We are keeping improving our production stytem day by day on the delievey,quality control,all the efforts have improved the customers satisfaction!

Third:We are located in China's screw Town-Jintang,Town in zhoushan city,near to Ningbo Port and Shanghai Port!

Finally,We assure the customer benefits,we supply best quality and competitive price,also best customer service!

Jwell extruder 65/132 conical twin screw and barrel

Φ35/76 | Φ45/90 | Φ50/105 | Φ51/105 | Φ55/110 | Φ60/125 |

Φ65/120 | Φ65/132 | Φ70/140 | Φ75/150 | Φ80/143 | Φ80/156 |

Φ92/188 | Φ 95/ 191 | Φ 105/191 | Φ100/ 200 |

Co-rotating and Counter-rotating)Conical twin screw and cylinder:

Features:Screw and Cylinder adopt blocking structure, can update and maintain comfortably!

Screw&Cylinder also can be made:

CINCINNATI, BATTENFELD, KRUSSMAFFEI, BAUSANO and AMUT model spares!

According to different material and plastic product to choose different compress rate and L/D!

Conical twin screw featurs:

1:Conical twin screw cores water internal circulation series and screw cores oil cold outer cycle.

Screw&Cylinder also can be made:

CINCINNATI, BATTENFELD, KRUSSMAFFEI, BAUSANO and AMUT model spares!

According to different material and plastic product to choose different compress rate and L/D!

Application:

1)PVC sheet extrusion line,From film to plate, from the wafer to the thick slices, calcium powder content more than 5% ;

2)PVC/PPR pipe extrusion line,the calcium powder 80%-120%,150%-200%,250%-300%;

3)PVC profile extrusion line;

4)PVC palletizing extrusion line,Transparent granulation (create particle good diaphaneity, not yellowing - no exhaust

machine barrel),grey granulation (particle good color and luster, full - machine barrel with exhaust)

5)PVC foam production line,PVC free foaming, crust foaming,half crust foaming;

6)PVC/PE wood plastic extrusion line.

Detailed Technical Information:

Base Material | 1)38CrMoAlA(JIS SACM645) 2)Cr12MOV(JIS SKD-11) |

Bimetallic Alloy Materials | 1)Fe-based alloy 2)Ni-based alloy/Deloro alloy |

Double-alloy level | Level A - containing Tungsten of 40% Level B - containing tungsten of 25% Level C - containing tungsten of 9.5% |

Surface Treatment | Heat Treatment High Frequency Treatment Nitriding treatment(120 Hours) Depth of Nitrided Layer: 0.5-0.8 mm Hardness of Nitrided Layer: 900-1020Hv (HRC56°-65°) Hard Chrome Plating treatment: Thickness of Hard Chrome Plating Layer: 0.05-0.10mm Hardness of Hard Chrome Plating Layer: ≥950HV Nickel alloy plating.treatment: Bimetallic Barrel/Cylinder: Centrifugal Casting (Inlay Alloy) Bimetallic Screw: Plasma Alloy Coating Spraying Depth of Bimetallic Layer: >2mm Hardness of Bimetallic Layer: HRC55°-72° |

Basic information | Roughness of the surface:Ra0.4um Linearity of the screw: ≤0.015mm Linear axis limit: ≤0.02mm Hardness after Hardening & Tempering: HB240-280 Fragility of Nitration:≤Two class |

Material Application | 1)General Plastics 2)ABS,PA,PC,PE,PET,PP,PS,EVA,PU,PVC,U-PVC,etc 3)PA + GF(Glass Fiber) 4)Flame-resistant Reinforced Plastics 5)Modified Engineering Plastics 6)All kinds of Mixed Recycled Material(in Scrap or Granule),etc |

General Terms | Means of transport: Ocean,Air,Express Production time: About 25 days after we receive the deposit and lead time will different according to the order quantity! |

Our products advantages | 1)High productivity 2)Wonderful plasticizing 3) low energy consumption 4)Wearable and Durable 5)Fast and On time delivery 6)Best customer service! |

Our Screw and Barrel processing production:

CustomerOrder--ProductDesign(CustomerDrawing)—ProductionFlowArrangement—Material Procurement—Hardening&Tempering—Drilling—RoughTurning—RoughThread Rolling(AlloySprayWelding)—Alignment—FineThreadRolling—Mixing—Alignment—High FrequencyTreatment—Alignment—Polishing—Grinding—120HoursNitridingTreatment—Acid Piclking—Polishing—Chrome Plating—O.D.Grinding—Packaging&Shipping!

Our products package

Oiled,film wrapped in wooden case without fumigation

Our products quality certificate

Our other products:

If you are still looking for suppliers of screw barrel,please contact alice asap,i belive that choosing

us is your best choice,please add my skype id for more information,thanks!